SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine

Introducing the SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine your ideal solution for precise and efficient pipe preparation. Effortlessly cut through materials ranging from carbon steel to stainless steel, achieving flawless bevels ready for welding. This machine combines cost-effectiveness with reliable performance, enabling you to deliver quality results while managing expenses effectively.

SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine

SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine

Description

Introducing the SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine, an optimal solution for precise and efficient pipe preparation. It seamlessly cuts materials from carbon steel to stainless steel, achieving impeccable bevels ready for welding. This machine offers a balance of cost-effectiveness and reliable performance, allowing you to deliver high-quality results while efficiently managing expenses.

Features:

- Simultaneously cut and bevel pipes to achieve a clean, precision-prepped edge with every cut. Eliminate the need for tool switching or reworking, delivering seamless, ready-to-weld pipes.

- Cold cutting for diverse materials: Efficiently bevel without compromising pipe integrity, suitable for carbon steel, stainless steel, or low-temperature steel.

- Adjustable for various pipe sizes: Engineered to adapt to different pipe diameters, ensuring perfect cuts and bevels regardless of size.

- Self-centering concentric clamping: Multi-jaws securely and concentrically hold pipes, including thin-walled steel, without deformation, accommodating the flexibility of thin-walled pipes.

- High processing efficiency: Enhance productivity and minimize downtime by achieving more in less time.

| Pipe SIze | Time Take |

| 4” x 6mm | 2 min |

| 8” x 10mm | 4 min |

| 12” x 12mm | 5 min |

Notes

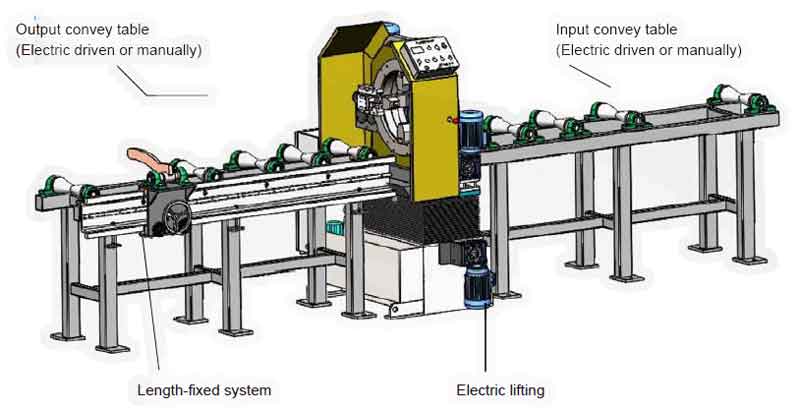

- To avoid equipment or tool damage from pipe clamping eccentricity, it is important to ensure proper pipe support.

- Aligning the pipe center with the machine center is vital to maintain a vertical pipe end face.

- A conveyor roller table is ideal for this purpose.

- Moreover, for accurate pipe length positioning, we provide an optional fixed length mechanism.

SMG Orbi-Edge 426W Workshop Pipe Cutting and Beveling Machine Layout

Optional Equipment

- Equipment Entry Conveyer Table

- Driven: Electric

- 3M Length complete with PU or steel Rollers

Output Conveyer Table with Fixed-Length Mechanism

-

- Driven: Manually

- 3M Length complete with PU or Steel Rollers

Technical Specification

| Model | SMG-426W |

| Working Range | 3″-16″ 89-426mm |

| Rotation Speed | 0-35 Adjustable |

| Power (Kw) | 5.5 |

| Center height of Equipment(mm) | 940-1100 |

| Weight (Kgs) | 1200 |

| Clamping Mode | 4 jaws Electric |

| Lifting | Electric |

| Beveling Material |

Kinds of Stainless Steel, Alloy steel, Carbon steel

|

| Wall thickness |

S.S.: 3-25mm. C.S.:3-30mm (Special tool box and tool up to 45mm)

|

| Number of Tool | 2 |

| Type of Beveling |

Comply with ASME B16.25, U, V, X

|

| Beveling Angle | 30 / 37.5 or as per requirement |

| Tool Feed | Radial feed, automatically |

| Feed Rate | 0.1-0.2mm/r |

| Cutting tips | HSS |

| Cooling system | Circulating water cooling |

| Machining accuracy | Roughness:<Ra12.5 Perpendicularity: <1mm Angular deviation:<0.5º |

| Power supply | 415V 3PH 50/60HZ |