Drillmaster 1200/500 Multi CNC Beam Drilling Line

- Brand: Capital Machinery Sales

In stock

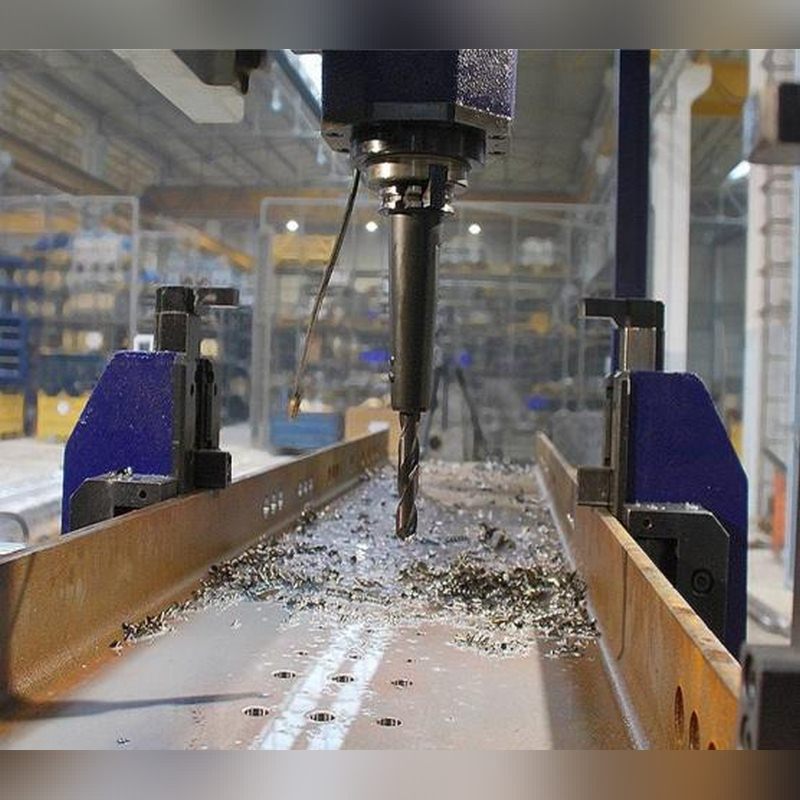

The DRILLMASTER is a fully integrated multi spindle CNC controlled drilling line, designed for beam processing. This allows the 3 drilling spindles to position individually or simultaneously for drilling, tapping, scribing, and milling along a working length of 500mm without repositioning of the material. This feature offers greatly enhanced, productivity, efficiency, and reduced processing time in just one operation.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Drillmaster 1200/500 Multi CNC Beam Drilling Line

Drillmaster 1200/500 Multi CNC Beam Drilling Line

Description

The DRILLMASTER is a fully integrated multi spindle CNC controlled drilling line, designed for beam processing.

This allows the 3 drilling spindles to position individually or simultaneously for drilling, tapping, scribing, and milling along a working length of 500mm without repositioning of the material. This feature offers greatly enhanced, productivity, efficiency, and reduced processing time in just one operation.

They are used in major sectors such as:

- General Steel Structures

- Offshore manufacturers

- Bridge manufacturers

- Tower manufacturers

- General Steel Suppliers

- Electrical Power Plant Builders

- Truck and crane manufacturers

The standard configurations consist of:

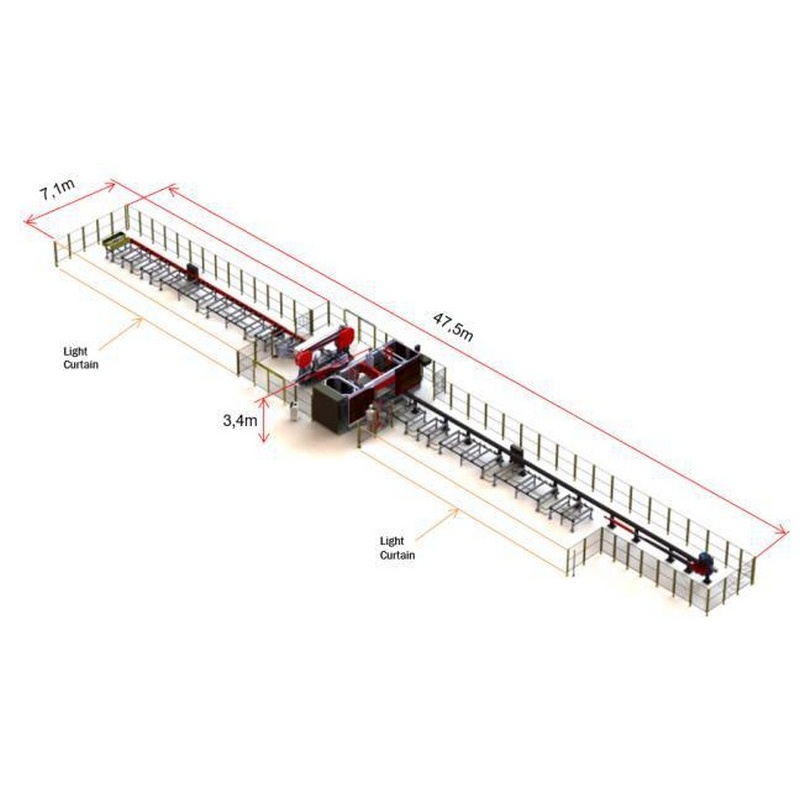

- Input Conveyor

- Beam Drilling Centre

- Output Conveyor.

Some optional stations are:

- Extension for in-feed and out-feed

- Transfer tables on in-feed and out-feed.

- Marking Station

- Bandsaw station

- Chip conveyor

Working principle with standard configuration:

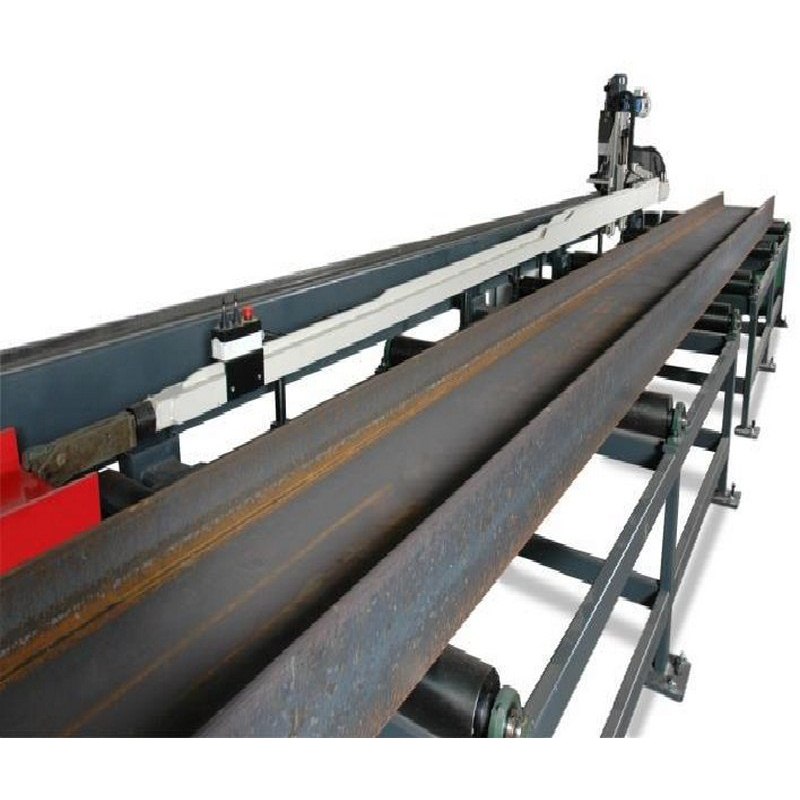

- The DRILLMASTER DM1200 Multi CNC beam drilling line holds the beam with a heavy-duty CNC controlled gripper. It feeds and positions the beams into the drill station.

- Once positioned inside the drilling station, the beam is held in position by horizontal hydraulic driven clamps on the side and a hydraulic vertical driven clamp from the top of the machine.

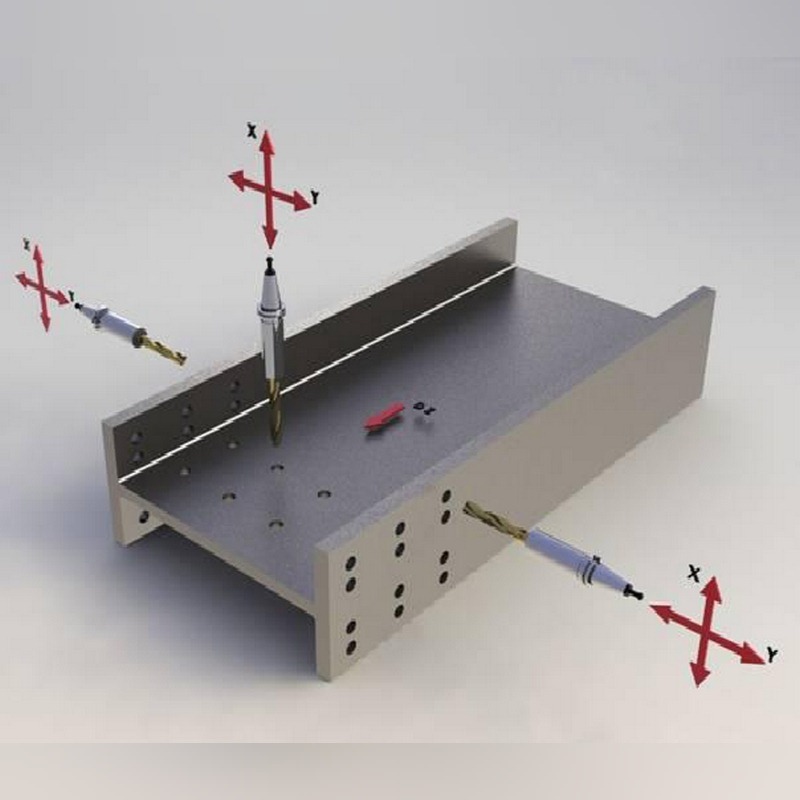

- The drilling process is performed by the 3 independent Drilling units on 3 individual axes. Each drill unit is controlled on it’s own independent ball screw axis and linear guide bearings, driven and positioned by a servo motor. The Drill heads have an independent X-axis travel distance of 500mm, without repositioning the beam.

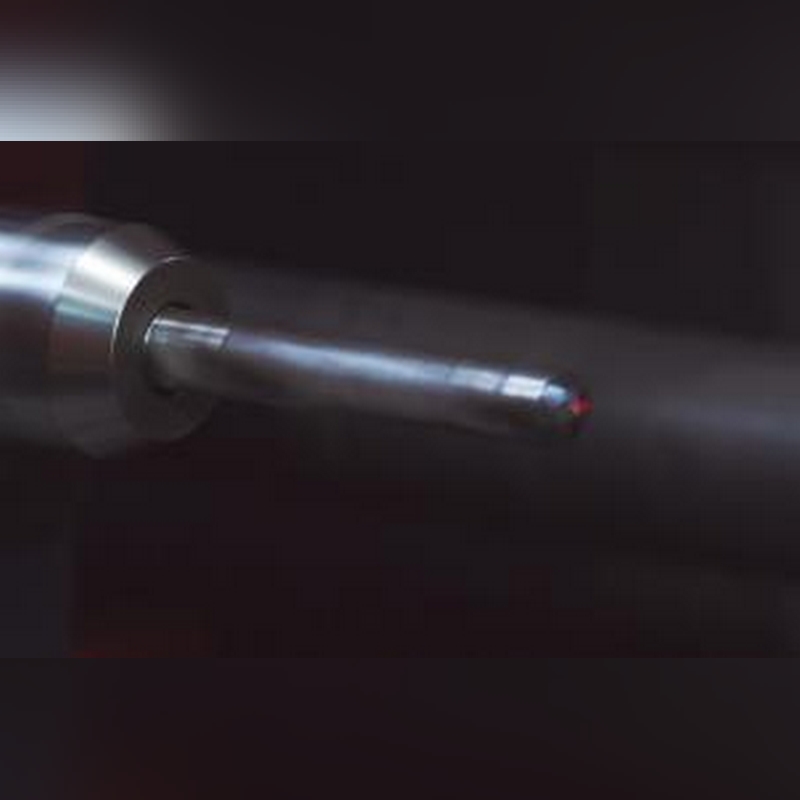

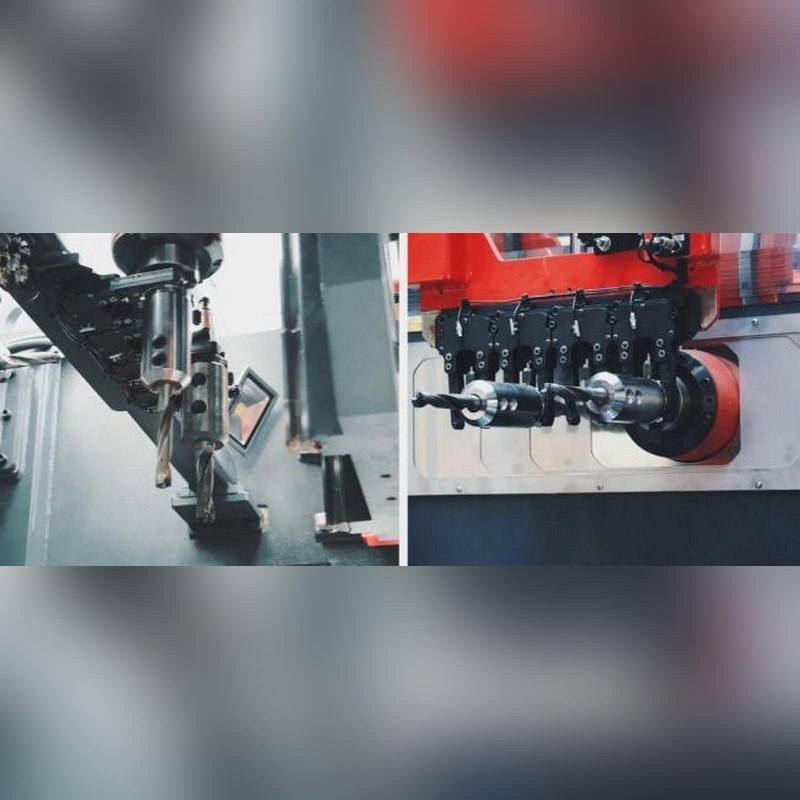

- The drilling units are using an internal cooling system with U-Drill (carbide drills). The cooling system includes air and pulverized cooling liquid. Each spindle has an Automatic Tool Changer with 4 tools capacity.

- The optional marking process is done by a dedicated marking unit. This process can be completed as an integrated step at any time.

- The end cutting process is performed by an optional band saw machine. The feeding of the beam is done by the input conveyor system. During cutting, a hydraulic clamp holds the beam in position.

- The processed beams will be carried to the output conveyor.

BEAM CAPACITY AS PER CUSTOMERS REQUIREMENTS:

Beam length: 12000mm Beam with: 1200mm Beam height: 500mm Maximum thickness: 32mmIN-FEED CONVEYOR

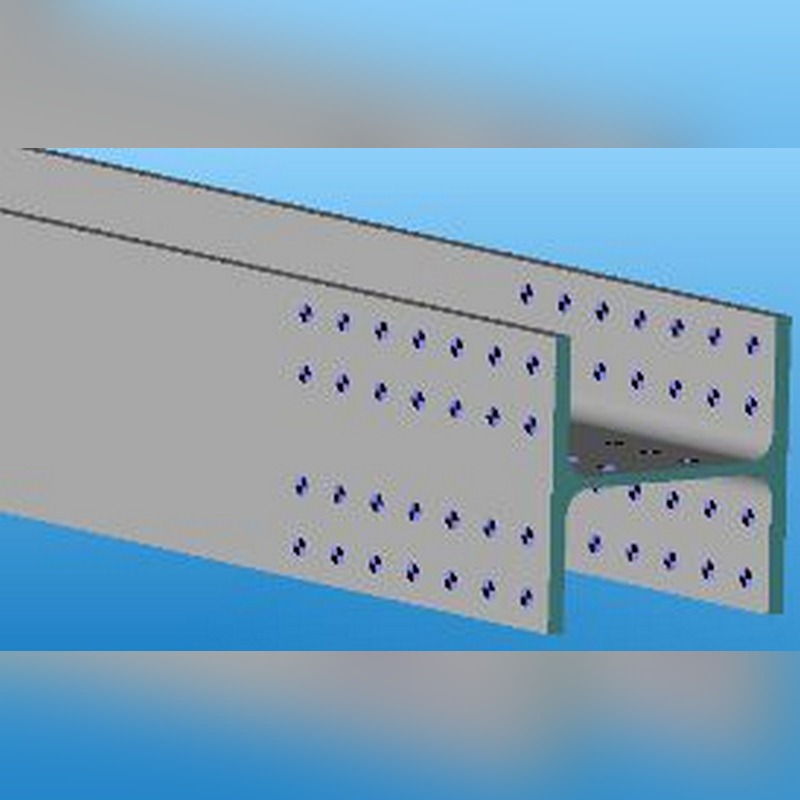

Powered in-feed for beams up to 12000mm long. Rolls are suitably spaced to allow the possible insertion of cross loading tables. The feeding arm moves forward and backwards, up and down and can push the beam thru the drilling station. Rolls centerline distance: 900mm Width of the rolls: 1500 mm AC drive motor: Servo controlledHORIZONTAL AND VERTICAL DRILLING UNITS

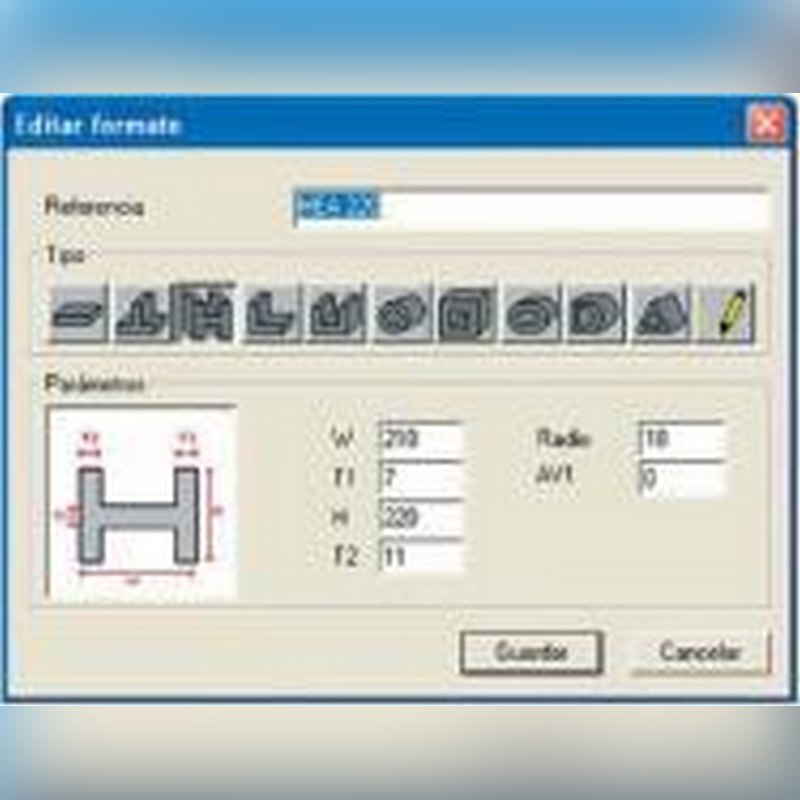

The drilling process is performed by the 3 independent drilling units. Two Drilling heads are placed in horizontal position, and one drilling head is placed vertically. Each drill unit is controlled on its' own independent ball screw axis and linear guide bearings, driven, and positioned by a servo motor. Each drill head can independently or simultaneously drilling, tapping, scribing, and milling along 500mm length of the beam without repositioning the material. This feature offers greatly enhanced, productivity, efficiency and reduced processing time by just one operator.All 3 drilling heads have the following specifications:

- 2 Horizontal mono drill heads are positioned on each side of the flanges.

- Maximum drilling capacity at 52 Kg/mm² tensile strength 40 mm.

- Motor capacity Peak Value: 26KW.

- Motor capacity Continuous load: 22KW.

- Variable speed change unit ensuring rapid feed, drilling feed and rapid return feed.

- Two different pneumatic mist oil-air coolant systems. One for external cooling and one for internal cooling.

- Each axis has an Auto Tool Changer with 4 tool stations.

- The Feed rate for the Cutting speed and Rapid speed can be adjusted between 0-100% during the automated drilling process. The software automatically selects a Rapid speed for fast position towards the material. Once it is in a safe distance from the material, it will change to Cutting speed. This reduces the drilling cycle and improves productivity.

- Independently marking on all three sides is done by a specific scribing tool. There is also DOT option for marking operations (quoted separately).

ATC - AUTOMATIC TOOL CHANGER

Three automatic tool changing units are provided; one for each spindle and each unit has four tool stations. The ATC system enables the machine to change tools quickly and automatically, thus eliminating manual intervention and reducing downtime of the machine. Capacity 8 kg for each station. 4 tools per spindle, total 12 tools. (3 spindle x 4 tools)SPINDLE MOTORS

Drillmaster is equipped with servo motors which provide precise motion capability. The 3 ADM also includes 3 high speed, powerful spindle motors. Mitsubishi (standard) or Siemens brands can be chosenHYDRAULIC VICE

Beams are clamped on the horizontal plane between rollers hydraulically and vertical clamping is performed hydraulically by pressure arms. Deflections and vibrations generated during drilling operation are prevented thanks to 16 hardened rollers that come in contact with the beam from both sides. The material is always clamped in both horizontal and vertical position. Clamping jaws close and open automatically via the CNC controlled program. No special program functions are required. Holes by reference to the working area axis can be drilled as per program.OUT-FEED CONVEYOR

The out-feed conveyor supports beam lengths up to 15m. Rolls centerline distance: 900 mm Width of the rolls: 1500 mm AC drive motor: 2 traverse speeds servo controlMINIMUM QUANTITY LUBRICATION (MQL)

MQL minimizes the environmental impact using 100% natural, vegetable oil-based mixture and eliminating the need for cleaning coolant liquid. Almost-dry processing allows the machine to proceed to the next operation (welding, marking, etc.) without wasting time for coolant liquid disposal. The 5L capacity coolant system for internal cooling of drilling tools and 2 liter of lubricant for installation of the machine are provided. More lubricants can also be provided upon request (5 lt. or 25 lt.).INTELLIGENT DRILLING PROCESS

Spindle speed can be adjustable stepless. The spindle approaches material with a maximum feed rate until it reaches the safety distance from the material. It is decreased to a required feed rate in safety distance and in this way, the drilling cycle time is reduced. AKYAPAK recommends Kennametal KSEM series tools.AUTO-LUBRICATION

The central lubrication system consists of a grease pump and main and intermediate distributors. 54 lubrication points on the machine are lubricated automatically and periodically by this system. It is of 1 liter capacity and designed to resist 250 bar oil pressure. All movable components work smoothly and have a longer lifetime thanks to auto-lubrication system from SKF (Sweden) Company.SAFETY FENCES AND INTERLOCKING DOORS

A safety fence is provided to prevent entering dangerous areas*. The safety fence has various types and dimensions. The interlocking door is integrated with safety fencing. When the sensor notices that the interlocking door is opened, all systems of the relevant zone will be shut down immediately. *The scope of the fencing system depends on the project, it might include additional charges based on the scope of supply.SAFETY SWITCHES

If the doors are opened during production, the machine stops automatically to provide a safe working environment.WIRELESS REMOTE CONTROL

The remote control enables the operator to control some of the machine’s functions remotely and check process in safe. The remote controls vary in models and features.CE AND INTERNATIONAL STANDARDS

All Drillmasters are in compliance with CE regulations and meet the following international standards. Related Directives and Annex: Machinery Directive 2006/42/EC/Annex VIII, Low Voltage Directive 2014/35/EU.- EN ISO 12100:2010,

- EN 12717:2001+A1:2009

- EN 60204-1:2018

SIEMENS 840D SOLUTION LINE

Siemens Sinumerik 840D SL The Sinumerik enables CNC Control to be Integrated with Sequence, Motion, and Robot automation systems Whether drilling, milling, scribing, or tapping, the SINUMERIK 840DSL is a well-suited operator control. The integrated openness of the user interface, CNC and PLC make the SINUMERIK 840DSL distinctive. This means that users can implement their expertise to achieve perfectly tailored control solutions. The open architecture and high computing power allows the CNC functions to be adapted to various innovative machine kinematics in a flexible, rapid and cost-effective way.Key Features

- Accelerated communication speed over the inter-CPU shared memory

- Up to 32 axes with 4 simultaneously controlled axes per CPU.

- Streamlined production with reduced Tact Time and host information system linkage

- 15” Touch screen Monitor- TCU HMI

- Profinet benefits, including noise free, 100Mbps communication

- 15 MB memory capacity

- Continuous to operation in case of electric power cut-off

- USB port for program backup

- Available Languages; English, French, Deutsch

BANDSAW (OPTIONS)

Automatic Miter cutting Horizontal Bandsaw Machine which is fully integrated into the CNC system and can miter cut on a 45-degree left angle and 60-degree right angle. The machine is executed with a free-standing operator control, allowing the machine to operate as a standalone machine, or in production via the DRILLMASTER DM1200 operator control. The Automatic blade tensioning Ensures the blade is always at optimum tension, provides straighter cuts while lowering blade consumption. The saw blade will go down in rapid mode until it gets close to the material reducing the cutting time of different dimensions of materials. During the automated cutting process controlled via the DRILLMASTER DM1200, the material is fed through the machine. For a straight cut, the machine will automatically start cutting after the feeder has reached the required position. For a miter cut, the large CNC controlled turn table, driven by a servo motor, will turn the table to the desired cutting angles. The maximum angles are 45-degree left angle and 60-degree right angle.OPTIONAL FEATURES

AUTOMATIC TOOL AND MATERIAL MEASUREMENT

Material length, width and height are measured automatically by independent measurement systems provided on the machine. An operator sets the material type with dimensions in the program so that the software determines as to how many points the measurement of material height will be performed. The flanges and web heights are measured automatically with a measurement probe. When a beam is clamped horizontally, the width of the beam is measured automatically with a measurement probe. Material length is measured by means of a laser sensor at the exit of the machine. The software stores those dimensions and thus determines the required real dimensions to start the process and more accurate results are obtained. The tool length can also be measured automatically by a laser sensor when a new tool is placed in the tool changer. In this way, material dimensions and drill length are measured automatically, thus saving time and providing operating safety.SCRIBE MARKING TOOL

Marking with scribing tools on up to 4 surfaces of a beam is provided. The marking results are of high readable quality even after painting or blasting processes. Two different tool options are available. Please look at the options section for details.DISC MARKING UNIT

Hydraulic press marking unit is provided as an option. Marking can be made on only an exterior surface of beams by hydraulic cylinder pressure. 40 characters which including letters and numbers are available on the rotating disk and is positioned by servo motor. The marking results are of high readable quality even after painting or blasting processes. Characters height 15 mmTRANSFER TABLES

Transfer tables are integrated into the infeed and outfeed systems to ensure that the material is at the most suitable position for starting the operation and to remove the processed material from the working area safely besides eliminating the need for crane operations. The work-flow safety and continuity are also guaranteed with transfer tables.LIGHT CURTAINS

Light curtains are provided upon request to detect approaches in a dangerous area defined. The multiple curtains cover the dangerous are instead of fence so it has less footprint in the shop and easy for in-shop handling operations. When a light curtain is crossed, all systems of the relevant area will be shut down immediately.BOTTOM SUPPORT UNIT

A bottom support unit is an optional feature provided on the machine to prevent deflections that occur on thin webs, plates, etc. It can be either hydraulic or mechanical. It is recommended if the profile is wider than 600 mm and for the web thicknesses less than 9 mm. The minimum width size in the capacity chart will be 200 mm if hydraulic unit is selected. Capacity chart is valid if the mechanical type is selected.CHIP CONVEYOR

The chips that pile-up in the machine during drilling operations can be disposed with an optional chip conveyor.Additional information

Additional information

| Weight | 100 kg |

|---|