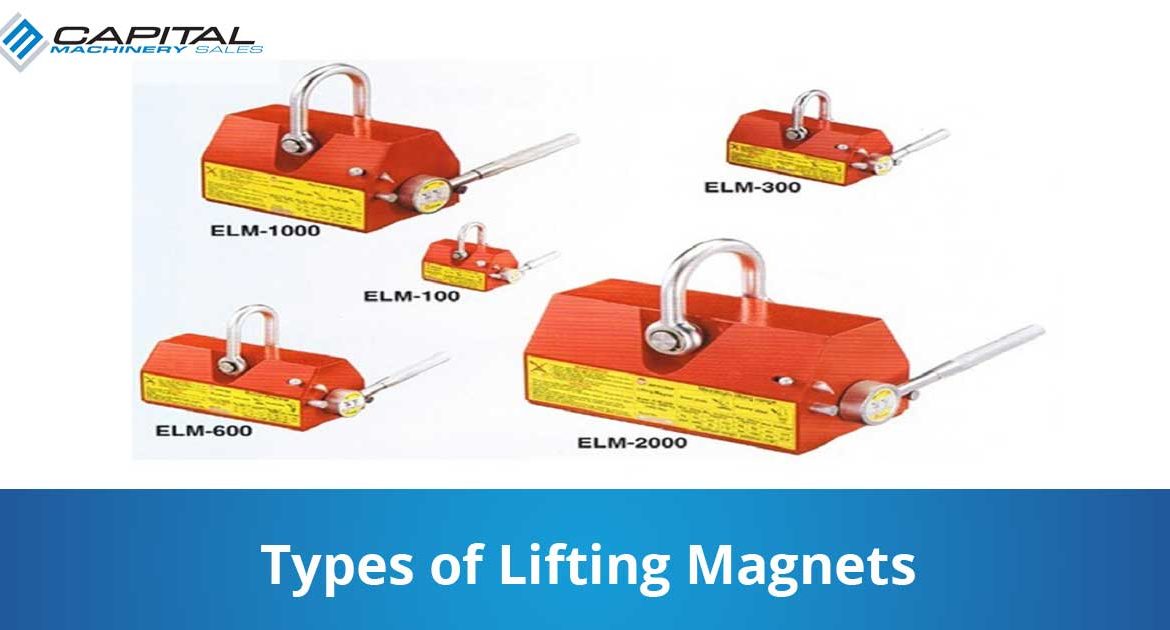

Types of Lifting Magnets

Did you know that there are two types of Lifting Magnets? These are the permanent magnets and the electromagnets. So, let us differentiate the two so we get to know more about their purpose and understand magnets better.

Permanent Magnets – as the name suggest, are permanent. These magnets use a permanently magnetized material to be able to build up the magnetic field.

Permanent magnets used in workshops or work sites generally turn on and off with the use of a lever. They are also good in handling flat materials and rounded parts which can weigh of about 2,200 pounds! These types of lifters are self-contained and are easy to move around to various work sites. The only disadvantage of this type of magnet is that they have a restricted lifting capacity.

Electromagnets – these types of magnets employ electricity to help charge the magnet and be able to hold the material to the surface of the magnet. The electromagnets are using an energized electrical coil wrapped around a steel core to align particles within ferrous materials in a common direction, thus forming a magnetic field.

Electromagnets are made to run on a DC current, which needs a rectifier. Contrary to the permanent magnets, they require a constant power source, which can be considered a drawback or an advantage, depending on its use. Although if there is a power failure, it can be catastrophic! However, some battery back-up systems and universal power supply can address this issue. The one great thing with using the electromagnets is the ability to change the supply of current to the magnet, which allows the user a more flexible option compared to using the permanent magnets.

In the next topic, we will follow-up on the comparison between electromagnets and permanent magnets to help give you an idea on which type of magnetic lifters would be more convenient for you to use in your project.