Bomar Proline 520.450 ANC Bandsaw

- Brand: Bomar

In stock

The Bomar Proline 520.450 ANC Bandsaw is an automatic band saw of a double-column construction with CNC control for perpendicular cuts. It is designed for cutting either individual pieces or material in bundles using a hydraulic bundle clamping (optional accessory). The Proline series standard equipment includes automatic downfeed pressure regulation and a 41 mm high band, ensuring precise and straight cutting and increased blade durability. The saw is easily controlled from an independent control panel.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Bomar Proline 520.450 ANC Bandsaw

Bomar Proline 520.450 ANC Bandsaw

You may also like

-

$23,950.00 Excl. GST $26,345.00 Incl. GST Product ID: BOM-WKL-01

Bomar Workline 510.350 DGH Semi Automatic Mitre Cutting Bandsaw

$23,950.00 Excl. GST $26,345.00 Incl. GST -

$11,950.00 Excl. GST $13,145.00 Incl. GST Product ID: BOMAR-410-280G

-

$915.00 Excl. GST $1,006.50 Incl. GST Product ID: PHM-105-PB

-

Product ID: CUTRL-PSM420-600M

-

$12,950.00 Excl. GST $14,245.00 Incl. GST Product ID: USED-COSEN-SH700DM

$12,950.00 Excl. GST $14,245.00 Incl. GST Product ID: USED-COSEN-SH700DM

Description

![]() Bomar Proline 520.450 ANC Bandsaw Operation Manual

Bomar Proline 520.450 ANC Bandsaw Operation Manual

The Bomar Proline 520.450 ANC Bandsaw is an automatic band saw of a double-column construction with CNC control for perpendicular cuts. It is designed for cutting either individual pieces or material in bundles using a hydraulic bundle clamping (optional accessory). The Proline series standard equipment includes automatic downfeed pressure regulation and a 41 mm high band, ensuring precise and straight cutting and increased blade durability. The saw is easily controlled from an independent control panel.

Bomar Proline 520.450 ANC Bandsaw Details

- Solid twin-column construction

- The saw arm is guided through two robust columns utilising linear guide rails for accurate smooth cutting.

- A hydraulic full-stroke main clamping vice and a feeding vice

- Electronic variable blade speed control – Speed range 20-120 m/min

- Carbide blade guides for accurate consistent cutting

- Continuously adjustable saw arm downfeed and pressure control

- Automatic downfeed pressure regulation dependent on the processed material shape and resistance.

- Split vice clamping system allowing for cutting of short materials

- Automatic blade breakage shutdown

- Powerful and reliable 4 kW blade motor

- User friendly control systems

- Large capacity hydraulic system for reliable consistent production

- Precise linear encoder for very accurate material feeding repeatability.

- Driven blade cleaning brush cleaning

Bomar Proline 520.450 ANC Bandsaw Technical Descriptions

Saw Bow

The Saw Bow has been designed with an inclined saw frame designed to guide the blade through the material at the ideal cutting angle, dramatically increasing the cutting speed and prolonging the blade life significantly. This design feature is essential when cutting structural materials square tube or structural steel such as beams and channels.

Columns and saw arm guiding

The saw arm is guided through two robust columns utilizing linear guide rails for accurate smooth cutting.

Saw band drive

The saw band is driven by an industrial 4 kW motor, controlled by a frequency convertor, and by a robust worm-gear unit. The saw band speed may be changed continuously on the control panel within the 20-120 m/min range.

Down feeding and downfeed pressure regulation

The arm downfeed is controlled hydraulically through a hydraulic cylinder and is set on the control panel. The downfeed pressure is permanently monitored by automatic downfeed pressure regulation and adjusted to the material shape. The downfeed pressure regulation sensitivity may be set individually depending on the material shape and quality.

Hydraulic system

The sufficiently dimensioned hydraulic unit is in the front part of the machine where it is easily accessible. The valve block of the hydraulic system is located separately so that it could be simply maintained and adjusted.

Available Accessories

Hydraulic pack clamping – Fitted to both vices (Option $7,500.00 + GST)

Additional top clamping is mounted on main and feeding vice jaws. This optional is useful for processing large volumes of square tube, angle line and other steel sections that can be bundled and clamped uniformly.

Hydraulic blade tensioning indicator (Included)

For easy and correct blade tensioning helping prolong blade life and cutting accuracy.

Micronizer – mist lubrication (Included)

This mist lubrication system applies lubrication directly to the blade tooth set, helping to prolong blade life and reducing the mess caused when using water soluble lubrication oils.

Halogen work light (Included)

The work light is a useful aid for the operator

Pistol washdown gun (Included)

Powerful washdown for easy cleaning maintenance.

Pressure regulation for vice/both vices (Option) $1,200.00 + GST

In some application vice pressure regulation is required for like thin-walled material

Swarf remover (Option) $3,750.00 + GST

The swarf conveyor is useful when cutting large volumes of solid bars or materials.

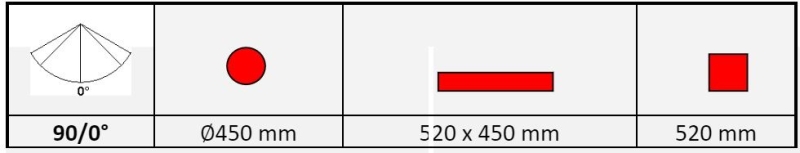

Cutting Parameters

Specifications

| Model | Proline 520.450 ANC |

| Minimum vice opening | 5 mm |

| Material loading height | 780 mm |

| Maximum weight of fed material | 3,460 kg |

| Saw band dimensions | 6,020 x 41 x 1.3 mm |

| Drive output | 4 kW |

| Cutting speed | 20-120 m/min |

| Dimensions: width length height |

3,000 x 2,300 x 2,600 mm

|

| Total weight | 1600 kg |

Additional information

Additional information

| Weight | 900 kg |

|---|---|

| Dimensions | 300 × 230 × 260 cm |

| Shipping Weight | 1600 kg |

Reviews

- industrial band saw

- bandsaw sharpening machine

- industrial band saw for sale

- bandsaw machine

- bandsaw metal cutting machine

- automatic bandsaw machine

- bandsaw cutting machine

- industrial band saw blades

- industrial band saw machine

- industrial horizontal band saw

- industrial metal band saw

- mini bandsaw machine

- bandsaw machine manufacturers

- amada bandsaw machine

- bandsaw machine for meat cutting

- bandsaw machine for sale

- bandsaw machine parts

- bandsaw machine price

- bandsaw machine uses

- big bandsaw machine

- double column bandsaw machine

- industrial band saw manufacturers

- industrial horizontal band saw for sale

- industrial metal cutting band saw

- industrial vertical band saw

- metal bandsaw machine

- metal cutting bandsaw machine

- heavy duty bandsaw machine

- metal cutting bandsaw machine manufacturer

- bandsaw machine for vegetables

- northern industrial band saw

Frequently Bought Together

-

$185.00 Excl. GST $203.50 Incl. GST Product ID: EDGE-EXTNDR-OIL-20L

Request Custom Conveyor Available via Request a Quote