MultiBlast PRO90S – 40 Litre – Multi Media Soda Blasting Pot System Package

If you are looking for a heavy-duty and compact blast pot ideal for industrial applications, the MultiBlast PRO90S – 40 Litre – Multi Media Soda Blasting System Package presents an ideal choice. This machine can be retrofitted to fit the Multi-Blast Sandblasting Cabinets, allowing the easy conversion from the suction blast to pressure blast. You can also install abrasive metering using the mini micro-abrasive valve feed.

MultiBlast PRO90S – 40 Litre – Multi Media Soda Blasting Pot System Package

MultiBlast PRO90S – 40 Litre – Multi Media Soda Blasting Pot System Package

You may also like

-

Product ID: MULTI-BLAST-SB80

-

Was $ 7,776 Excl. GST $ 8,554 Incl. GST Now Only$7,076.16 Excl. GST $7,783.78 Incl. GST Product ID: PRO180-80L-F

MultiBlast PRO180 – 80 Litre – Blast Pot Machine Full Package

Was $ 7,776 Excl. GST $ 8,554 Incl. GST Now Only$7,076.16 Excl. GST $7,783.78 Incl. GST -

MultiBlast PRO45 – 20 Litre – Sandblasting Pot Machine Full Package

Package Including Helmet & FilterWas $ 5,292 Excl. GST $ 5,821 Incl. GST Now Only$4,815.72 Excl. GST $5,297.29 Incl. GST Product ID: PRO45-20L-FMultiBlast PRO45 – 20 Litre – Sandblasting Pot Machine Full Package

Was $ 5,292 Excl. GST $ 5,821 Incl. GST Now Only$4,815.72 Excl. GST $5,297.29 Incl. GST -

Was $ 4,099 Excl. GST $ 4,508 Incl. GST Now Only$3,729.73 Excl. GST $4,102.70 Incl. GST Product ID: PRO45-20L-B

MultiBlast PRO45 – 20 Litre – Sandblasting Pot Machine Basic Package

Was $ 4,099 Excl. GST $ 4,508 Incl. GST Now Only$3,729.73 Excl. GST $4,102.70 Incl. GST -

Was $ 8,625 Excl. GST $ 9,488 Incl. GST Now Only$7,762.50 Excl. GST $8,538.75 Incl. GST Product ID: PRO420-185L-B

MultiBlast PRO420 – 185 Litre – Blasting Pot Machine Basic Package

Was $ 8,625 Excl. GST $ 9,488 Incl. GST Now Only$7,762.50 Excl. GST $8,538.75 Incl. GST -

MultiBlast PRO400 – 174 Litre – Blasting Pot Equipment Full Package

Package Including Helmet & FilterWas $ 9,396 Excl. GST $ 10,336 Incl. GST Now Only$8,550.36 Excl. GST $9,405.40 Incl. GST Product ID: PRO400-174L-FMultiBlast PRO400 – 174 Litre – Blasting Pot Equipment Full Package

Was $ 9,396 Excl. GST $ 10,336 Incl. GST Now Only$8,550.36 Excl. GST $9,405.40 Incl. GST -

Was $ 8,100 Excl. GST $ 8,910 Incl. GST Now Only$7,371.00 Excl. GST $8,108.10 Incl. GST Product ID: PRO320-140L-F

MultiBlast PRO320 – 140 Litre – Blasting Pot Machine Full Package

Was $ 8,100 Excl. GST $ 8,910 Incl. GST Now Only$7,371.00 Excl. GST $8,108.10 Incl. GST

Frequently Asked Questions

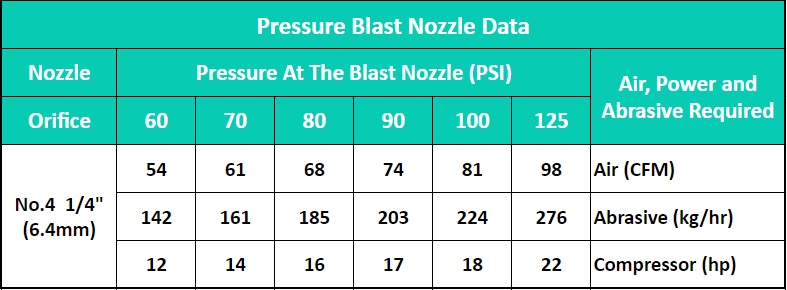

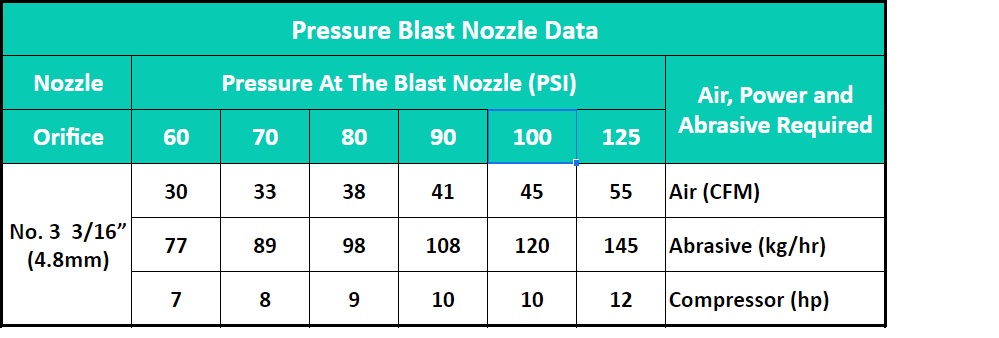

What size compressor do I require?

Different nozzles maybe fitted to reduce the air supply demand. However, there are some restrictions on certain models.

Please refer to Nozzle selection chart.

What assembly is required?

What size grit is recommended to use?

What maintenance is required?

Do I require an air dryer or aftercooler for my compressor ?

Description

MultiBlast Blast Pots have been designed to cater to a diverse range of blasting requirements. Ideal for professional contractors, these commercial robust blast pots deliver consistent efficient blasting capabilities and are suitable for all types of blasting applications. The multimedia blast valve delivers the flexibility to blast with Garnet, Walnut Shell, Glass, Soda, Plastic beads and many other types of blast media.

- Australian designed and manufactured with full backup and support

- Pneumatic remote control (Dead man trigger)

- Adjustable multi-media blast valve

- Long lasting carbide tipped blast nozzle

- Built to Australian Standards AS1210

- Efficient reliable operation

- 2 Year Warranty

Package Comes with:

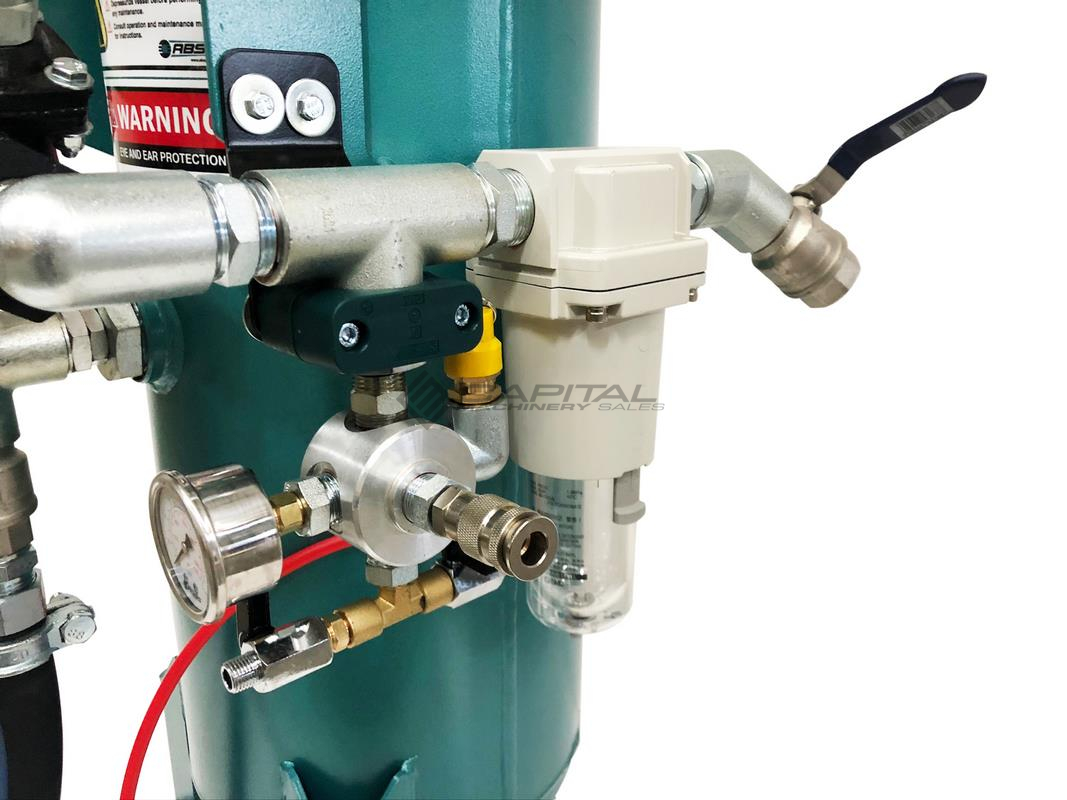

- 1-1/4″ (32NB) Micro Abrasive Feed Valve

- 1/2″ (12mm) Filter Regulator

- Lid & Screen

- Pneumatic Deadman Controls, Hose & Handle

- 10m – 19mm x 34mm DuraBlast Hose

- ATW4 1/4″ (6.4mm) Venturi Blast Nozzle

- Blast Helmet

- Breathing Filter Kit

- 12m Fitted Breathing Hose

- Pneumatic Vibrator Assembly for Sandblasting

Technical Information:

The ideal blasting pressure for these blasting packages is 100 PSI. When considering the compressor capacity required, allow an additional 15CFM for the blasting filter and helmet. It is best practice to allow another 20% on top of the total CFM calculated so the compressor is not operating above its recommended duty cycle. This package fitted with a No. 4 Blast nozzle, the required minimum air supply demand is 115 CFM.

Optional No:3 Blast Nozzle for reduced air supply requirements

The ideal blasting pressure for these blasting packages is 100 PSI. When considering the compressor capacity required, allow an additional 15CFM for the blasting filter and helmet. It is best practice to allow another 20% on top of the total CFM calculated so the compressor is not operating above its recommended duty cycle. This package fitted with a No. 3 Blast nozzle, the required minimum air supply demand is 72 CFM.

See MultiBlast Sand Blasting Pots And Blasting Equipment For Sale In Australian Demo

MultiBlast PRO90 Blast Demostration

- sand blaster

- sand blasting near me

- blast one

- sandblasting sydney

- sandblasters melbourne

- sandblasting kit

- abrasive blaster

- advanced sandblasting

- small sandblaster

- sand blaster for sale

- industrial sandblasting

- dustless blaster for sale

- sand blasting equipment

- sandblasting dandenong

- sandblasting media bunnings

- sandblasting equipment for sale

- sandblasting services

- portable sand blaster

- sandblasting sand

- sandblasting glass

- blasting supplies

- sandblasting sand bunnings

- sandblaster booth

- sandblasting garnet

- pot sale

- sandblasting brisbane southside

- mobile sandblasting sydney

- sandblasting mackay

- blasting soda for sale

- sand blasting machine for sale

- sandblasting unit

- sandblasting business for sale

- sandblasting cairns

- on site sandblasting

- sandblasting rust

- sandblasting supplies brisbane

- sandblasting prices australia

- sandblasting prices

- sandblasting compressor

- sandblasting cost

- sandblasting launceston

- how much does sandblasting cost

- sandblasting townsville

- sandblasting darwin

- sandblasting hoppers crossing

- sandblasting media for sale

- sandblasting melbourne northern suburbs

- sandblasting melbourne western suburbs

- sandblasting nsw

ABSS and MultiBlast are two leading brands in the field of industrial blasting equipment and surface preparation solutions. Whether you’re looking for an ABSS blast pot, ABSS sand blaster, or a MultiBlast blasting cabinet, both brands offer a wide array of options to suit industries like construction, manufacturing, and shipyards. ABSS is particularly well-known for its high-quality blasting products, including ABSS blasting equipment and ABSS soda blast cabinets, which excel in tasks like rust removal, weld cleaning, and paint stripping. Similarly, MultiBlast provides innovative alternatives like portable units and automation systems designed for high-volume manufacturing, making it a strong competitor in the market.

For businesses in cities like Sydney, Perth, Adelaide, or Keilor East, ABSS and MultiBlast offer tailored solutions for diverse applications. ABSS products are often praised for their cost-effectiveness in industrial settings and their focus on dust containment systems for indoor use, ensuring safety and environmental compliance. MultiBlast, on the other hand, stands out for its energy-efficient blasting machines and advanced automation technology, which are ideal for improving productivity in steel fabrication and construction site cleaning. Both brands provide excellent options for businesses seeking reliable and efficient blasting solutions.

When it comes to industrial cleaning applications, both ABSS and MultiBlast excel in providing advanced tools that are easy to use and maintain. ABSS offers comprehensive solutions, including training courses for construction teams, blast pressure settings for metal surfaces, and media selection guides for different industries. MultiBlast complements these features with innovations like water jetting alternatives and portable units for on-site construction, making it a versatile choice for various industrial needs. Whether you’re removing rust in shipyards or preparing concrete surfaces for new installations, these brands ensure high performance and quality control.

Choosing between ABSS and MultiBlast depends on your specific requirements, whether it’s for small manufacturers renting blasting machines or large-scale operations needing automation in high-volume manufacturing. Both brands prioritize safety, with detailed guidelines on blast safety protocols for construction workers and efficient dust containment systems. By offering such a wide range of options and features, ABSS and MultiBlast continue to be the go-to brands for businesses seeking reliable, eco-friendly, and high-performance blasting solutions.

- abss blast pot

- abss blast cabinet

- abss sandblaster

- abss blasting supply

- abss blasting equipment

- abss soda blast cabinet

- abss products blast cabinets

- abss sydney

- abss keilor east

- abss australia

- made in abss

- abss liluah

- abss jobs

- abss solutions

- abss prestons

- abss adelaide

- abss supplies

- abss perth

- abss sand blaster

- abss blast for industrial cleaning applications

- abss blast equipment for construction sites

- abss blast vs sandblasting in manufacturing

- abss blast surface preparation for steel fabrication

- abss blast cost-effectiveness in industrial settings

- abss blast for removing rust in shipyards

- abss blast safety protocols for construction workers

- abss blast machine rental for small manufacturers

- abss blast environmental impact in industrial use

- abss blast training courses for construction teams

- abss blast nozzle types for different materials

- abss blast pressure settings for metal surfaces

- abss blast maintenance tips for industrial equipment

- abss blast vs chemical cleaning in factories

- abss blast for concrete surface preparation

- abss blast dust containment systems for indoor use

- abss blast productivity rates in manufacturing

- abss blast for paint removal on industrial machinery

- abss blast portable units for on-site construction

- abss blast media selection guide for different industries

- abss blast automation in high-volume manufacturing

- abss blast for weld cleaning in metal fabrication

- abss blast energy efficiency in industrial applications

- abss blast quality control measures for construction

- abss blast vs water jetting for industrial cleaning