MultiBlast-HyperAir PRO390W-560S All-in-One Wet Blasting and Vari-Speed Screw Compressor Package System

The MultiBlast-HyperAir PRO390W-560S All-in-One Wet Blasting and Vari-Speed Screw Compressor Package System, offers an innovative solution to surface preparation by blending wet blasting power with advanced compressed air technology reliability.

MultiBlast-HyperAir PRO390W-560S All-in-One Wet Blasting and Vari-Speed Screw Compressor Package System

MultiBlast-HyperAir PRO390W-560S All-in-One Wet Blasting and Vari-Speed Screw Compressor Package System

Frequently Asked Questions

What is the difference between a Wet Blasting Cabinet and a Dry Blasting Cabinet?

Wet Blasting cabinets are designed to clean and polish components. The process is dust free and does not require a dust

filtration system. (Ideal for Automotive applications)

Dry Blasting cabinets are designed to strip coating like paint, remove rush and profile materials in preparation to coating.

(Suitable for manufacturing or equipment restoration)

What is the difference between dry blasting vs wet blasting

Wet Blasting cabinets are designed to clean and polish components. The process is dust free and does not require a dust filtration system. (Ideal for Automotive applications) while the Dry Blasting cabinets are designed to strip coating like paint, remove rush and profile materials in preparation to coating. (Suitable for manufacturing or equipment restoration).

What material is used to manufacture the blasting cabinets ?

(Some low end US manufacturers use - Fibre glass, plastic or thin galvanised sheet greatly reducing durability)

Are closed loop, water recirculating systems available?

Typically, we do not recommend closed-loop systems as they require a significant amount of space and are usually unnecessary for most applications.

Description

The MultiBlast-HyperAir PRO390W-560S All-in-One Wet Blasting and Vari-Speed Screw Compressor Package System, offers an innovative solution to surface preparation by blending wet blasting power with advanced compressed air technology reliability.

Utilizing advanced wet abrasive blasting combines abrasive media, compressed air, and water for superior cleaning and polishing. This method eliminates airborne dust and delivers a finer surface finish compared to dry blasting. Whether you are cleaning, polishing, or refining materials, this dynamic duo guarantees professional results with ease. Enhance your workflow with precision, efficiency, and reliability.

Features of MultiBlast PRO390W

- Durable Grade 304 stainless steel cabinet, designed to resist corrosion and wear for long-lasting durability.

- Safeguard your blast area with the resilience of white rubber lining, designed to withstand heavy use.

- Hands-free operation with convenient foot pedal controls, allowing you to focus on precision.

- Heavy duty latex rubber work gloves for maximum hand protection and dexterity for handling intricate tasks.

- Adjustable air pressure regulator to meet the specific needs of your project, ensuring optimal performance.

- Maintain clear visibility of your work area with an automated window wiper for uninterrupted workflow.

- Easily rinse your projects with a powerful wash down gun.

- Keep the air inside the cabinet clean and clear with an efficient exhaust system.

| Model | MultiBlast PRO390W |

| Installed Dimensions |

680mm Wide x 680mm Deep x 1670mm High

|

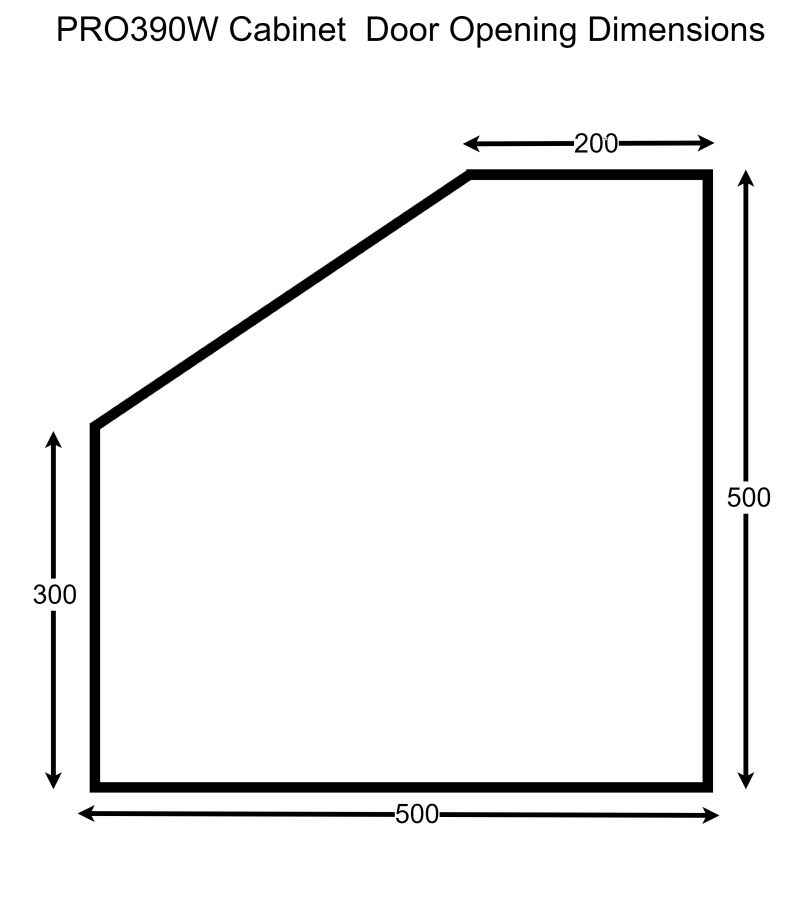

| Door Dimensions | 520mm wide x 480mm high |

| Power Requirement |

Standard: 415vac Three Phase 10 Amp

Optional: 240vac Single Phase 10 Amp |

| CFM Required |

565L/min @ 6.89 Bar (20cfm @ 100 psi)

|

| Air Connection Size | 13mm (1/2″) |

| Water Connection Size | 13mm (1/2″) |

| Blast Gun Size |

3mm (1/8″) Air Tip x 8mm (5/16″) Blast Nozzle

|

| Cabinet Light | 13W |

MultiBlast PRO390W Wet Blasting Cabinet

Pairing the MultiBlast PRO390W with the HyperAir VARI-ECO 560S Screw Compressor brings a new level of efficiency and versatility to your workshop. This compressor operates on single-phase 220V power, making it suitable for a wide range of scenarios from residential to commercial settings. With frequency conversion technology, you can expect small starting currents and energy consumption costs that are about half of industrial electricity expenses.

Features of HyperAir VARI-ECO 560S

- Energy efficiency: 220V frequency conversion motors are 50% more energy-efficient than ordinary motors, saving you money and reducing your carbon footprint.

- Advanced separation technology, ensures the oil content at the export is controlled to 2ppm, maintaining a clean and efficient system.

- The compressor features six heavy-duty bearings and a Morse taper connection, controlling vibration frequency within 1mm/s for smooth operation.

- Efficiency up to 95%, “IE4” high energy efficiency motor

- Constant and silent airflow, perfect for maintaining a peaceful workspace.

- Designed with a large size air end and low speed, this compressor provides sufficient air volume for all your needs.

- Simple installation and maintenance ensure minimal downtime and maximum productivity.

| Model |

HyperAir ECO 560S

|

| Air Flow |

0.57m3/min (20cfm)

|

| Discharge Pressure |

0.8MPa (116PSI)

|

| Motor | 4.5KW |

| Horsepower | 6HP |

| Electricity |

240V/50HZ/1Phase

|

| Max. Rated Current (Special Outlet Required) |

16.7amp |

| Air Tank | 100L |

| Air End |

Customized IP23 Zoncn Inverter

|

| Dimension |

1020 x 540 x 1035 mm

|

| Weight | 120kg |

See MultiBlast Wet Blasting Cabinet (Video Demo)

See MultiBlast Wet Blasting Cabinet (Setup)

MultiBlast Wet Blasting / Vapour Blasting Cabinet – Blasting Samples

Additional information

Additional information

| Weight | 370 kg |

|---|

ABSS and MultiBlast are two leading brands in the field of industrial blasting equipment and surface preparation solutions. Whether you’re looking for an ABSS blast pot, ABSS sand blaster, or a MultiBlast blasting cabinet, both brands offer a wide array of options to suit industries like construction, manufacturing, and shipyards. ABSS is particularly well-known for its high-quality blasting products, including ABSS blasting equipment and ABSS soda blast cabinets, which excel in tasks like rust removal, weld cleaning, and paint stripping. Similarly, MultiBlast provides innovative alternatives like portable units and automation systems designed for high-volume manufacturing, making it a strong competitor in the market.

For businesses in cities like Sydney, Perth, Adelaide, or Keilor East, ABSS and MultiBlast offer tailored solutions for diverse applications. ABSS products are often praised for their cost-effectiveness in industrial settings and their focus on dust containment systems for indoor use, ensuring safety and environmental compliance. MultiBlast, on the other hand, stands out for its energy-efficient blasting machines and advanced automation technology, which are ideal for improving productivity in steel fabrication and construction site cleaning. Both brands provide excellent options for businesses seeking reliable and efficient blasting solutions.

When it comes to industrial cleaning applications, both ABSS and MultiBlast excel in providing advanced tools that are easy to use and maintain. ABSS offers comprehensive solutions, including training courses for construction teams, blast pressure settings for metal surfaces, and media selection guides for different industries. MultiBlast complements these features with innovations like water jetting alternatives and portable units for on-site construction, making it a versatile choice for various industrial needs. Whether you’re removing rust in shipyards or preparing concrete surfaces for new installations, these brands ensure high performance and quality control.

Choosing between ABSS and MultiBlast depends on your specific requirements, whether it’s for small manufacturers renting blasting machines or large-scale operations needing automation in high-volume manufacturing. Both brands prioritize safety, with detailed guidelines on blast safety protocols for construction workers and efficient dust containment systems. By offering such a wide range of options and features, ABSS and MultiBlast continue to be the go-to brands for businesses seeking reliable, eco-friendly, and high-performance blasting solutions.

- abss blast pot

- abss blast cabinet

- abss sandblaster

- abss blasting supply

- abss blasting equipment

- abss soda blast cabinet

- abss products blast cabinets

- abss sydney

- abss keilor east

- abss australia

- made in abss

- abss liluah

- abss jobs

- abss solutions

- abss prestons

- abss adelaide

- abss supplies

- abss perth

- abss sand blaster

- abss blast for industrial cleaning applications

- abss blast equipment for construction sites

- abss blast vs sandblasting in manufacturing

- abss blast surface preparation for steel fabrication

- abss blast cost-effectiveness in industrial settings

- abss blast for removing rust in shipyards

- abss blast safety protocols for construction workers

- abss blast machine rental for small manufacturers

- abss blast environmental impact in industrial use

- abss blast training courses for construction teams

- abss blast nozzle types for different materials

- abss blast pressure settings for metal surfaces

- abss blast maintenance tips for industrial equipment

- abss blast vs chemical cleaning in factories

- abss blast for concrete surface preparation

- abss blast dust containment systems for indoor use

- abss blast productivity rates in manufacturing

- abss blast for paint removal on industrial machinery

- abss blast portable units for on-site construction

- abss blast media selection guide for different industries

- abss blast automation in high-volume manufacturing

- abss blast for weld cleaning in metal fabrication

- abss blast energy efficiency in industrial applications

- abss blast quality control measures for construction

- abss blast vs water jetting for industrial cleaning