Matrix GS6X3200 Guillotine Shear

- Brand: Matrix

In stock

Transform your metalworking with the Matrix GS6X3200 Guillotine Shear, a powerful combination of precision engineering and robust design that brings efficiency and accuracy to your workshop floor. Every element of the Matrix GS6X3200 Guillotine Shear comes together to deliver precise cuts with minimal fuss. From light scribing to effortless manual cuts, this shear is a testament to what modern engineering can bring to metal fabrication.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Matrix GS6X3200 Guillotine Shear

Matrix GS6X3200 Guillotine Shear

Description

Transform your metalworking with the Matrix GS6X3200 Guillotine Shear, a powerful combination of precision engineering and robust design that brings efficiency and accuracy to your workshop floor. Every element of the Matrix GS6X3200 Guillotine Shear comes together to deliver precise cuts with minimal fuss. From light scribing to effortless manual cuts, this shear is a testament to what modern engineering can bring to metal fabrication.

Features

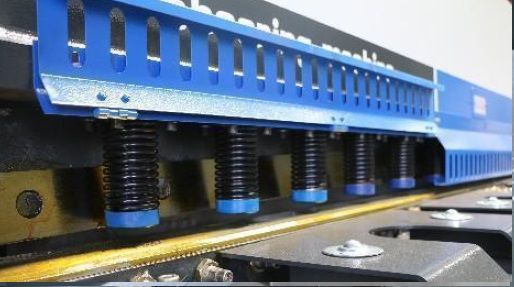

- Inspired by the best in EU design, this machine boasts a superior rack, cutter holder, oil cylinder, and hydraulic controller, all crafted for peak performance.

- Ensuring lasting durability, critical components have been meticulously analyzed and treated to eliminate stress, achieving unparalleled structural strength.

- Friction is no match for the rolling guide rail that guarantees a smooth operation of the cutter holder.

- Enhance your productivity with easy-to-use adjustment features that streamline the cutting process.

- A simple yet sophisticated CNC adjustment mechanism accurately sets the blade clearance, optimizing the quality of each cut.

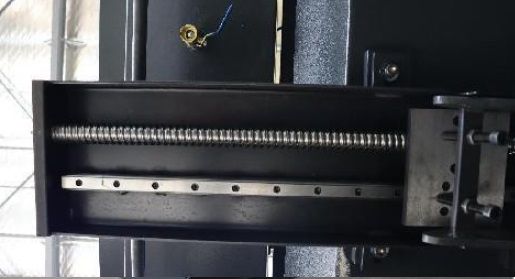

- The back gauge operates with a fine ball screw and bar structure, ensuring precise positioning with every cut.

- A hydraulic system that minimizes leak-related issues, coupled with a stable and reliable hydraulic transmission for consistent performance.

- The high-quality alloy tool steel blades stand up against high wear and impact, maintaining sharpness cut after cut.

- Operation is a breeze thanks to the user-friendly interface, with a rolling ball worktable to minimize friction and scratch-free operation.

- A safety guard device keeps operators secure, meeting stringent safety standards without compromising on accessibility or ease of use

Standard Equipment

- E21S CNC Control System

- Hydraulic Valve

- SIEMENS Main Motor

- Oil Pump

- Front Working Table

- Hydraulic press cylinder

- Backgauge

- Ball Screw and Linear Guide

- Adjusting Device for blade gap

- Step Motor for Backguage

- Main Electrical Components

- Knife Gap Adjustment

Inclusion

| Item | Unit | Quantity(In total) |

| Bottom screw | pieces | 4 |

| Rims | pieces | 4 |

| Oil gun | piece | 1 |

| Seals | set | 1 |

| Front support arms | set | 1 |

| Feet switch | piece | 1 |

Technical Specifications

| Model | Matrix GS6X3200 |

| Cutting Capacity <450N/mm2 | 6 mm |

| Cutting Capacity <700N/mm2 | 3 mm |

| Cutting Length | 3200 mm |

| Throat Depth | 150 mm |

| Cutting Angle | 0.5-1.5 degree |

| Back Gauge Distance | 500 mm |

| Back Gauge Speed | 100 mm / sec |

| Sliding Front Arms Quantity | 4 pcs. |

| Sliding Front Arms Length | 800 mm |

| Main Motor Power | 7.5 kw |

| Size | 4100×1700×2000 mm |

| Weight | 6500 kg |

Specification

Additional information

| Weight | 990 kg |

|---|---|

| Dimensions | 410 × 170 × 200 cm |

| Shipping Weight | 6500 kg |

Reviews

- press brake

- brake press

- sheet metal brake plans free download

- pressbrake

- brake machine

- sheet metal press

- press break

- press brake tooling

- brake machining

- break press

- press brake operator

- press breaker

- solidworks spring

- brake press tooling

- press brake machine

- cnc press brake

- hydraulic press brake

- press brake dies

- amada press brake

- used press brake

- used sheet metal equipment

- bending break

- cnc brake press

- brake press machine

- hydraulic brake press

- brake presses

- bending press

- press bending

- hydraulic brake animation

- brake form

- press brake tool

- cnc sheet bending machine

- cnc press brake jobs

- hydraulic press break

- hydraulic press brakes

- press brake tools

- table top hydraulic press

- brake press dies

- sheet metal brake press

- hydraulic metal brake

- used brake press

- hydraulic bending machine

- hydraulic die press

- cnc press

- brake dies

- used press brake dies

- hydraulic metal press

- mechanical press brake

- hydraulic press brake manufacturers

- used hydraulic press brake

- pneumatic bending machine