SMG 3000XA NC Three in One Busbar Processing Station

- Brand: Steel Machinery Group

In stock

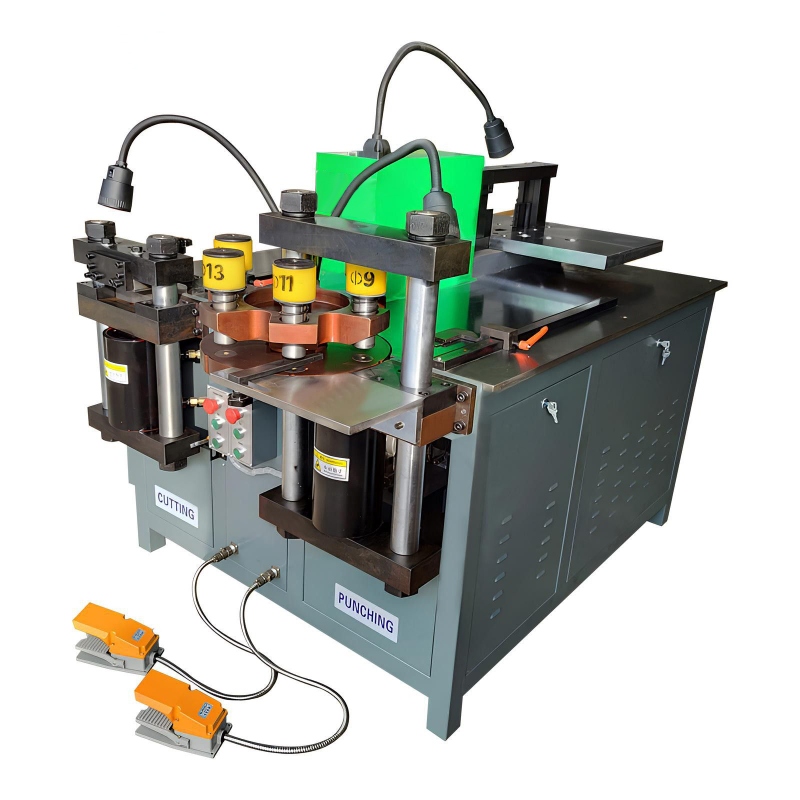

The SMG 3000XA NC Three in One Busbar Processing Station is designed to perform punching, shearing, and bending as well as many other supposed operations required to complete your processing needs.

The cleaver design allows set-up flexibility streamlining the processing both boosting production efficiency and reducing handling time significantly. The bending unit is equipped with a quality PLC control system ensuring precision and stability when processing copper and aluminium busbars of varying specifications.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

SMG 3000XA NC Three in One Busbar Processing Station

SMG 3000XA NC Three in One Busbar Processing Station

Description

Elevate your busbar processing with the SMG-3000XA NC Three In One Busbar Processing Station. Designed to enhance metal fabrication, this machine combines cutting, punching, and bending into a single, efficient workflow. It uses three separate hydraulic power packs to deliver exceptional performance.

Features

CUT–Double column shear structure

The shearing station has a strong double column structure for stability and precision. Each cut is clean and smooth, without scrap, burrs, or collapse.

PUNCH—a unified six-mode turnplate featuring a tooth-shaped design.

Design to enhance punch die alignment, extending their lifespan and reducing the need for frequent replacements. Utilize three precise positioning methods—coordinate axis positioning, a punch positioning pin, and a central laser pointer—to accurately locate hole centers for perfect punching.

BEND — Controlled by a SIEMENS system

Controlled by an advanced SIEMENS system, the bending station provides high accuracy and can perform various bends like vertical, horizontal, U-shaped, Z-shaped, twisted, and embossing. Just input your data, and the machine completes your complex bending tasks with precision.

Technical Specifications:

|

Punching |

Max Punching Force (kn) | 300kn |

| Punching dia. range (mm) | Ø 4.3 – Ø 25 mm | |

| Max. thickness (mm) | 12mm | |

| Max. width (mm) | 160mm | |

|

Shearing / Cutting |

Max. shearing thickness (mm | 12mm |

| Max. shearing width (mm) | 160mm | |

| Vertical Bending | Max. Bending Force (KN) | 300mm |

| Max. Thickness (MM) | 12mm | |

| Max. Width (MM) | 160mm | |

|

Horizontal Bending |

Max. Width (MM) | 120×10 |

| Max. Angle (Degree) | 90° | |

|

Twist Bending |

Max. Thickness (MM) | 12mm |

| Max. Width (MM) | 160mm | |

| Outer Dimension | 1950x1560x1420mm | |

| Power | 3 x 4.0kw | |

| Weight | 1400kg | |

|

CNC Precision |

Bending Precision | ±1° |

| Repeat Bending Precision | ±0.3° | |

Standard Accessories:

|

Punching Dies Available Tooling Size: Round hole of punching die: Φ7, Φ9, Φ11, Φ13, Φ15, Φ17, Φ19, Φ21 (mm) Oval hole of punching die: 7×11 (mm), 9×13 (mm), 11×15 (mm), 13×18 (mm), 17×21 (mm) Customized Punching Tooling also available |

8 sets |

|

Cutting Blade |

2 sets |

|

Horizontal bending dies |

2 sets |

|

Vertical bending dies |

2 sets |

|

U shape bending die |

1 set |

|

Oil filler |

1 set |

|

Inner hexagon spanner |

1 set |

|

Hydraulic system sealing ring |

1 set |

|

Foot switches |

3 sets |

|

Limit switches |

2 pieces |

|

Punching location needle |

1 piece |

|

Magnetic location block |

1 set |

|

Embossing Molds |

1 set |

Additional information

Additional information

| Weight | 900 kg |

|---|---|

| Dimensions | 195 × 156 × 142 cm |

| Shipping Weight | 1400 kg |

Reviews

- Busbar slotting machine

- Busbar drilling machine

- Busbar punching and shearing machine

- Busbar processing center

- Busbar production machinery

- Busbar marking machine

- busbar punching machine

- Hydraulic busbar machine

- Busbar bending and punching machine

- Busbar cutting machine

- Busbar shearing machine

- Busbar manufacturing equipment

- Busbar leveling machine

- copper busbar punching machine

- Multi-station busbar machine

- Copper busbar machine

- Busbar processing machine

- Busbar end milling machine

- Busbar fabrication machine

- Busbar fabrication line

- Busbar bending machine

- 3 in 1 busbar machine

- Automatic busbar machine

- Busbar automation equipment

- Busbar assembly machine

- Busbar handling system

- Portable busbar machine

- Busbar wrapping machine

- Busbar inspection machine

- novopress busbar bending machine

- CNC busbar machine

- copper busbar beding machine

- copper busbar bending machine

- Busbar chamfering machine

- Busbar crimping machine

- Busbar trunking machine

- guillotine metal cutter

- sheet metal guillotines

- hydraulic guillotine for sale

- hand guillotine shear

- hydraulic guillotine shear machine

- hydraulic metal guillotine

- hydraulic stone guillotine for sale

- manual sheet metal guillotine

- hydraulic guillotine

- metal master guillotine

- hydraulic guillotine machine

- acra shear guillotine

- hydraulic guillotine cutter

- sheet metal guillotine blades

- busbar cutting machine

- hydraulic swing beam shear guillotine

- what is a guillotine used for in metalwork

- busbar cutting punching and bending machine

- copper busbar cutting machine

- hydraulic guillotine manufacturers

- hydraulic guillotine shears

- hydraulic sheet metal guillotine

- hydraulic swing beam sheer guillotine

- hydraulic busbar metal guillotine shear adjustable

- hydraulic busbar metal guillotine shear alignment

- hydraulic busbar metal guillotine shear angle

- hydraulic busbar metal guillotine shear attachment

- hydraulic busbar metal guillotine shear bender

- hydraulic busbar metal guillotine shear blade

- hydraulic busbar metal guillotine shear box

- hydraulic busbar metal guillotine shear capacity australia

- hydraulic busbar metal guillotine shear chart

- hydraulic busbar metal guillotine shear clamp

- hydraulic busbar metal guillotine shear clip

- hydraulic busbar metal guillotine shear design

- hydraulic busbar metal guillotine shear dimensions

- hydraulic busbar metal guillotine shear effect

- hydraulic busbar metal guillotine shear efficiency

- hydraulic busbar metal guillotine shear end

- hydraulic busbar metal guillotine shear enhancer

- hydraulic busbar metal guillotine shear force diagram

- hydraulic busbar metal guillotine shear grinder

- hydraulic busbar metal guillotine shear grip

- hydraulic busbar metal guillotine shear guide

- hydraulic busbar metal guillotine shear hammer

- hydraulic busbar metal guillotine shear handle

- hydraulic busbar metal guillotine shear height

- hydraulic busbar metal guillotine shear impact

- hydraulic busbar metal guillotine shear impeller

- hydraulic busbar metal guillotine shear in australia

- hydraulic busbar metal guillotine shear in sydney

- hydraulic busbar metal guillotine shear key

- hydraulic busbar metal guillotine shear length

- hydraulic busbar metal guillotine shear link

- hydraulic busbar metal guillotine shear loader

- hydraulic busbar metal guillotine shear machine

- hydraulic busbar metal guillotine shear model

- hydraulic busbar metal guillotine shear overflow

- hydraulic busbar metal guillotine shear plate

- hydraulic busbar metal guillotine shear price

- hydraulic busbar metal guillotine shear qualification

- hydraulic busbar metal guillotine shear quick release

- hydraulic busbar metal guillotine shear rate

- hydraulic busbar metal guillotine shear reinforcement

- hydraulic busbar metal guillotine shear resistance

- hydraulic busbar metal guillotine shear strength

- hydraulic busbar metal guillotine shear tension

- hydraulic busbar metal guillotine shear type

- hydraulic busbar metal guillotine shear unit

- hydraulic busbar metal guillotine shear value australia

- hydraulic busbar metal guillotine shear velocity

- hydraulic busbar metal guillotine shear weight