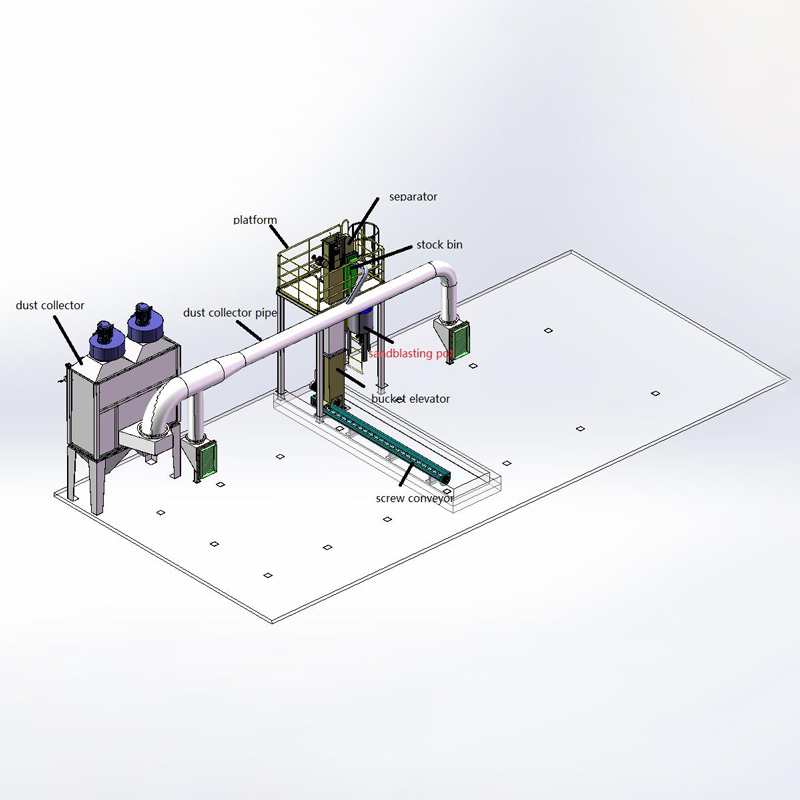

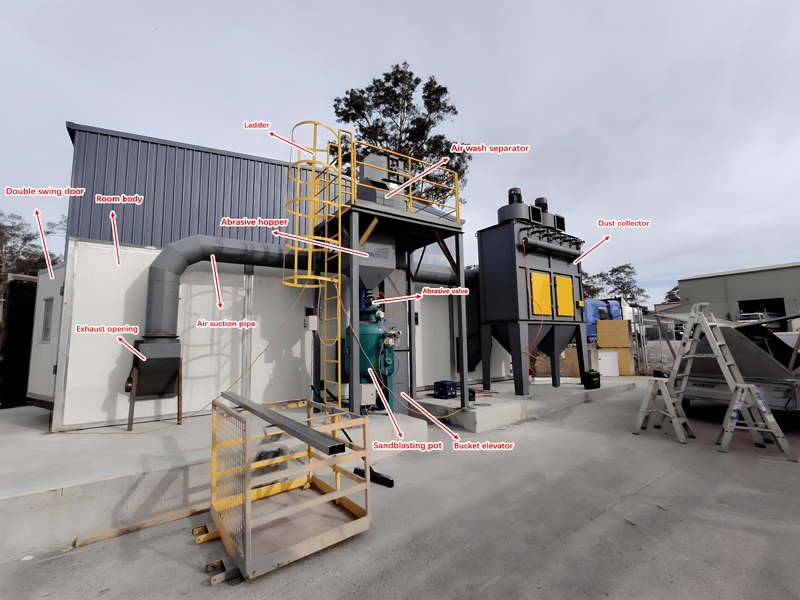

MultiBlast Recovery System & Dust Collector for Blasting Room (Single Screw Floor Recovery)

The MultiBlast Recovery System & Dust Collector, specifically designed for blasting rooms with a single screw floor recovery system. This comprehensive solution is engineered to optimise efficiency, safety, and environmental protection during abrasive blasting operations. Built by MultiBlast, a trusted name in industrial equipment, this system combines robust construction with innovative technology to ensure superior performance and longevity.

MultiBlast Recovery System & Dust Collector for Blasting Room (Single Screw Floor Recovery)

MultiBlast Recovery System & Dust Collector for Blasting Room (Single Screw Floor Recovery)

Description

Introducing the MultiBlast Recovery System & Dust Collector, specifically designed for blasting rooms with a single screw floor recovery system. This comprehensive solution is engineered to optimise efficiency, safety, and environmental protection during abrasive blasting operations. Built by MultiBlast, a trusted name in industrial equipment, this system combines robust construction with innovative technology to ensure superior performance and longevity.

Inclusion

- 1 Unit x Bucket elevator – Including housing, hood shield, middle shield , bottom shield, reduction box, elevator belt, buckets, etc

- 1 Unit x Separator – Including separation area, hopper, duct, fine abrasive storage hopper, abrasive dosing unit etc.

- 1 Unit x Floor recovery system – Single screw conveyor, reducer, etc

- 1 Unit x Cartridge filter dust collector – Including 11KW pressure centrifugal fan, 12 pcs cartridge filters, ducts, maintenance platform etc

- 1 Unit x Electric control system – Including power distribution cabinet, control cabinet, Schneider low voltage apparatus, etc.

Key Features and Inclusions:

-

Bucket Elevator: The bucket elevator is a critical component that ensures the efficient vertical transport of abrasive materials. It includes:

- Robust housing for durability

- Hood shield, middle shield, and bottom shield for enhanced protection

- High-quality reduction box and elevator belt

- A series of buckets designed to handle various abrasive materials efficiently

-

Separator: The separator unit plays a crucial role in maintaining the quality of the abrasive material. It features:

- A dedicated separation area for precise material sorting

- Hopper and duct system for smooth material flow

- Fine abrasive storage hopper to maintain material quality

- Abrasive dosing unit for controlled material feed

-

Floor Recovery System: Designed for seamless floor recovery, this system includes:

- Single screw conveyor for efficient material transport

- High-performance reducer to ensure consistent operation

-

Cartridge Filter Dust Collector: Ensuring a clean and safe working environment, the dust collector features:

- A powerful 11KW pressure centrifugal fan for effective dust extraction

- 12 pcs cartridge filters to capture fine particulates

- Comprehensive duct system for optimal airflow

- Maintenance platform for easy access and servicing

-

Electric Control System: The electric control system offers reliable and user-friendly operation, including:

- Power distribution cabinet for organised electrical management

- Control cabinet featuring Schneider low voltage apparatus for dependable performance

Advantages:

- Enhanced Efficiency: The integrated system components work together seamlessly to maximise operational efficiency.

- Safety and Environmental Protection: The advanced dust collector and separator systems minimise dust emissions, promoting a safer and cleaner workspace.

- Durability and Reliability: Constructed with high-quality materials and components, the MultiBlast system is built to withstand demanding industrial environments.

- Ease of Maintenance: Accessible design and maintenance platforms ensure routine servicing is straightforward, reducing downtime.

Applications: Ideal for a variety of abrasive blasting applications, this system is perfect for industries such as:

- Automotive

- Shipbuilding

- Metal fabrication

- Construction

Invest in the MultiBlast Recovery System & Dust Collector for your blasting room to experience superior performance, enhanced safety, and operational efficiency. Trust MultiBlast to deliver cutting-edge solutions tailored to meet your industrial needs.

MultiBlast Recovery System & Dust Collector for Blasting Room (Single Screw Floor Recovery) Diagrams

Additional information

Additional information

| Weight | 990 kg |

|---|

ABSS and MultiBlast are two leading brands in the field of industrial blasting equipment and surface preparation solutions. Whether you’re looking for an ABSS blast pot, ABSS sand blaster, or a MultiBlast blasting cabinet, both brands offer a wide array of options to suit industries like construction, manufacturing, and shipyards. ABSS is particularly well-known for its high-quality blasting products, including ABSS blasting equipment and ABSS soda blast cabinets, which excel in tasks like rust removal, weld cleaning, and paint stripping. Similarly, MultiBlast provides innovative alternatives like portable units and automation systems designed for high-volume manufacturing, making it a strong competitor in the market.

For businesses in cities like Sydney, Perth, Adelaide, or Keilor East, ABSS and MultiBlast offer tailored solutions for diverse applications. ABSS products are often praised for their cost-effectiveness in industrial settings and their focus on dust containment systems for indoor use, ensuring safety and environmental compliance. MultiBlast, on the other hand, stands out for its energy-efficient blasting machines and advanced automation technology, which are ideal for improving productivity in steel fabrication and construction site cleaning. Both brands provide excellent options for businesses seeking reliable and efficient blasting solutions.

When it comes to industrial cleaning applications, both ABSS and MultiBlast excel in providing advanced tools that are easy to use and maintain. ABSS offers comprehensive solutions, including training courses for construction teams, blast pressure settings for metal surfaces, and media selection guides for different industries. MultiBlast complements these features with innovations like water jetting alternatives and portable units for on-site construction, making it a versatile choice for various industrial needs. Whether you’re removing rust in shipyards or preparing concrete surfaces for new installations, these brands ensure high performance and quality control.

Choosing between ABSS and MultiBlast depends on your specific requirements, whether it’s for small manufacturers renting blasting machines or large-scale operations needing automation in high-volume manufacturing. Both brands prioritize safety, with detailed guidelines on blast safety protocols for construction workers and efficient dust containment systems. By offering such a wide range of options and features, ABSS and MultiBlast continue to be the go-to brands for businesses seeking reliable, eco-friendly, and high-performance blasting solutions.

- abss blast pot

- abss blast cabinet

- abss sandblaster

- abss blasting supply

- abss blasting equipment

- abss soda blast cabinet

- abss products blast cabinets

- abss sydney

- abss keilor east

- abss australia

- made in abss

- abss liluah

- abss jobs

- abss solutions

- abss prestons

- abss adelaide

- abss supplies

- abss perth

- abss sand blaster

- abss blast for industrial cleaning applications

- abss blast equipment for construction sites

- abss blast vs sandblasting in manufacturing

- abss blast surface preparation for steel fabrication

- abss blast cost-effectiveness in industrial settings

- abss blast for removing rust in shipyards

- abss blast safety protocols for construction workers

- abss blast machine rental for small manufacturers

- abss blast environmental impact in industrial use

- abss blast training courses for construction teams

- abss blast nozzle types for different materials

- abss blast pressure settings for metal surfaces

- abss blast maintenance tips for industrial equipment

- abss blast vs chemical cleaning in factories

- abss blast for concrete surface preparation

- abss blast dust containment systems for indoor use

- abss blast productivity rates in manufacturing

- abss blast for paint removal on industrial machinery

- abss blast portable units for on-site construction

- abss blast media selection guide for different industries

- abss blast automation in high-volume manufacturing

- abss blast for weld cleaning in metal fabrication

- abss blast energy efficiency in industrial applications

- abss blast quality control measures for construction

- abss blast vs water jetting for industrial cleaning