Used Swiftcut PRO 2500WT – CNC Plasma Cutting Table

- Brand: Capital Machinery Sales

Out of stock

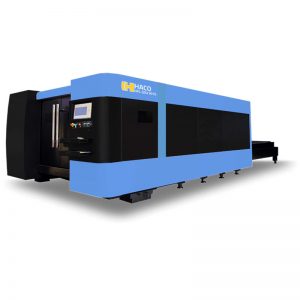

Used Swiftcut PRO 2500WT – CNC Plasma Cutting Table with a 2500 x 1250mm cutting area, the Swift-Cut PRO 2500 is a feature packed plasma cutting table and the ability and power to cut for long durations. Supplied with Hypertherm Powermax 105, a professional-grade plasma cutter that can cut up to 32 mm (1-1/4″) thick metal.

Used Swiftcut PRO 2500WT - CNC Plasma Cutting Table

Used Swiftcut PRO 2500WT - CNC Plasma Cutting Table

Description

Item Description

- SWIFTCUT MK4 2500WT CNC PLASMAP9023

- HYP PMX105 PLASMA 415V 3PH CPC

- HYP PMX 180 DEG TORCH 10.7M

- HYP ELIMINIZER FILTER 105/125

- HYP PMX105 WORK LEAD 7,6M

- SWITFTCUT 2500WT PRO 2020

- SWIFT CAM ADVANCED LICENCE

***OPTIONAL SOFTWARE UPGRADE WITH AUTONESTING AND QUTO LEAD IN – LEAD OUT*** - SWIFT MARK SCRIBE RETROFIT

*** OPTIONAL AIR POWERED ENGRAVING SCRIBE RETROFIT***

Overview

Used Swiftcut PRO 2500WT – CNC Plasma Cutting Table with a 2500 x 1250mm cutting area, the Swift-Cut PRO 2500 is a feature packed plasma cutting table and the ability and power to cut for long durations. With a robust steel fully welded frame and free standing operators console, making it ideal for workshops, metal fabricators, educational establishments, designers and artists.

With gantry parking to allow a full sheet to be loaded overhead and a dropped rail for ease of loading, not to mention the simple on-going maintenance, the Swift-Cut PRO 2500 really is the answer to all your cutting needs.

The Used Swiftcut PRO 2500WT – CNC Plasma Cutting Table supplied with Hypertherm Powermax 105.

This is a professional-grade plasma cutter that can cut up to 32 mm (1-1/4″) thick metal.

SOFTWARE: Standard Version

- Auto Arc voltage capture and regulation to automatically adjust the cut settings to suit varied material characteristics

- Program recovery function automates starting part way through a program

- Sheet Trim function to easily trim off excess skeleton

- G code browser & editor for the novice operator

- G code favourites – user customised

- DXF, DWG & JPEG photo import function

- 3D part Viewer

- Advanced importer with ability to re-export and save the filtered DXF

- 5 user assigned reference points for jigs and fixtures

- Sheet rotation function

- Automatic lead in / out of cut paths

- Dry run capability for testing prior to cutting

- Parametric shapes library with over 80 shapes

- Automatic cutting consumable recommendations based on material and thickness

- Manual nesting of parts

- Team viewer software for remote support

SOFTWARE: Advanced Version (Optional Extra)

- All of the Standard version features

- Automatic nesting parts for economical sheet usage

- Automatic Part in part nesting – Nests parts in scrap areas to fully utilise sheet

Features:

- Fully fabricated and welded steel frame

- Water tray for efficient control of sparks and fumes with removable stainless steel splash guards for side rail protection

- Dropped rails for ease of loading full sheets

- Gantry parking to allow full sheet to be loaded overhead

- Linear guideways for fast accurate motion

- High speed axis motors with closed loop feedback (encoder) for accuracy and reliability

- Dual motor drive Y-axis

- Rack and pinion drive system

- 360 Degree Breakaway head eliminates damage to torch and improves safety

- Laser guide for easy sheet positioning

- Free-Standing Operators Console with LCD TOUCHSCREEN control

- Cut metal up to 25mm thick depending on the Hypertherm Powermax unit selected

- Soft sense Digital Torch-Height Control (DTHC) Quick response for improved cut quantity and improved torch consumable life. This unique touch sensing is so soft and accurate even the thinnest sheet metal will not deflect while sensing.

- Dynamic Cut Control (DCC) is available on all Swiftcut PRO machines, This feature enables Software control of cutting amps and air pressure, Error messages, air pressures and critical data from the plasma unit is displayed on Swiftcut control screen for operator convenience, On the fly arc voltage, air pressure and cutting speed control ensures the highest quality cut at all times. INDUSTRY 1st UNIQUE TO SWIFT-CUT