Used 2022 FrameCAD F325iT-L Roll-Forming Machine

- Brand: Capital Machinery Sales

In stock

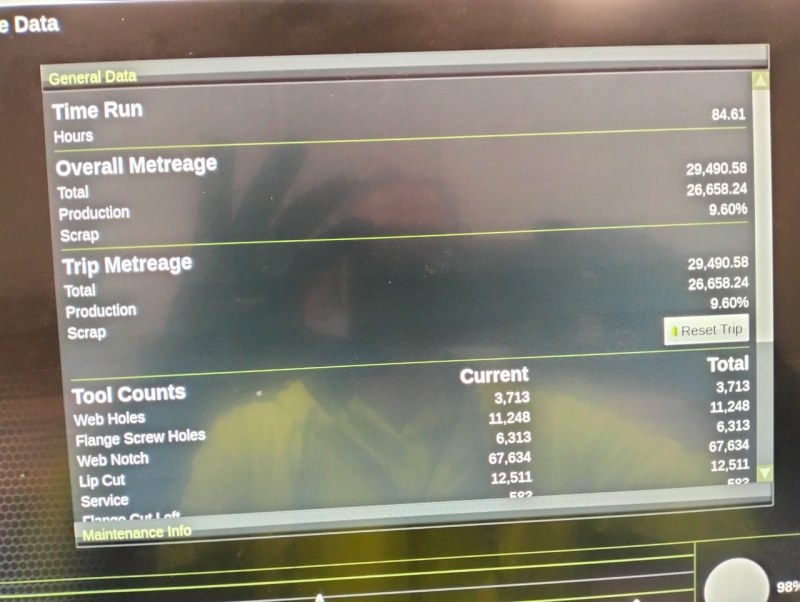

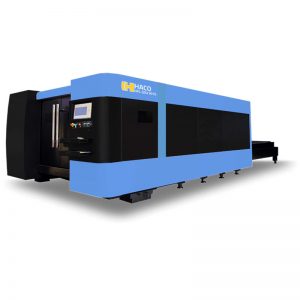

Used 2022 FRAMECAD F325iT-L Roll-Forming Machine – Only 84 operating hours – Fully serviced and supported. Complete system including setting out tables. Replace cost approximately $400,000 Designed for speed, efficiency, and versatility, it is the ultimate solution for modern construction needs. Experience the benefits of advanced technology, unparalleled support, and a smarter way to build. Transform your projects today and stay ahead of the curve with FRAMECAD.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Used 2022 FrameCAD F325iT-L Roll-Forming Machine

Used 2022 FrameCAD F325iT-L Roll-Forming Machine

Description

Used 2022 FRAMECAD F325iT-L Roll-Forming Machine – Only 84 operating hours – Fully serviced and supported. Complete system including setting out tables. Replace cost approximately $400,000 Designed for speed, efficiency, and versatility, it is the ultimate solution for modern construction needs. Experience the benefits of advanced technology, unparalleled support, and a smarter way to build. Transform your projects today and stay ahead of the curve with FRAMECAD.

FRAMECAD has developed highly efficient design and manufacturing technology for steel trusses and frames. The F325iT System is ideal for organizations aiming to achieve large-scale production and projects. It is fully optimized with patented technology for a streamlined production process. Advanced Computer Aided Engineering is utilized.

The FRAMECAD system connects with BIM Design software like REVIT and TEKLA. The intelligence in FRAMECAD Structure software allows for cost-effective design to enhance profitability and create strong buildings.

Features

- The F325iT efficiently produces wall frames, trusses, and joists for residential and light commercial buildings up to G+2.

- High line speed of up to 9,950 feet per hour (2,880 meters per hour) leads to the top framing and truss manufacturing output in the industry.

- 12 advanced hydraulic and punching functions for increased productivity and versatile component production, such as roof trusses, walls, and floor joists.

- An automatic gauging system that adjusts gauge range to enhance productivity for steel thickness of 24-18 gauge (0.55 – 1.2mm).

- Comes with a hydraulic cooling system designed for hot climates, perfect for high-temperature environments.

- Smart Internet connectivity offers cloud-based data reporting for real-time production management and technical diagnostics, enhancing efficiency.

Technical Specifications

| Model | F325iT-L |

| Profile Width (Web) | Range 63 – 150mm or 2⅟₂” – 6″ |

| Profile Height (Flange) | Range 34 – 50mm or 1⅟₃” – 2″ (Boxable Section reccommended) |

| Material Thickness | 0.55 – 1.2mm or 24 – 18 gauge |

| Roll Forming Stations | 13 Auto Gauging stations & 3 further forming stations |

| Punching Stations | 15 Frame and Truss Punching Stations (with the option of 5 more punching stations) |

| Standard Punch Tooling* | Service Hole, Web Bolt Hole, Dimple, Web Notch, Chamfer, Lip Cut, Flange Holes (left & right), Swage, Shear. (options to add Flange cut left and right plus additional web and flange punch tools)* |

| Max Line Speed | 2,880m/hr (9,950ft/hr) |

| Typical Production Speed (actual dependent on framing design) | Joists: 300 m/hr (985 ft/hr) Walls: 700 m/hr (2,300 ft/hr) |

| Main Drive Power | 7.5kW (10hp) |

| Hydraulic Power | 5.5kW (7.4hp) |

| Length | 4,000mm (13.12′) |

| Width | 800mm (2.65′) |

| Height – to top of covers | 1200mm (3.95′) |

| Weight (approx.) | 1,970kg (4,343lb) |

| Printer | 2 Printer Heads |

| Decoiler Capacity | 3,000kg (6,600lb) powered Decoiler |

Additional information

Additional information

| Weight | 900 kg |

|---|---|

| Shipping Weight | 1970 kg |