Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

- Brand: Matrix

1000 in stock

Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

You may also like

-

$37,840.00 Excl. GST $41,624.00 Incl. GST Product ID: MATRIX1530125HT

-

Product ID: LMN3015H3-3

Description

Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

Product Information

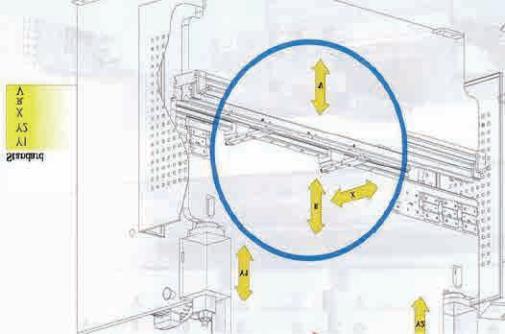

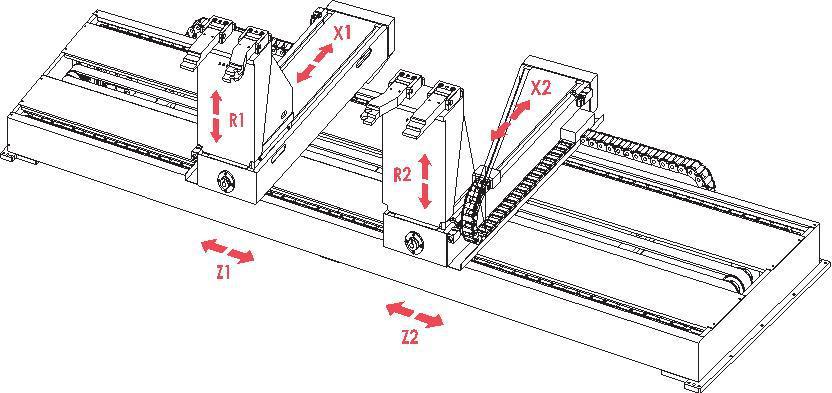

The entire EU streamlined design and heat-treated frame provide high rigidity. The WC67K series press brake comes with a standard single-axis backgauge system (X-axis) and a single-axis bending angle system (Y-axis). Optional features include the R-axis and V-axis compensation function, allowing for easy bending of workpieces with complex shapes. Hydraulic synchronization control and the TP10S CNC programmable logic controller ensure precise repeatability and user-friendly operation. The integrated hydraulic system from Bosch Rexroth, Germany, enables quick and automatic switching to a slow bend. The TP10S system programs the X-axis, Y-axis, and R-axis for accurate positioning.

Advanced variable frequency hydraulic control technology ensures stable and reliable operation. Optimal parameter ratio and core configuration guarantee stable performance and convenient operation.

Controller

- TP10S is a powerful and efficient press brake CNC system for CO-TRUST. Its control system and 7-inch Touch Screen interface enhance usability and user-friendliness.

- The X and Y positioning axes can be manually adjusted, eliminating the need for a device positioning manipulator. The system features integrated dwell time and function settings for time download, simplifying operations without requiring a time relay and reducing costs. The backup and restore function allows for easy restoration of settings as needed, minimizing maintenance costs. Additionally, it supports programming in multiple steps, enabling the execution of complex processes and enhancing production efficiency and precision machining.

- All key panels undergo rigorous testing, including exposure to high temperatures, vibrations, and other conditions, ensuring product stability and long-lasting service. Microswitching by CEM guarantees reliable performance.

- CE certified to meet the needs of foreign market

TP10S CNC System Features :

- Menu programming interface

- Equipped with servo motor

- The CAN open bus control mode eliminates interference and positioning error completely.

- The system supports angle programming and automatically calculates the bending depth of plates. It also allows for slider position control and rear stop position control.

- The pressure maintenance time is set to 20 procedures, with 20 work steps for each procedure. The soft limit function ensures power-off memory.

- Power protection function

TECHNICAL SPECIFICATIONS

| Item | Unit |

| Bending Force | 1350mm |

| Bending Length | 3200mm |

| Columns Distance | 2600mm |

| Throat Depth | 380mm |

| Cylinder Stroke (Y1, Y2) | 200mm |

| Max Open Height | 400mm |

| Y-axis down speed | 150 mm/sce |

| Y-axis return speed | 150 mm/sce |

| Y-axis working speed | 150 mm/sce |

| Y-axis accuracy | 0.05mm |

| Work-piece linearity | 0.3mm |

| Max. back gauge distance | 500mm |

| X-axis and R-axis speed | 170 mm/sce |

| X-axis and R-axis accuracy | 0.05mm |

| Front sliding arms | 2pcs |

| Hydraulic Oil | #46 |

| Back gauge finger stopper | 3pcs |

| Main motor | 11kw |

| Length | 3750mm |

| Width | 1800mm |

| Height | 2500mm |

| Weight | 7500 kg |

STANDARD COMPONENTS

| Controller | TP10S |

| Backgauge Axis | Y axis + Y axis |

| Hydraulic Valve | Rexroth from Germany |

| Hydraulic Gear Pump | Sunny from USA |

| Foot Switch | Korea |

| Main Motor | Siemens from Germany |

Matrix QPB 135T/3200mm CNC Press Brake Machine with TP10S System

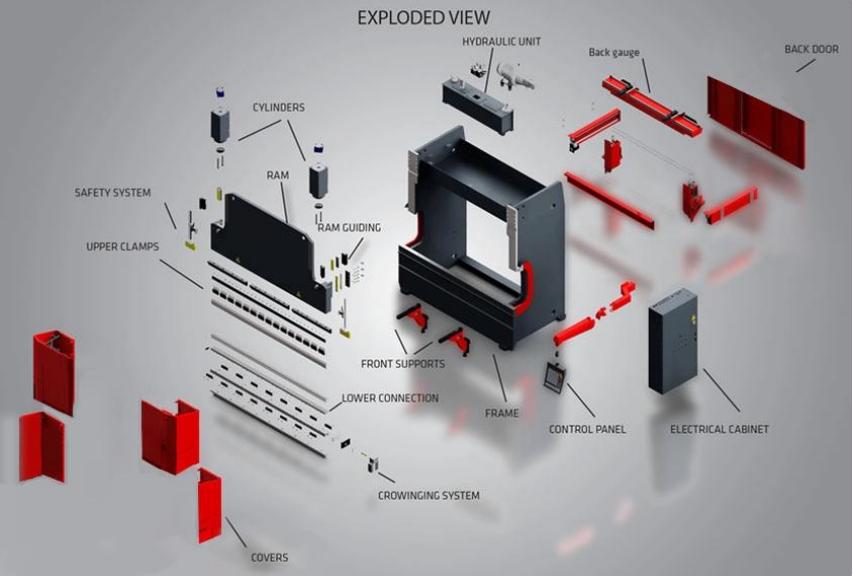

Configuration

- RIGID FRAME CONSTRUCTION – Every press brake is built on a sturdy, single-piece frame made of high-yield steel that is mill certified. This ensures accurate and reliable performance. Our confidence in our frames is reflected in our 10-year warranty for our standard machines. Dual hydraulic cylinders on both sides of the ram ensure quicker speed. The cylinders are synchronized, resulting in smooth motion and precise ram positions with accuracies of up to .0004″.

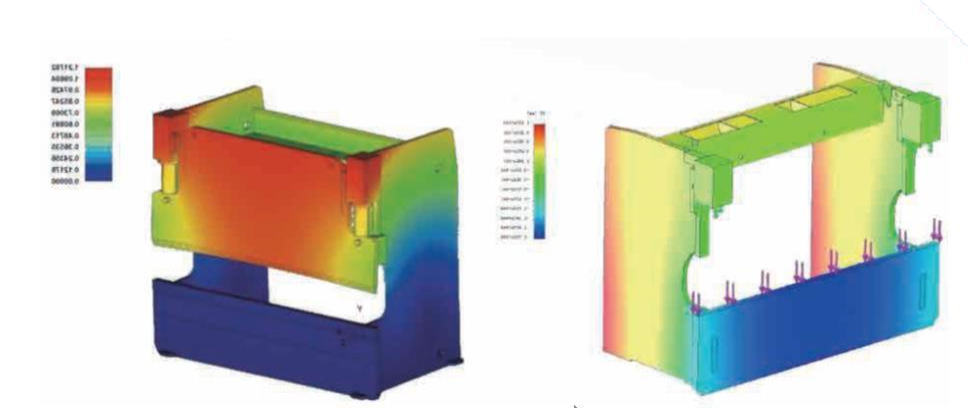

The CAE software SOLIDWORKS is utilized to analyze the linear static construction, stress, and deformation of press brake and laser cutting machine frames.

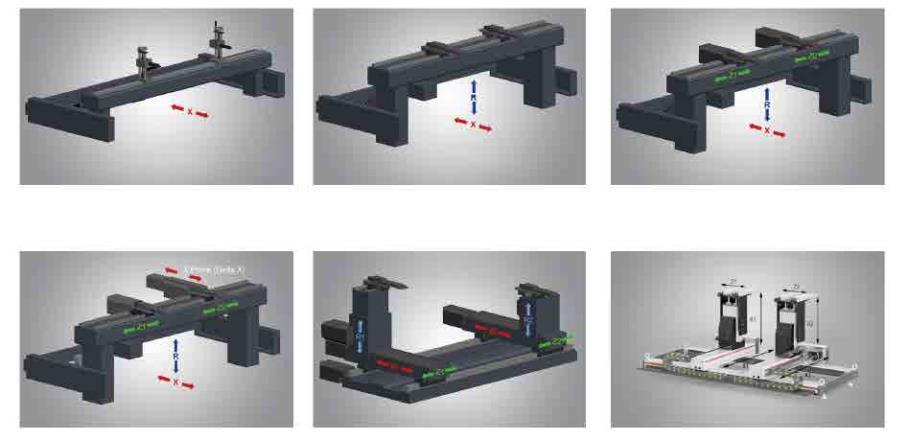

- CNC Back Gauge – For workpieces requiring precise bending in multiple steps, X is moved using a ball screw, guided by a linear guide, and driven by a digital AC servo-motor. The back gauge offers sufficient mechanical strength and rigidity with its tank-type gauge structure. The two fingers move independently, guided by a swallow guide, making operation easy and precise. The back gauge also features a finger-stop design that expands its range.

There are various options for back gauges, offering higher configuration, more powerful functions, and easier operation.

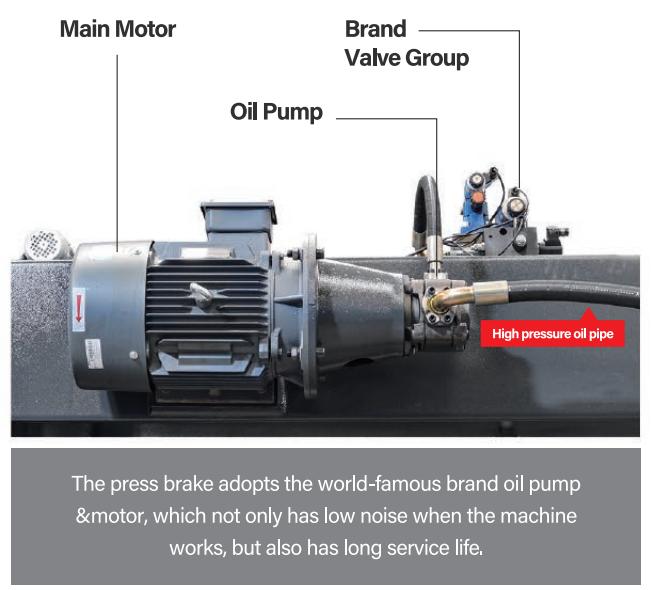

- Siemens Motor Germany – The press brake uses a renowned brand oil pump and motor, ensuring quiet operation and extended service life

- High Precision And Fast Clamping – Quickly clamping the upper die is convenient, reducing labor intensity and boosting production efficiency. This utility model offers high precision, easy clamping, and prevents loosening and tool dropping.

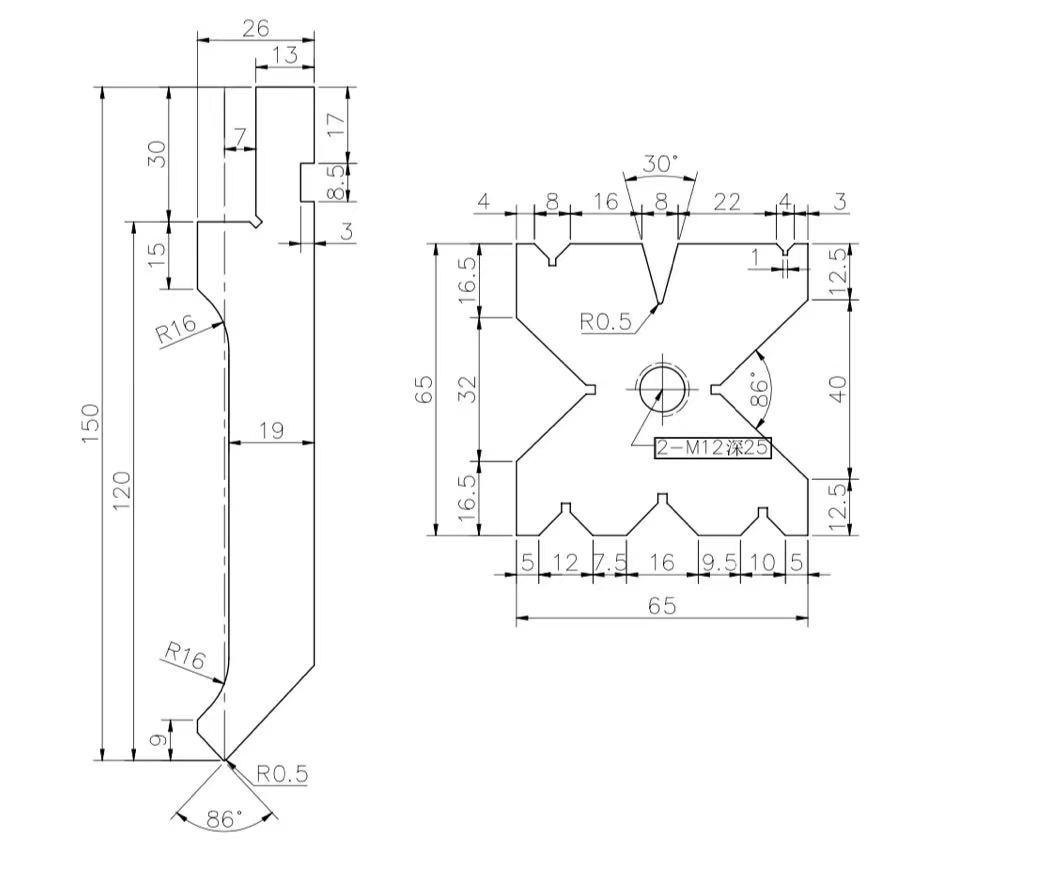

- Punch & Die – The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected baked on your needs.

- High Precision Backgauge – The backgauge utilizes a ball screw lever and high-end servo motor for fast, stable, and durable operation.

- Backgauge Fingers – It can be adjusted to meet bending requirements and enhance bending accuracy.

- Sunny Oil Pump – Features low noise levels and made of durable cast iron. It has a unique design for reducing internal noise and low sensitivity to oil pollution, ensuring a long service life.

- Hydraulic System – Utilizes the BOSCH-REXROTH integrated hydraulic control system, which reduces pipe connections for improved reliability and easier maintenance.

- Torsion-sync Bar – Torsion-sync principle controls the up and down movement of the ram.

- Moveable Front Support System – The front support is movable and can be parked at any position along the linear guide rail. It also has rotation and height adjustment functions to assist with bending.

- Schneider Electrical Parts – Utilizes Schneider electrical components. These high-quality electric parts ensure optimal machine performance.

- Moveable Pedal Switch

Options:

- Laser Safety Protection – The DSP laser protection device, imported from Italy, ensures comprehensive and effective safety protection for the bending machine, safeguarding the operator’s personal well-being.

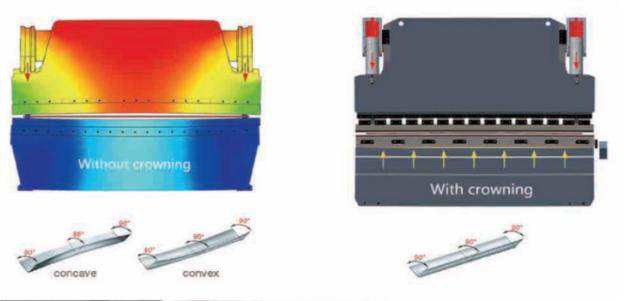

Manual Worktable Compensation

Standard Punch and Die Drawing

- Standard tooling: Use a double-V bottom die with high-quality steel material (42Crmo or C45). The material undergoes hot treatment to achieve an HRC of 47±2°

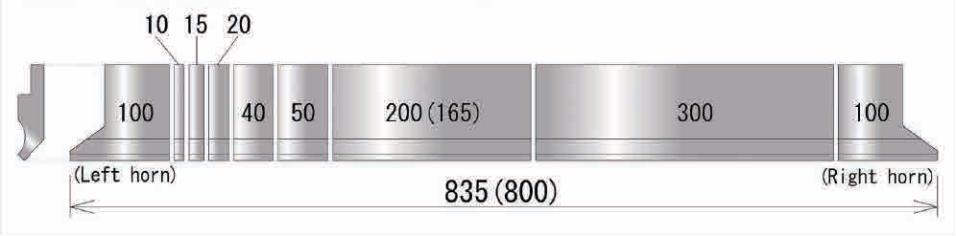

Standard section:

Additional information

Additional information

| Weight | 990 kg |

|---|---|

| Dimensions | 375 × 165 × 250 cm |

Reviews

- press brake

- brake press

- sheet metal brake plans free download

- pressbrake

- brake machine

- sheet metal press

- press break

- press brake tooling

- brake machining

- break press

- press brake operator

- press breaker

- solidworks spring

- brake press tooling

- press brake machine

- cnc press brake

- hydraulic press brake

- press brake dies

- amada press brake

- used press brake

- used sheet metal equipment

- bending break

- cnc brake press

- brake press machine

- hydraulic brake press

- brake presses

- bending press

- press bending

- hydraulic brake animation

- brake form

- press brake tool

- cnc sheet bending machine

- cnc press brake jobs

- hydraulic press break

- hydraulic press brakes

- press brake tools

- table top hydraulic press

- brake press dies

- sheet metal brake press

- hydraulic metal brake

- used brake press

- hydraulic bending machine

- hydraulic die press

- cnc press

- brake dies

- used press brake dies

- hydraulic metal press

- mechanical press brake

- hydraulic press brake manufacturers

- used hydraulic press brake

- pneumatic bending machine