Edge Extender Bandsaw Water Soluble Cooling Oil 20L

Edge Extender Anti-Wear is a high quality, special purpose lubricant ideal for a broad range of Machinery Application. The high oil content provides excellent physical lubricity for the cutting operation as well as protection for the machine tool. This product can be used on ferrous and nonferrous metals.

Edge Extender Bandsaw Water Soluble Cooling Oil 20L

Edge Extender Bandsaw Water Soluble Cooling Oil 20L

Description

Edge Extender Bandsaw Water Soluble Cooling Oil

Edge Extender Anti-Wear is a high quality, special purpose lubricant ideal for a broad range of Machinery Application including:

-Bandsaws

– cold saws

– Drilling

– Grinding

– Milling & Turning

Suitable for all types of Steel & Aluminum.

Edge Extender Anti-Wear Formula has been engineered to both cool and lubricate cutting edges eliminating premature wear prolonging service life while completely protecting the equipment for rust, oxidation and corrosion.This product can be used on ferrous and nonferrous metals.

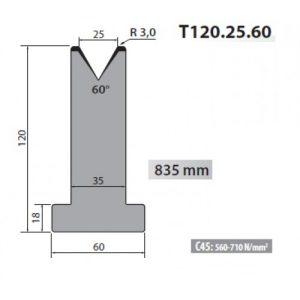

Specification

Additional information

| Weight | 22 kg |

|---|

When it comes to precision machining, using the right cutting fluid or coolant can make all the difference. Whether you’re working with aluminum, stainless steel, or cast iron, high-quality cutting fluids like water-soluble coolants, mineral cutting oils, or semi-synthetic fluids ensure smoother operations, reduced heat, and longer tool life. At Capital Machinery Sales Australia, we feature a wide range of cutting fluids, including options for CNC machining, heavy-duty metal cutting, and eco-friendly alternatives, tailored to meet the needs of any industrial or workshop application.

For industries that demand exceptional performance, our collection includes water-soluble oils, synthetic cutting fluids, and semi-synthetic coolants designed for precision machining and high-speed metal cutting. These cutting fluids not only improve machining efficiency but also maintain superior surface finish quality. Capital Machinery Sales Australia offers cutting oils perfect for applications like aluminum machining, soft metals like copper, and even cast iron, ensuring your tools perform at their best while minimizing wear and tear.

Capital Machinery Sales Australia also caters to workshops seeking cost-effective and reliable solutions. From affordable semi-synthetic cutting oils for small businesses to high-performance machining coolants for industrial processes, we have the perfect match for your needs. Our products, such as Castrol soluble cutting oils and water-soluble coolants, are ideal for heavy machining, lathe machines, and automotive metal forming applications. Additionally, we provide guidance on selecting the best cutting fluid for improving machining efficiency and reducing tool wear.

For environmentally conscious businesses, we offer eco-friendly cutting fluids and water-miscible coolants that align with sustainable machining practices. Our range includes cutting fluid replacements designed for durability and reduced environmental impact. With Capital Machinery Sales Australia, you’ll find the best machining fluids, from synthetic coolants for high-temperature processes to water-based fluids for cast iron and CNC operations. Explore our solutions today and experience the difference in quality and performance that our cutting fluids bring to your operations.

- metal cutting coolant

- metal cutting fluid

- metal cutting oil

- aluminium cutting fluid

- water soluble oil

- soluble oil coolant

- best cutting fluid

- best cutting oil

- best machining coolant

- cutting fluid oil

- cutting fluid price

- cutting fluids properties

- cutting oil application

- cutting oil price

- cutting oil properties

- cutting oil replacement

- cutting tool coolant

- cutting tool oil

- excision cutting fluid

- industrial cutting oil

- mineral cutting oil

- semi synthetic coolant

- synthetic cutting fluid

- water based coolant

- water miscible coolant

- water soluble coolant

- cutting oil for aluminium

- cutting fluid water soluble

- water soluble cutting coolant

- water soluble cutting fluid

- water soluble cutting oil

- castrol soluble cutting oil

- cool tool cutting fluid

- coolant oil for machining

- cutting fluid for copper

- mineral oil cutting fluid

- oil based cutting fluids

- semi synthetic cutting fluid

- semi synthetic metalworking fluid

- water soluble machine coolant

- water soluble mineral oil

- water soluble oil coolant

- cutting fluid for cast iron

- cutting fluids used in machining

- cutting oil shop near me

- water soluble cutting oil price

- difference between cutting fluid and coolant

- application of cutting fluids in machining processes

- best water soluble cutting fluid for aluminum

- affordable cutting oil for machining

- cutting fluid for high precision machining

- water soluble cutting oil for lathe machines

- industrial cutting oil suppliers near me

- metalworking fluid for CNC machining

- eco-friendly cutting fluids for metalworking

- benefits of synthetic cutting fluids in machining

- cutting oil for stainless steel applications

- high-performance machining coolant for aluminum

- semi-synthetic cutting oil for complex machining

- how to choose the best cutting oil for machining

- water-based cutting fluid for cast iron

- cost-effective soluble cutting oil for workshops

- synthetic vs. semi-synthetic cutting fluids

- cutting fluids for heavy-duty metal cutting

- best machining fluids for industrial processes

- properties of water soluble cutting fluids

- maintenance of cutting oil in machining processes

- difference between synthetic and water soluble coolants

- metalworking fluids for precision machining tools

- machine coolant for high-speed metal cutting

- how to apply cutting fluid in CNC machining

- long-lasting cutting fluids for industrial use

- water soluble coolant for bandsaw applications

- advantages of using semi-synthetic metalworking fluids

- cutting fluid for soft metals like copper and aluminum

- water soluble cutting oil for small workshops

- cutting fluid for improving machining efficiency

- synthetic coolant for high-temperature machining processes

- choosing the right cutting oil for tool longevity

- metal forming fluids for automotive applications

- cutting oil replacement for environmentally friendly options

- machining fluids for reducing tool wear

- water miscible coolant for heavy machining

- castrol soluble cutting oil for professional use

- best cutting fluid for cast iron machining

- oil-based coolant for industrial metalworking processes

- cutting fluids for maintaining surface finish quality

- advantages of using mineral oil cutting fluids

- affordable semi-synthetic cutting oils for small businesses

- water soluble machine coolant for improved lubrication

- cutting fluid suppliers for industrial-scale operations

- machining coolants for extended tool life

- water-based cutting fluids for sustainable machining practices

- high-quality cutting oils for CNC machine operations

- industrial solutions for cutting fluid disposal

- best coolant for minimizing heat during machining.

- coolant oil for lathe machine

- synthetic coolant oil

- coolant oil used in cnc machine

- coolant oil for machining

- engine coolant oil

- industrial coolant oil

- soluble oil coolant

- oil based coolant

- cnc machine coolant oil

- oil in coolant

- coolant oil price

- coolant oil for cnc machines

- coolant oil cost

- coolant oil types

- coolant oil safety

- coolant oil storage

- coolant oil testing

- coolant oil disposal

- coolant oil handling

- coolant oil ph level

- coolant oil supplier

- coolant oil additives

- coolant oil recycling

- coolant oil standards

- coolant oil viscosity

- coolant oil compliance

- coolant oil efficiency

- coolant oil filtration

- coolant oil monitoring

- coolant oil pour point

- coolant oil properties

- industrial coolant oil

- coolant oil composition

- coolant oil flash point

- coolant oil for cutting

- coolant oil for milling

- coolant oil for turning

- coolant oil maintenance

- coolant oil performance

- coolant oil regulations

- coolant oil applications

- coolant oil for drilling

- coolant oil for grinding

- coolant oil manufacturer

- coolant oil productivity

- coolant oil concentration

- coolant oil for machining

- coolant oil health hazards

- coolant oil for lubrication

- coolant oil quality control

- coolant oil waste reduction

- coolant oil cooling capacity

- coolant oil for cnc machines

- coolant oil for metalworking

- coolant oil emulsion stability

- coolant oil foaming resistance

- coolant oil corrosion resistance

- coolant oil environmental impact

- coolant oil for heat dissipation

- coolant oil antioxidant properties

- coolant oil for industrial equipment