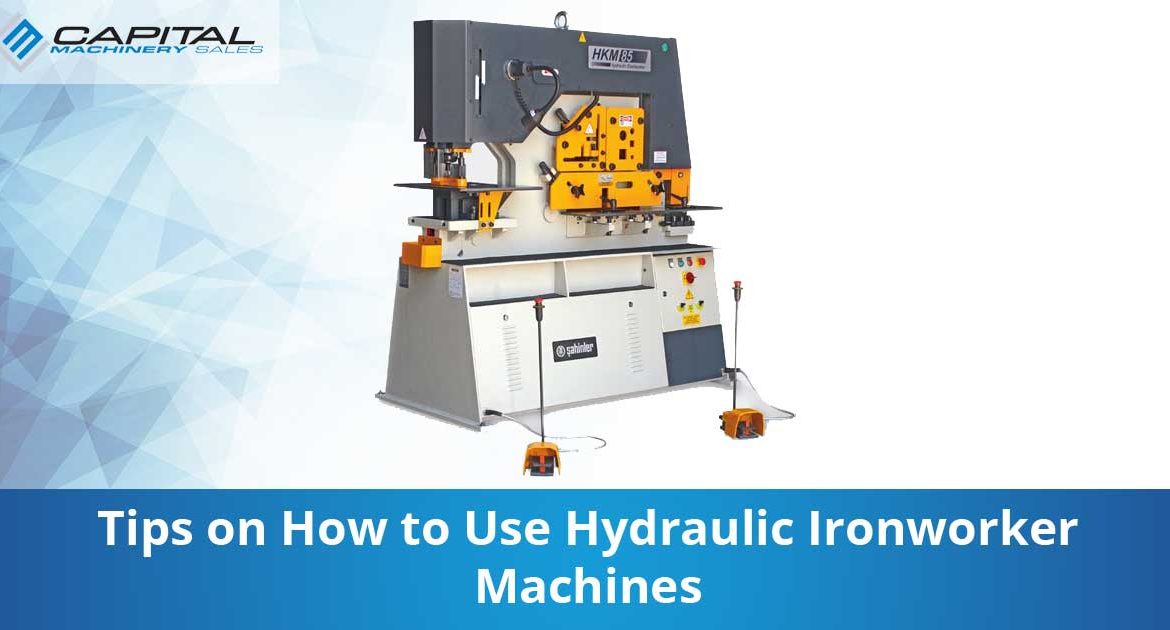

Tips on How to Use Hydraulic Ironworker Machines

Note that this is written for hydraulic ironworker machines and not to be mistaken for the mechanical operated machines although some of these procedures mentioned are practically the same.

Ironworker machines are often called as the “swiss army knife” of all machine tools because they are designed to punch, shear, bend and notch mild steel plates, angle iron, pipes, and barstocks. It has a wide range of accessories that are available to fabricate rod and square stock, pipe and metal sheet.

Though a lot of these machines have a pivot arm system that is being pulled down by a hydraulic cylinder, some of these ironworker machines operate by applying a hydraulic force to a moving centre plate. Its centre moves inside the machine frame in a simple, vertical path and exerts a downward force through its shear blades, punch dies, notchers, press brake dies or bump-die tooling to work with steel.

The vertical movement of the moving centre allows the operator to perform several operations without having to remove any adjacent tooling.

Now let us discuss some common sense safety precautions. To be able to use this hydraulic ironwork machine, you need to take heed on these safety precautions.

1. Make sure to read and understand the hydraulic ironworker machine operator manual, installation manual, machine safety and maintenance manual.

2. Make sure that the tool is being use only on its intended operation.

3. Always wear an approved eye protection.

4. Always wear appropriate protective clothing and gloves.

5. It is recommended that safety guards are used at all times, material hold-downs and punch stripper supplied with the Ironworker machine. Any removal modification or improper use of these safety devices can cause serious injuries and can cause your machine warranty to be voided.

6. Make sure that during its operation; keep any moving parts away to prevent any accidents or injuries or machine damage.

7. Always be prepared to lift your foot off the foot pedal.

8. Unplug or lock out your ironworker before starting any operations, maintenance or adjustments.

9. Maintenance, adjustments or changes in the tooling of your ironworker machine needs to be performed by a qualified individual as described in the process and procedures in the operator manual.

10. Always keep the machine clean. Any obstructions, slugs, cut-off pieces and fillings from the work area need to be cleaned.

11. Always turn your machine off when not in use or when you leave it unattended.