Unitech UB38 Pipe & Tube Rotary Draw Bender Machine with NC Controller

- Brand: Unitech Industrial

In stock

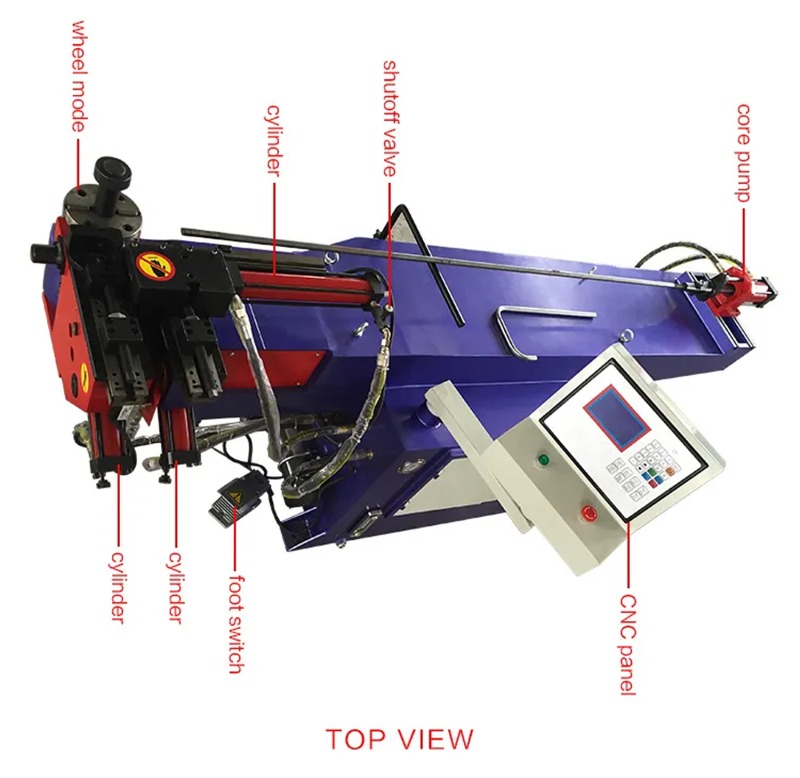

The Unitech UB38 Pipe & Tube Rotary Draw Bender Machine with NC Controller NC pipe bending machines are designed as alternatives to CNC pipe bending machines with a lower cost than CNC models. It will help you to reach your target in the most economical way on pipe and tube bending works. It uses a single-chip NC unit to control the running.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Unitech UB38 Pipe & Tube Rotary Draw Bender Machine with NC Controller

Unitech UB38 Pipe & Tube Rotary Draw Bender Machine with NC Controller

Description

The Unitech UB38 Pipe & Tube Rotary Draw Bending Machine with NC Controller NC pipe bending machines are designed as alternatives to CNC pipe bending machines with a lower cost than CNC models. It will help you to reach your target in the most economical way on pipe and tube bending works. It uses a single-chip NC unit to control the running. The feeding and rotation are positioned by manual, the bending is controlled by a hydraulic cylinder. Suitable to bend simple bend parts or simple multi-plane parts with medium volume. We can use it for bending various materials such as stainless steel, aluminum, copper, carbon steel, etc.

Features:

- Integrated body, welded with high-strength steel plate, sturdy structure, providing maximum operating space.

- Equipped with the single-chip microcomputer NC control system, English display on screen, easy and convenient operation, flexible setting

- With manual control, half-cycle control, full automatic control and other functions, overload automatic protection.

- Hydraulic cylinder control bending, clamping and auxiliary pushing and mandrel extraction

- The bending arm adopts imported silent high-intensity rack and pinion transmission, powerful and stable

- The throttle valve is installed on the main cylinder of the bending arm to control the flow to adjust the bending speed.

- The bending angle is controlled by an encoder, with an accuracy of ±0.15°

- Mandrel bend and non-mandrel bend can be set as required;

- Automatically detect machine failures and operation failures.

- It can store multiple sets of processing modes, and flexibly switch between programs of different specifications.

- It can count automatically, with automatic protection function in case of power failure, and data can be saved.

- Water cooling system, quickly cool down, ensure the equipment to work stably under high temperature for a long time

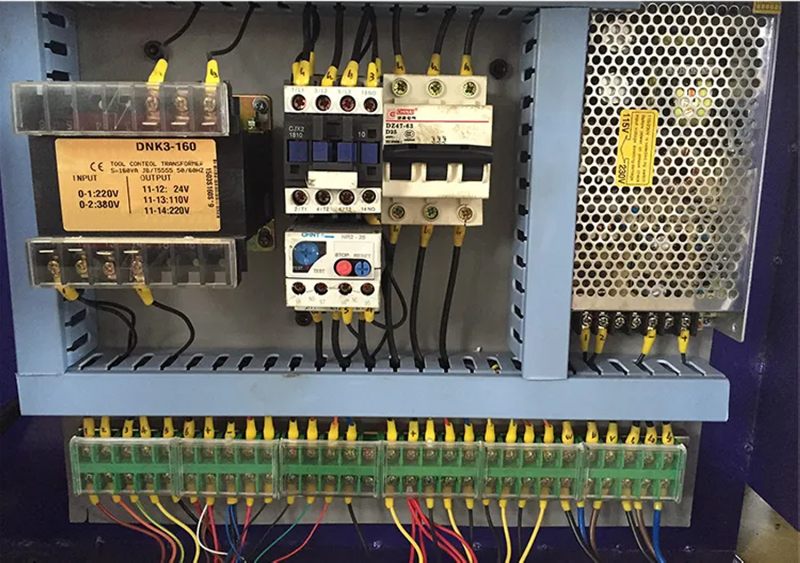

- Electrical components adopt Schneider of France, strong performance, good stability, and long service life

- Mobile footswitch with start and emergency stop functions for more protection

Product samples:

Subverting tradition, multi ends.

Product Features:

The main features of our products have always touched you a little.

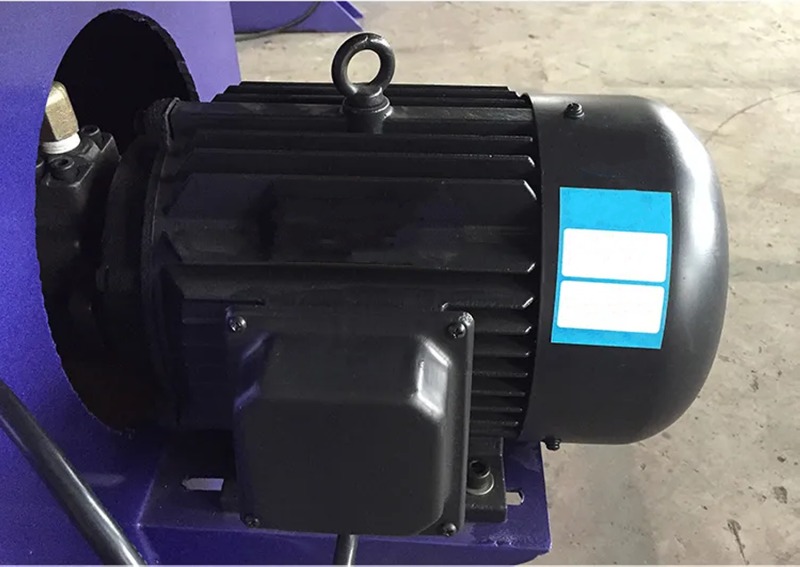

Cylinder Motor

The drive oil pump supplies to the whole machine, and the whole copper core motor has more stable performance.

Electrical System

Control the power supply of the whole machine and adopt high-end brands such as Schneider to make the machine more durable.

Core Pump

The control tube is not deformed during the bending process.

Hydraulic elbow

Elbow drive mode: hydraulic drive gear rack elbow, the transmission is more powerful and stable.

Angle control wheel

With the Japanese internal control encoder, the performance is more stable and the bending fullness is improved.

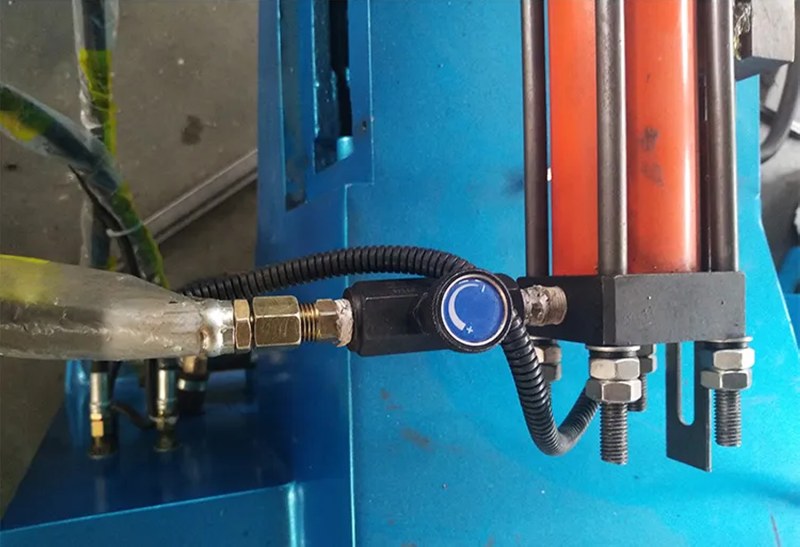

Shutoff Valve

Adjust the cylinder pressure and control the flow to adjust the working speed

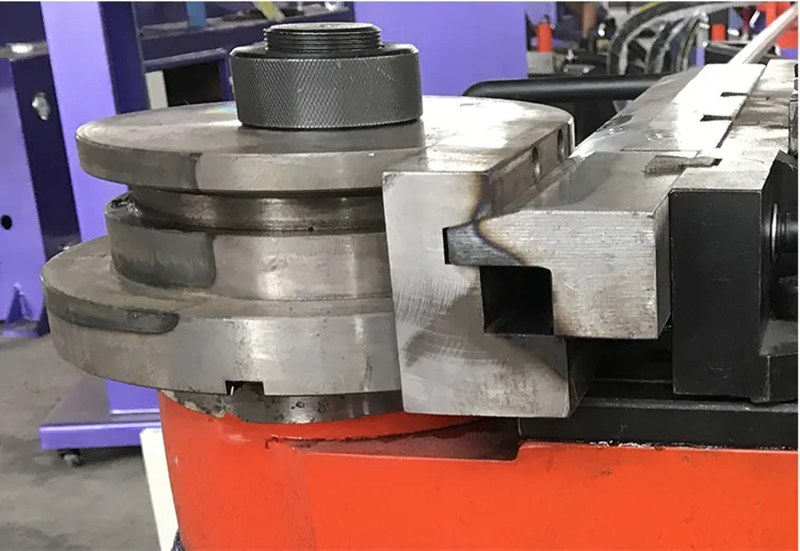

Bending former dies

The Bending former dies can be customized according to different processing pipe fittings.

Shop Exhibition

Specialized workshop, this is our strength

Specifications

| Material / Metal Processed: | ALLOY, Brass / Copper, Carbon steel, Stainless steel, PVC, Aluminum |

| Max. Bending Angle (Deg): | 190 |

| Bending Precision (Deg): | 1 |

| Automation: | Semi-automatic |

| Power (kW): | 4 |

| Weight (KG): | 700 |

| Warranty: | 1 Year |

| Key Selling Points: | High Productivity |

| Warranty of core components: | 1 Year |

| Core Components: | Bearing, Motor, Pump, Gear, PLC, Engine, Gearbox |

| Maximum use of carbon steel pipe: | 38*2.0mm |

| Maximum use of stainless steel pipe: | 32*1.5mm |

| Maximum square iron tube: | 25*25*2.0 |

| Maximum bending radius: | 200mm |

| Maximum bending angle: | 190° |

| Maximum core length: | 1700mm |

| The Number of bends per tube: | 16 |

| Motor power: | 4KW |

| Maximum oil pressure: | 12 mpa |

| Hydraulic control system: | Solenoid valve |

Unitech UB38 Pipe & Tube Rotary Draw Bending Machine with NC Controller Video

Specification

Additional information

| Weight | 700 kg |

|---|---|

| Kilowatt (kW) |

Reviews

- 3d tube bending machine

- ylm tube bending machine

- pipe tube bending machine

- metal tube bending machine

- tube bending machine price

- tube bending machine video

- copper tube bending machine

- tube bending machine manual

- unison tube bending machine

- mandrel tube bending machine

- bending tube machine bunnings

- electric tube bending machine

- mandrill tube bending machine

- tube and pipe bending machine

- tube bending machine for sale

- aluminium tube bending machine

- automatic tube bending machine

- cnc tube bending machine price

- hydraulic tube bending machine

- serpentine tube bending machine

- rectangular tube bending machine

- second hand tube bending machine

- tube bending machine manufacturers

- square tube bending machine for sale

- stainless steel tube bending machine

- cnc tube bending machine manufacturers

- cnc electric tube bender

- cnc laser tube cutting machine

- cnc mandrel tube bender for sale

- cnc plasma rotary tube cutters

- cnc plasma tube cutter

- cnc tube bender for sale

- cnc tube bending and notching

- cnc tube bending brisbane

- cnc tube bending company

- cnc tube bending machine

- cnc tube bending melbourne

- cnc tube bending near me

- cnc tube bending service

- cnc tube bending uk

- cnc tube cutting machine

- cnc tube cutting software

- cnc tube laser cutter

- diy cnc tube bender