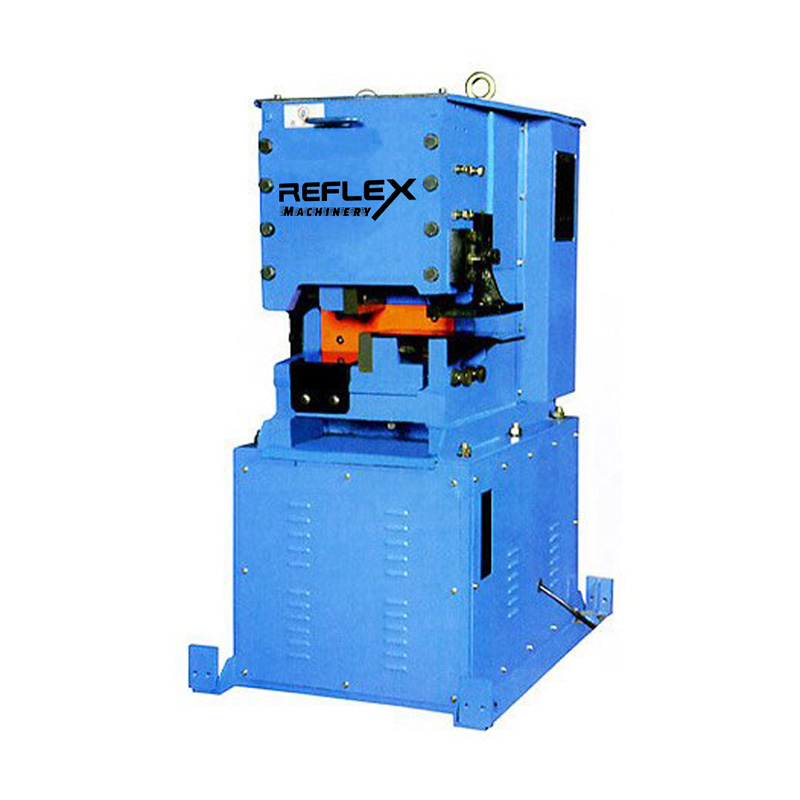

Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine

- Brand: Reflex

In stock

The Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine emerges as a beacon of innovation, designed to transform the way professionals approach rebar processing. Experience an unprecedented blend of durability, efficiency, and cost-effectiveness with a machine that’s engineered to exceed expectations. Features Rated Power: 8kW | Rebar Diameter: Ø 5-12mm | Speed: 20m/min | Cut Length Error: ±10mm | Bend Round Lead: 0-60mm | Lead Error: ±10mm | Sizes: Ø5-6: 90-1000mm, Ø8-12: 120-1000mm. Explore the optimal rebar processing solution offering high power, precise cutting, and versatile sizing options.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine

Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine

Description

The Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine emerges as a beacon of innovation, designed to transform the way professionals approach rebar processing. Experience an unprecedented blend of durability, efficiency, and cost-effectiveness with a machine that’s engineered to exceed expectations.

Features:

- Innovative Built-in Feeding Mechanism: The GX512 is crafted with an automatic feeding system, ensuring high dimensional accuracy and streamlining the spiral-making process. This feature not only saves time but also significantly reduces manual labor, setting a new standard for convenience and efficiency.

- Special Steel Alloy Components: The heart of this machine lies in its straightening, driving, and measuring rollers, which are made from a special steel alloy. This choice of material guarantees high wear resistance, extending the machine’s service life and ensuring long-term cost savings.

- User-Friendly Operator Control Panel: Designed with the operator in mind, the GX512 features a convenient and intuitive control panel. This simplifies machine operation, allowing for quick adjustments and smoother project workflows.

- Energy-Efficient Performance: With low power consumption, this machine stands as an eco-friendly solution to rebar processing. Reduce your project’s carbon footprint without compromising efficiency.

- Advanced Cutting and Bending: Equipped with a prefabricated multifunctional knife mechanism and 3 bending rollers, the GX512 achieves steel spirals with diameters ranging from 90-1000 mm. Paired with a hydraulic cut, it ensures stable and reliable operation across a broad range of projects.

- Robust Design with Advanced Gearbox: Its simple yet reliable design is supported by a worm gearbox connected to a servo drive, augmented by dual electric motors. This configuration not only enhances the drawing of reinforcement but also promises unparalleled durability and a prolonged service life.

Benefits:

Using the Reflex Fast Form GX512 not only streamlines your construction projects but also offers a multitude of advantages, including:

- Automatic Feeding Mechanism: Maximizes productivity while minimizing manual intervention, leading to faster project completion times.

- High Wear Resistance: Reduces the need for frequent replacements and maintenance, ensuring that your machine remains operational for longer periods.

- Exceptional Precision: Delivers products with high dimensional accuracy, enhancing the overall quality of construction.

- Cost-Effective: The special design and materials used in the GX512 minimize raw material wastage and operational costs, boosting profitability.

The Reflex Fast Form GX512 Rebar Spiral/Spiraling Machine is not just a piece of equipment; it’s an essential partner in your construction endeavors, designed to meet the rigorous demands of modern projects. Elevate your productivity and achieve superior results with a machine that’s built to last.

Pre-installation guidelines and technical prerequisites for preparing the production site to commence the installation of the straightening equipment.

Ambient temperature should range from 0 to +40 °C.

- Humidity levels must not exceed 80% at a temperature of +25 °C.

- Position the equipment at a minimum distance of 1.2 meters from walls, columns, and heating registers.

- Ensure a level, dry, and clean surface with a height variance of no more than 50mm compared to the chosen base.

- A 380V power supply with a switch suited to the machine’s power, exceeding 20%, is required.

- If voltage decreases by over 10% of the nominal value, purchasing a voltage stabilizer based on the total power source capacity is necessary.

- Secure the machine to the floor using an anchoring method. If concealed utilities are present, a schematic of these utilities is needed.

Equipment needed for installation:

- Industrial hammer drill with a 15mm drill diameter

- 4 anchors (15mm diameter)

- Angle grinder with cutting and grinding wheel

- Construction level measuring at least 1m

- Bolt cutter (up to 16mm)

- Sledgehammer

- Crowbar and nail puller

- 5-10 meters tape measure

- Chalk

Equipment needed for installation:

- Truck crane matching the equipment’s weight, or

- Forklift with appropriate lifting capacity, or

- Crane beam suitable for the installed equipment.

Reflex Fast Form GX512 Rebar Spiral Machine – Perfect for:

- Tunnel Segment Applications

- Steel Pile Cage Wire Usage

Diagram Illustrating Equipment Layout

Examples of Spiral Steel Rods

Coil holder (included)

- Capable of supporting up to 5 tons

- Equipped with an optional automatic air brake system

- Easily disassembled for convenient transport

Technical Specification:

| Model | GX512 |

| Dimensions, L×W×H | 2000 × 850 × 1500 mm |

| Cutting Length Processing Accuracy | ±10 |

| Step Processing Accuracy | ±10 mm |

| Reinforcement Class | A400 (A-III)/A400C/A500/A500C |

| Tensile Strength | 590 / 600 N/mm2 |

| Yield Strength | 390 / 500 N/mm2 |

| Rod Diameter | 5-12 / 5-10 mm |

| Control | Automatic |

| Diameter Of Circular Bending Part | 90-1000 (at ⌀ 5-6) / 120-1000 (at ⌀ 8-12) mm |

| Maximum Broaching Speed, | 20 m/mm |

| Circular Bending Pitch | 0-60 mm |

| Bending Direction | One direction |

| Rated Power | 8 kW |

| Temperature Range For Normal Operation | =+5…+40 °C |

| Electrical Network Voltage | 380 V |

| AC Frequency | 50 Hz |

| Average Electricity Consumption | 8 kW/h |

| Certification | ISO 9001:2008 |

| Weight | 650 kg |

| Gross Weight | 815 kg |

Specification

Additional information

| Weight | 650 kg |

|---|---|

| Dimensions | 200 × 85 × 150 cm |

Reviews

- spiral bound machine

- spiral machine price

- spiral mixer machine

- spiral punch machine

- spiral making machine

- spiral bending machine

- spiral cutting machine

- spiral machine binding

- spiral machine for sale

- spiral machine price list

- spiral machine sheet metal

- spiral pipe making machine

- spiral tube making machine

- spiral pipe bending machine

- spiral tube forming machine

- spiral pipe machine for sale

- spiral rebar bending machine

- spiral symbol on washing machine

- automatic spiral punching machine

- double rotor spiral high speed slitting machine

- spiral duct machine price

- spiral binding machine price

- spiral binding machine australia

- spiral binding machine price list

- manual spiral binding machine price

- spiral binding machine lowest price

- spiral binding machine price sydney

- automatic spiral binding machine price