SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm)

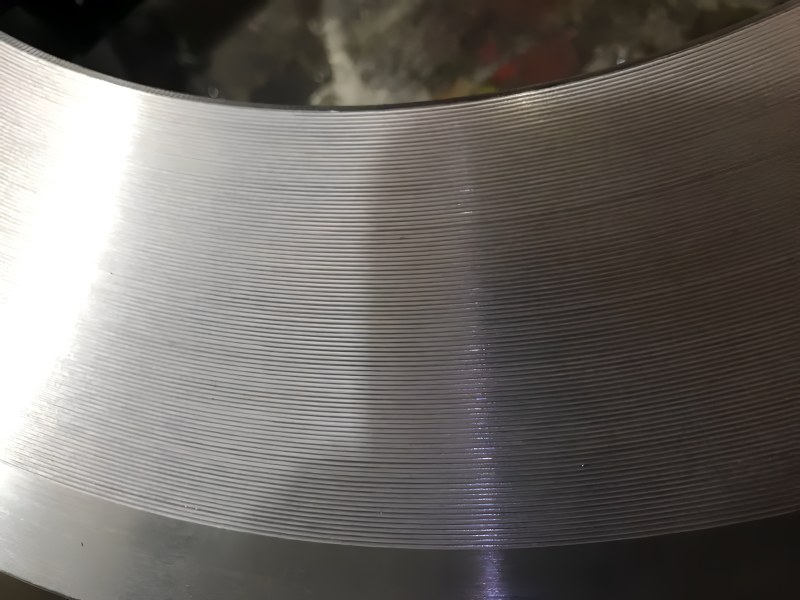

The SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm) is an overall cost effective technique which allows you to face, bevel, and turn pipe, value and pump flange with ease . Which in turn helps to keep your plant running efficiently, safely and more environmentally friendly. It gives machine shop accuracy , combined with ease of handing and portability in the flange range .Spur gears engage directly on the drive ring, keep power requirements and losses to a minimum and allowing maximum torque at the cutting tool . When the machine is used in the vertical plane , balancing is greatly reduced. F610 can be used in horizontally, vertically or overhead planes.

SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm)

SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm)

Description

The SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm) is an overall cost effective technique which allows you to face, bevel, and turn pipe, value and pump flange with ease . Which in turn helps to keep your plant running efficiently, safely and more environmentally friendly. It gives machine shop accuracy , combined with ease of handing and portability in the flange range .Spur gears engage directly on the drive ring, keep power requirements and losses to a minimum and allowing maximum torque at the cutting tool . When the machine is used in the vertical plane , balancing is greatly reduced. F610 can be used in horizontally, vertically or overhead planes.

Specification

| Technical Details | ||

| Facing Diameter: | ||

| Min Facing Diameter | 2.0 inches | 50 mm |

| Max Facing Diameter | 24.0 inches | 609.6 mm |

| ID Mounting Diameter | ||

| Min I.D. Mount | 2.0 inches | 50 mm |

| Max I.D. Mount | 22 inches | 558 mm |

| Stroke: | ||

| Tool Feed Stroke | 2.0 inches | 50 mm |

| Tool Post Swivel Angle | + / – 30⁰ | |

| R.P.M | Min:0 | Max:42 |

| Drive-Pneumatic @ 90 P.S.I (6 bar) Servo motor system Electric motor | 0.89 KW 0.75 KW 1.3 KW | 1.2 HP 1.0 HP 1.75 HP |

| Air Consumption / Supply Required | 42 S.C.F.M | 1.2 m³/min |

| Approximately Operational Weight | 99 lbs | 45 kg |

| Approximately Shipping Weight | 136 lbs | 72 kg |

| Approximately Shipping Dimensions Length x Width x Height | 26 x 18 x 16 inches | 670 x 450 x 400 mm |

| Facing Feed Rates | ||||

| inches/rev | mm/rev | Grooves per inches | Grooves per mm | |

| 1.00mm Pitch Lead Screw (optional) | ||||

| Fine | 0.004 | 0.114 | 224 | 880 |

| Coarse | 0.018 | 0.455 | 56 | 220 |

| 1.25mm Pitch Lead Screw (standard) | ||||

| Fine | 0.006 | 0.142 | 179 | 700 |

| Coarse | 0.022 | 0.568 | 45 | 180 |

| 1.75mm Pitch Lead Screw (standard) | ||||

| Fine | 0.008 | 0.199 | 128 | 500 |

| Coarse | 0.031 | 0.795 | 32 | 130 |

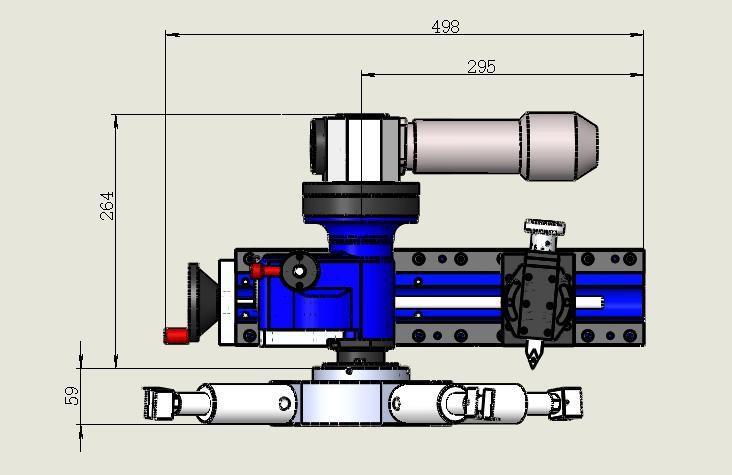

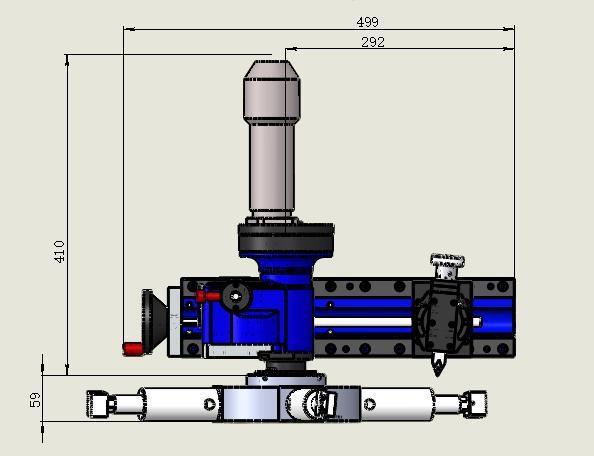

Operational Dimensions

Quick and Easy Setup & Removal

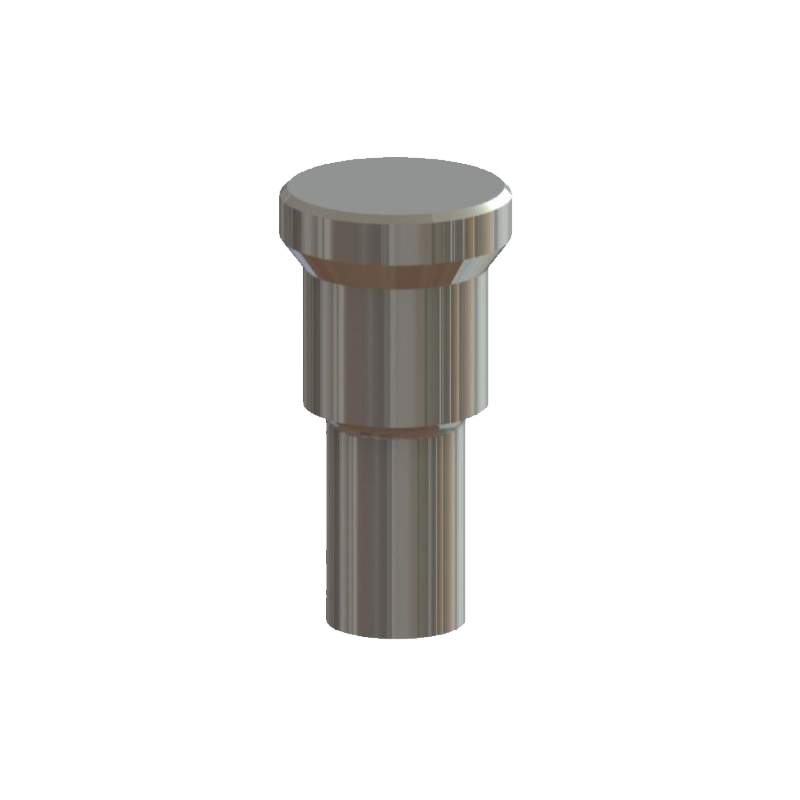

- Separate mounting chuck.

- All centering and leveling is done on the chuck.

Lightweight

- Body of machine weighs only 99 lbs (45 kg).

- Smallest mounting chuck weighs about 5 lbs (2.2 kg).

Safe and Quiet Operation

- Stationary feed rate selector.

- Machine is controlled without touching any moving parts.

- Exhaust air is routed through body of machine for increased muffling.

Simplified Operation

- Single selector switch for bidirectional radial feed or vertical downfeed.

- One wrench size for clamping jaws and body draw bolt.

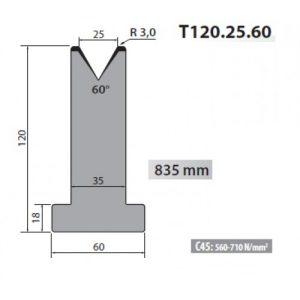

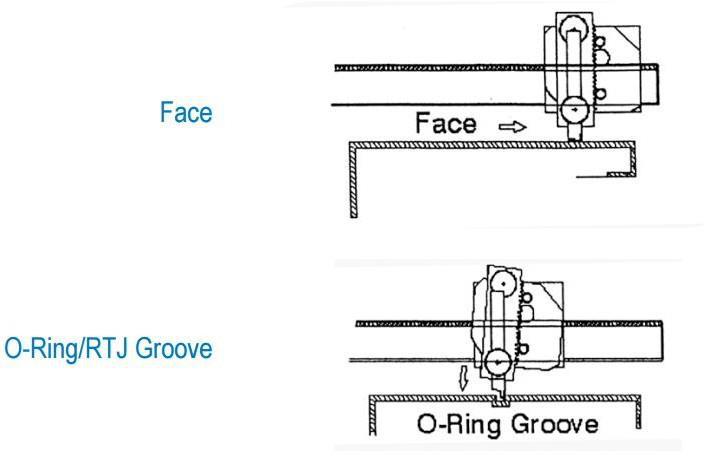

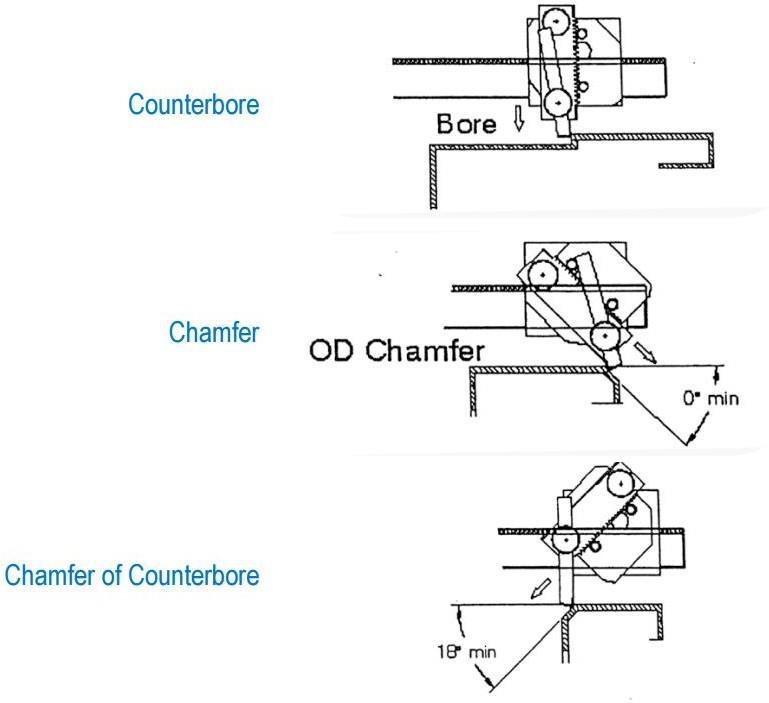

Cuts Chamfers and Grooves

- Compound tool head and downfeed for cutting angles and grooves.

The SMG F610 Pneumatic Flange Facing Machine (Facing Range: 2 – 24” (50 – 610mm) machine is supplied complete with toolkit including tools and inserts, air filter lubricator and hose connection, all required mounting base and extensions, storage / shipping box, CE certificate, packing list and manual.

F610 Packing picture

Dimension & weight:67 x 45 x 40 cm,Wooden:72kg , /Steel package,85kg.

SMG F610 Flange Facing Machine Packing List

| Item | Product Name | Quantity | Unit |

| 1 | Primary machine | 1 | SET |

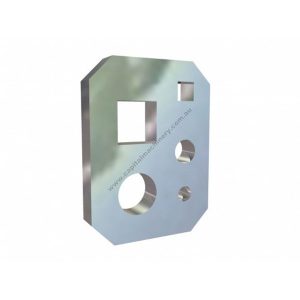

| 2 | Base support | 3 | SET |

| 3 | Pneumatic motor | 1 | SET |

| 4 | Mounting block | 4 | PCS |

| 5 | Lead screw | 3 | Unit |

| 6 | Mounting leg | 12 | PCS |

| 7 | Counterweight block | 1 | PC |

| 8 | Counterweight plate | 1 | PC |

| 9 | Balance bar | 4 | PCS |

| 10 | Gasket | 1 | PC |

| 11 | Arm bolt | 4 | PCS |

| 12 | Air filter | 1 | SET |

| 13 | Air Hose | 1 | PC |

| 14 | Cutter head | 6 | PCS |

| 15 | Cutters | 3 | PCS |

| 16 | Allen wrench tools | 3 | SET |

| 17 | Hex socket | 2 | PCS |

| 18 | RTJ grooving tools | 1 | SET |

| 19 | HSS Tool | 1 | PC |

| 20 | Operation Manual | 1 | UNIT |

| 21 | Wooden package/Optional Steel package | 1 | UNIT |

APPLICATIONS

SMG F610 ON SITE MACHINE TOOLS

Flange facing machine application for Oil, Gas and Chemical ,Power Generation ,Heavy Equipment ,Ship building & repair

Typical applications:

- Piping system flanges

- Valve flanges and bonnet flanges

- Heat exchanger flanges

- Vessel flanges

- Flange faces on piping systems

- Pump housing flanges

- Weld preps

- Tube sheet bundles.

- Bearing mounting bases

- Final drive hubs

- Bull gear faces

- Manufacturing of mining equipment

- Slew rings

- Bearing mounting bases

- Crane pedestal flange.

- flange facer

- flange facing head

- flange facing tool

- flange facing lathe

- flange facing system

- flange facing machine

- flange facing service

- flange facing standard

- flange facing equipment

- flange facing operation

- flange refacing machine

- cnc flange facing machine

- pipe flange facing machine

- flange facing machine parts

- flange facing machine price

- flange facing machine types

- flange facing machine video

- flange facing machine market

- flange facing machine rental

- flange facing machine repair

- mirage flange facing machine

- flange facing machine for sale

- flange facing machine industry

- flange facing machine training

- portable flange facing machine

- flange facing machine suppliers

- hydraulic flange facing machine

- flange facing machine application

- flange facing machine maintenance

- flange facing operation procedure

- flange facing machine manufacturer

- flange facing machine specification

- portable flange facing machine supplier