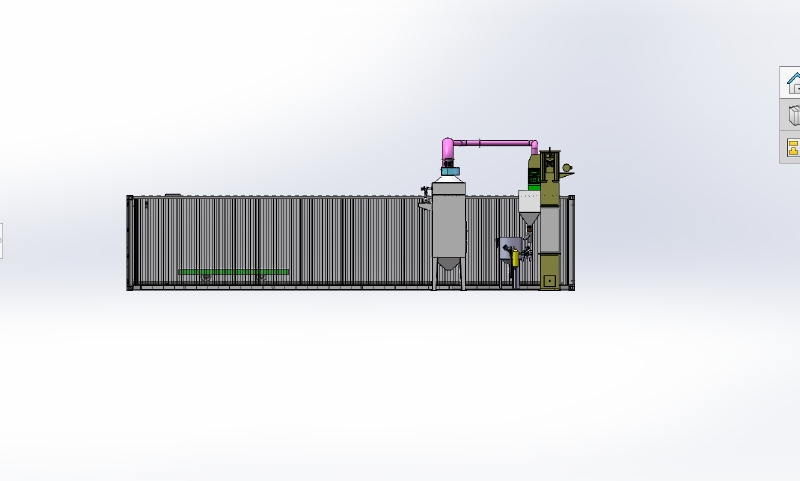

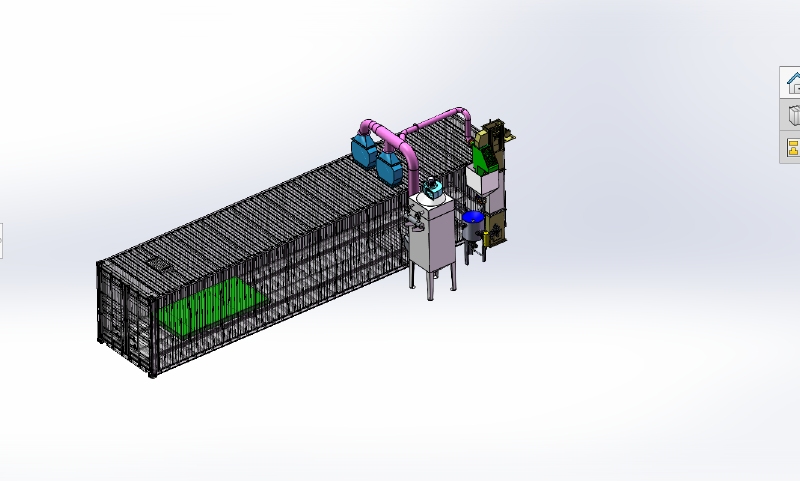

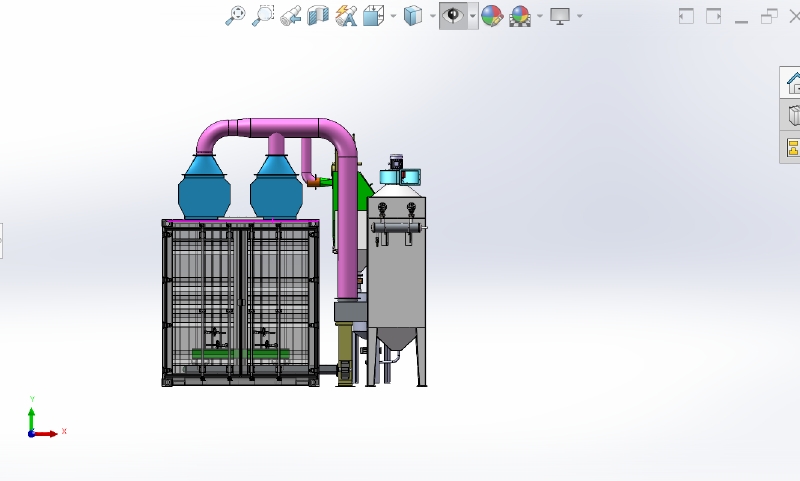

MultiBlast PROBRS6000 Blasting Room Container Blast System

The MultiBlast PROBRS6000 Blasting Room Container Blast System offer a wide range of Abrasive Blast Rooms in a variety of configurations for all types of cleaning, peening and finishing operations. MultiBlast PROBRS6000 also recognize the need for Blast Cleaning in remote locations and smaller Blast Operations and thus included into the range the Container Blast Room. A purpose built, easily relocatable system comprises all the features of the larger MultiBlast6000 Blast Rooms.

MultiBlast PROBRS6000 Blasting Room Container Blast System

MultiBlast PROBRS6000 Blasting Room Container Blast System

You may also like

-

$104,596.00 Excl. GST $115,055.60 Incl. GST Product ID: MULTIBLAST-PROBRS12000

MultiBlast PROBRS12000 Blasting Room Container Blast System

$104,596.00 Excl. GST $115,055.60 Incl. GST

Description

The MultiBlast PROBRS6000 Blasting Room Container Blast System offer a wide range of Abrasive Blast Rooms in a variety of configurations for all types of cleaning, peening and finishing operations. MultiBlast PROBRS6000 also recognize the need for Blast Cleaning in remote locations and smaller Blast Operations and thus included into the range the Container Blast Room. A purpose built, easily relocatable system comprises all the features of the larger MultiBlast6000 Blast Rooms.

Features:

- Recovery Floor Module located at one end.

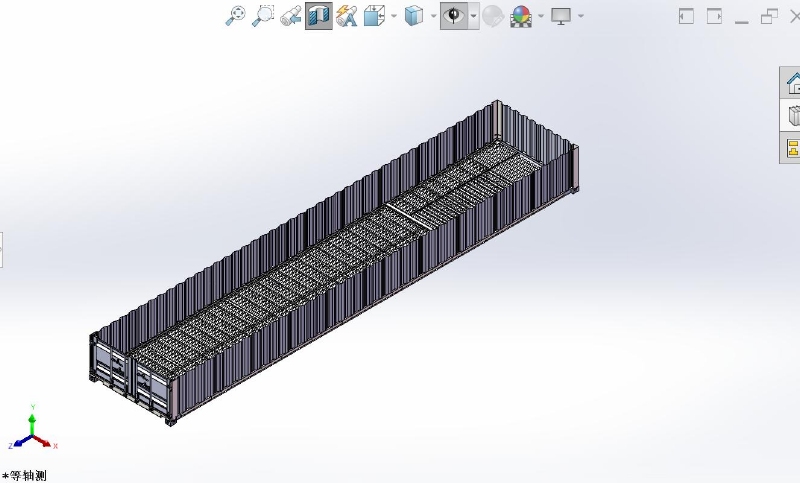

- 2400mm Wide x 2300mm High x 6000mm Deep NEW Hi-Cube Container.

- Pneumatic Deadman System integrated with Door Interlocks.

- Recovery 1.5 System includes Abrasive Air Wash Module.

- 4000CFM Reverse Pulse Dust Collector.

- Safety Door Interlocks on all doors.

- Six (6) – Standard length Energy saving LED Lights.

- Toughened Safety Glass Viewing Windows.

- MultiBlast Manufactured Recovery Components. (Australian Made)

- HD Blast Hose and Sized Blast Nozzle.

- Operator Safety Blast Helmet & Breathing Filters.

- Upgradable to High Cube Container design for increased internal space (Optional)

General Description

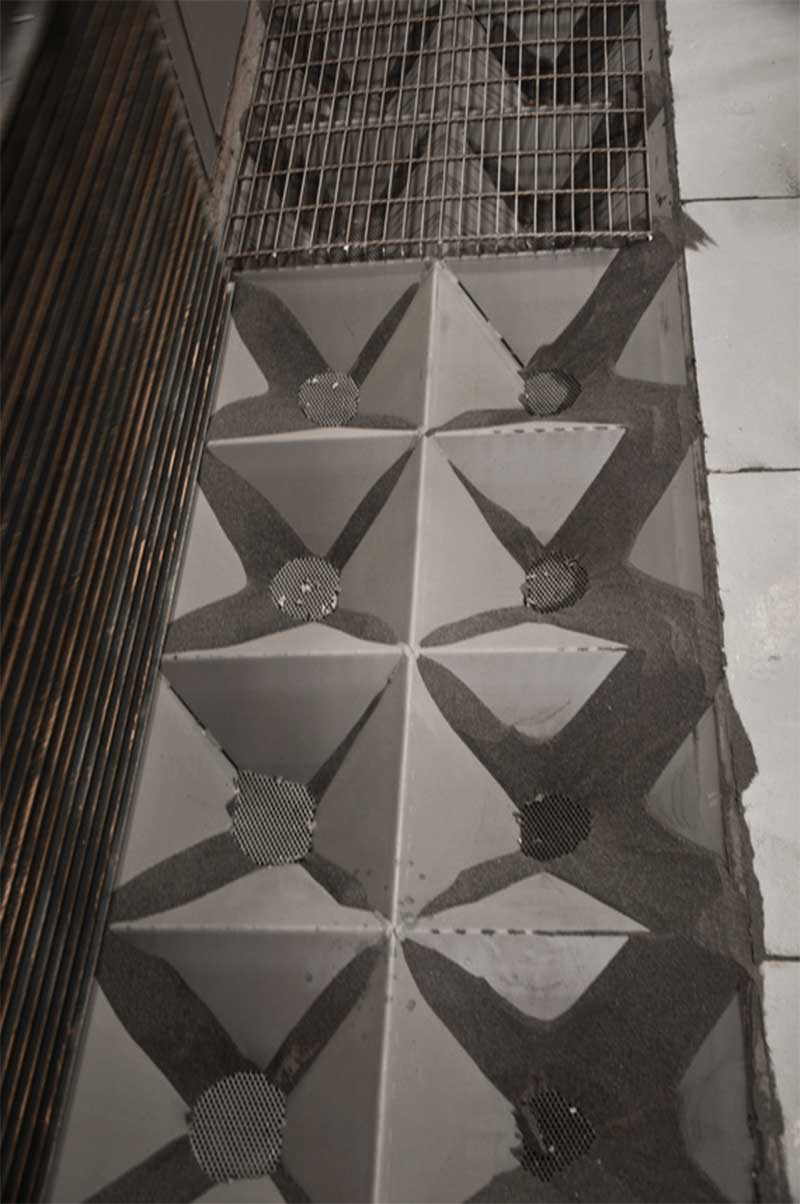

The Multiblast Blasting Room Container Blast System offers a unique means of Abrasive Recovery. In conjunction with the “W” Section Floor, a most efficient ventilation system is provided. This has some outstanding advantages when compared with other Blast Room designs. The economics of recycling durable Abrasive Media provides a very attractive payback on investment scenario. This system can conform to the requirements of AS1627-4 (Metal finishing – Preparation and pretreatment of surfaces – Abrasive Blast Cleaning of steel)

- A simplified design combining Down and End Draught Ventilation and pneumatic conveying in the same air movement

- Elimination of Mechanical Parts from the Abrasive Conveying system, reducing costly maintenance and breakdowns

- Clear Visibility for the Blast Operators comfort and effectiveness in sighting the blast target

- The Pneumatic Conveying system, in conjunction with the Abrasive Reclaimer, air washes the abrasive media before re-blasting, ensuring that dust and foreign matter are removed. This is particularly important where coatings such as Powder Coat, Paint, Metal Spray etc. are applied post Blast.

Wireframe Diagram

Option 1

- 1 Set x Blasting room body – 20FT container, wear resistant rubber guard plate, etc.

- 1 Set x Sand blasting machine – blasting pot, level gauge, 10m(1 pcs) blasting hose fast coupling connector, 1 sets of blasting gun with Φ10 Venturi nozzle

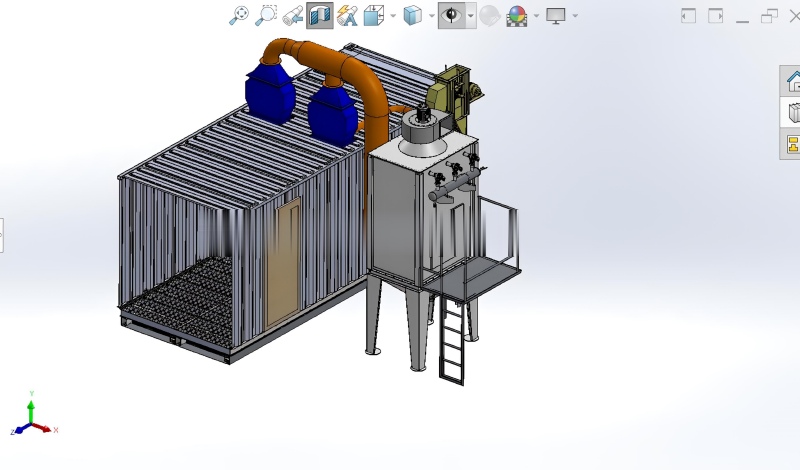

- 1 Set x Crosswise screw conveyor with shaft, Mn16 screw blades and housing

- 1 Set x Bucket elevator, including housing, hood shield, middle shield, bottom shield, reduction box, elevator belt, buckets, etc.

- 1 Set x abrasive separator, including separation area, hopper, duct, fine abrasive storage hopper etc.

- 4 Sets x Lighting fixtures, including LED lamp, Explosion-proof organic glass, etc.

- 1 Set x abrasive supply system – Including pneumatic gate valve, slide pipe, cylinder, etc.

- 1 Set x Dust collector, including pressure centrifugal fan, cartridge filters, ducts, maintenance platform etc.

- 1 Set x Electric control system, dust proof electric cabinet, failure warning, low voltage apparatus, etc.

Specification

| Production Name |

MultiBlast PROBRS6000

|

| Room Dimension |

6000 Length x 2400 Width x 2300 Height

|

| Total Power | 8.5 kw |

| Installation Requirements | |

| Supply Power | |

| Blasting Container | 20FT |

| Supply Voltage | 3 phase 415vac |

| Ampere | Approximately 17 Amps |

| Minimum Air Supply Requirement | |

| CFM | 230 CFM |

| LPM | 6500 LPM |

| Cleaning Effect | |

| Surface Preparation Level |

ISO 8501-1 – Sa 2.5

|

| Surface Preparation Level |

ISO8501-1:1988 40μm~80μm

|

| Abrasive Specification | |

| Initial Filling Capacity | 1 Tonne |

| Diameter | φ0.6~φ1.5 mm |

| Blasting Room |

1 x 20ft container

wear resistant rubber guard plate |

| 1 Set – Sandblasting Machine – Air Jet + Sand Blast | |

| Gun Quantity |

1 pcs (pneumatic remote control)

|

| Venturi Nozzle Diameter | Φ10 mm |

| Volume Of In-Tank | 0.3m3 |

| Emitted Dose | 1500-2500kg/h |

| Working Air Pressure | 5-8 bars |

| Floor Recovery System | |

| 1 Set – Crosswise Screw Conveyor Recovery System | |

| Delivery Capacity | 15t/h |

| Reduction Box Motor Power | Share with bucket elevator |

| 2 Set – Automatic Scraper Conveyor | |

| Pneumatic Cylinder Control |

Length: approx.: 12 meters

Delivery capacity: 15t/h |

| 1 Set – Bucket Elevator- | |

| Lifting Capacity | 15t/h |

| Power | 3kw |

| Speed | 1.6m/s |

| 1 Set – Abrasive Separator- | |

| Separation Capacity | 15t/h |

| Power |

Share the same with bucket elevator

|

| Multiple Level Air Wash Type – Storage Hopper And Abrasive Dosing Unit (Manual+Air Cylinder Control) | |

| Air Speed | 4-5m/s |

| Dust Collector Air Volume | 5000 m3/h |

| Ventilation Speed | 0.15m/s |

| Dust-Proof Led Lam | |

| Illumination | around 120 lx |

| Power | 4×50w |

| 1 Set – Fan Motor | |

| Centrifugal Fan Motor Power | 5.5kw |

| 1 Set – Dust Collector | |

| Cartridge Filters | HL-4 |

| Filter Brand | Donaldson |

| Effective Filtering Area | 60m2 |

| Dust Collecting Efficiency | ≥99.2% |

| Air Shock Valve For Filter With Timing Device | |

| 1Unit – Collection Silo | |

| Storage Capacity | 1 Tonne |

| Total Machine Noise | ≤60dB |

| 1 Unit – Electric Control System |

A mpere meter, Emergency stop,

Manual key switch, Contactor, Button, Indicator, Control element |

| Air Source |

Air compressor NOT Included

|

| Other requirements | |

| There are no other specific requirements other than access for the loading of products. | |

Additional information

Additional information

| Weight | 990 kg |

|---|---|

| Dimensions | 6000 × 2400 × 2300 cm |

- abrasive blast room

- abrasive blasting booth

- blast and paint room

- blast booth equipment

- blast booth for sale

- blast one melbourne

- blast room dust collector

- blast room engineering

- blast room recovery system

- blasting room mastering

- blasting room studios

- building a sandblasting room

- container sandblasting room

- containerized blast room

- how to build a sandblasting room

- industrial blast booth

- industrial blast rooms

- media blasting booth

- media blasting room

- modular blast room

- multiblast blast room equipment

- multiblast blast rooms

- portable blast booth

- portable sand blasting booth

- sand blast hire

- sand blast room dust collector

- sand blast room for sale

- sand blasting booth for sale

- sandblasting room design

- sandblasting room for sale

- sandblasting room price

- sandblasting room ventilation

- shipping container sandblast room

- walk in sandblast booth

- what is a blast room

ABSS and MultiBlast are two leading brands in the field of industrial blasting equipment and surface preparation solutions. Whether you’re looking for an ABSS blast pot, ABSS sand blaster, or a MultiBlast blasting cabinet, both brands offer a wide array of options to suit industries like construction, manufacturing, and shipyards. ABSS is particularly well-known for its high-quality blasting products, including ABSS blasting equipment and ABSS soda blast cabinets, which excel in tasks like rust removal, weld cleaning, and paint stripping. Similarly, MultiBlast provides innovative alternatives like portable units and automation systems designed for high-volume manufacturing, making it a strong competitor in the market.

For businesses in cities like Sydney, Perth, Adelaide, or Keilor East, ABSS and MultiBlast offer tailored solutions for diverse applications. ABSS products are often praised for their cost-effectiveness in industrial settings and their focus on dust containment systems for indoor use, ensuring safety and environmental compliance. MultiBlast, on the other hand, stands out for its energy-efficient blasting machines and advanced automation technology, which are ideal for improving productivity in steel fabrication and construction site cleaning. Both brands provide excellent options for businesses seeking reliable and efficient blasting solutions.

When it comes to industrial cleaning applications, both ABSS and MultiBlast excel in providing advanced tools that are easy to use and maintain. ABSS offers comprehensive solutions, including training courses for construction teams, blast pressure settings for metal surfaces, and media selection guides for different industries. MultiBlast complements these features with innovations like water jetting alternatives and portable units for on-site construction, making it a versatile choice for various industrial needs. Whether you’re removing rust in shipyards or preparing concrete surfaces for new installations, these brands ensure high performance and quality control.

Choosing between ABSS and MultiBlast depends on your specific requirements, whether it’s for small manufacturers renting blasting machines or large-scale operations needing automation in high-volume manufacturing. Both brands prioritize safety, with detailed guidelines on blast safety protocols for construction workers and efficient dust containment systems. By offering such a wide range of options and features, ABSS and MultiBlast continue to be the go-to brands for businesses seeking reliable, eco-friendly, and high-performance blasting solutions.

- abss blast pot

- abss blast cabinet

- abss sandblaster

- abss blasting supply

- abss blasting equipment

- abss soda blast cabinet

- abss products blast cabinets

- abss sydney

- abss keilor east

- abss australia

- made in abss

- abss liluah

- abss jobs

- abss solutions

- abss prestons

- abss adelaide

- abss supplies

- abss perth

- abss sand blaster

- abss blast for industrial cleaning applications

- abss blast equipment for construction sites

- abss blast vs sandblasting in manufacturing

- abss blast surface preparation for steel fabrication

- abss blast cost-effectiveness in industrial settings

- abss blast for removing rust in shipyards

- abss blast safety protocols for construction workers

- abss blast machine rental for small manufacturers

- abss blast environmental impact in industrial use

- abss blast training courses for construction teams

- abss blast nozzle types for different materials

- abss blast pressure settings for metal surfaces

- abss blast maintenance tips for industrial equipment

- abss blast vs chemical cleaning in factories

- abss blast for concrete surface preparation

- abss blast dust containment systems for indoor use

- abss blast productivity rates in manufacturing

- abss blast for paint removal on industrial machinery

- abss blast portable units for on-site construction

- abss blast media selection guide for different industries

- abss blast automation in high-volume manufacturing

- abss blast for weld cleaning in metal fabrication

- abss blast energy efficiency in industrial applications

- abss blast quality control measures for construction

- abss blast vs water jetting for industrial cleaning