Bomar Individual 520.360 DGANC Fully Automatic Mitre Cutting Horizontal Bandsaw

- Brand: Bomar

In stock

The Bomar Individual 520.360 DGANC a fully automatic band saw of a double-column construction, designed also for double-sided mitre cuts. The outstanding cutting power of the machine results from the following features: a three-sided hardmetal band precision guide, a saw arm laid both-sided on preloaded linear guides, a 34 mm high saw band and lastly, a synchronous running brush for chips disposal. Material downfeed is controlled electromechanically, while material clamping and arm down- feed are controlled hydraulically.

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Bomar Individual 520.360 DGANC Fully Automatic Mitre Cutting Horizontal Bandsaw

Bomar Individual 520.360 DGANC Fully Automatic Mitre Cutting Horizontal Bandsaw

Description

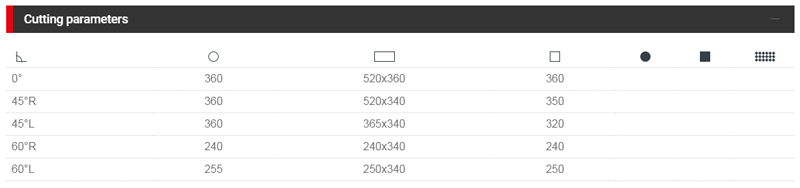

The Bomar Individual 520.360 DGANC a fully automatic band saw of a double-column construction, designed also for double-sided mitre cuts. The outstanding cutting power of the machine results from the following features: a three-sided hardmetal band precision guide, a saw arm laid both-sided on preloaded linear guides, a 34 mm high saw band and lastly, a synchronous running brush for chips disposal. Material downfeed is controlled electromechanically, while material clamping and arm down- feed are controlled hydraulically. The maximum length of an individual feed is 2,300 mm and may be extended up to 6,000 mm upon request. The whole work cycle is completed after the length and number of pieces and angles on each side of a piece have been programmed. The programming is performed in simple steps, and thanks to a large graphic display of individual sections it is easy to control for the user. After switching the machine to the manual mode, all functions of the machine may be controlled separately. All control elements are located on the freely-adjustable control panel. The angles are set electromechanically from 60 ° at the left to 60 ° at the right with ±0.1 ° precision. Material clamping is performed by full-stroke vices. The machine is equipped with a frequency convertor that allows the saw band’s optimal speed to be set against the processed material within the 20–120 m/min range; this signi cantly increases both the saw band lifetime and the machine’s productivity. The saw band is tilted against the vice load surface at a 2 ° angle, which also significantly shortens cutting times and contributes to a longer saw band lifetime. The standard equipment also includes automatic downfeed pressure regulation dependent on the resistance of the processed material, and continuously adjustable arm downfeed. Automatic material shape detection allows the saw arm to move with the maximum speed close above the material, which signi cantly shortens the cycle time. Thanks to its overall design this automatic machine is suitable for cutting pro le materials, especially in the range of frequent double-sided mitre cuts with single feed precision 0.2 mm.

Key features

- Hydraulic full-lift clamping main vice and the feeding vice

- Automatic control of saw band pressure to depth

- Floating seating of the feeding vice

- Freely positionable control panel

Tehcnincal Specification

| Working mode: | automatic |

| Machine type: | Horizontal bandsaw |

| Cut: | Mitre cut |

| Mitre cuts range: | -60° – 60° |

| Drive: | 3 kW, 3×400 V/50 Hz |

| Saw band speed: | 20 – 120 m/min. |

| Saw band dimensions: | 4 780×34×1,1mm |

| Material loading height: | 780 mm |

| Shortest remainder length: | 220 mm at 0° |

| Smallest sawing diameter | – |

Machine dimensions

| Length: | 5 450 mm |

| Width: | 2 350 mm |

| Height: | 2 100 mm |

| Weight: | 3300 kg |

Suitable handling systems

Handling System X/XP

The new X/XP handling system offers unprecedented flexibility for tailoring a handling system to individual needs and conditions. Load capacities and automation levels can be adjusted with perfect flexibility and modified at a later time. Besides the roll conveyor in a regular and propelled version, the X system comprises a rich array of options, from vertical rollers, to length measuring systems all the way to cross conveyor units and shifting devices. The load capacity can be customized by the number of rollers and support feet used. The roll conveyor’s feed profile even allows varying roller and foot distances on the same roll conveyor unit. When needed, additional rollers and/or support feet can be installed at any time.

Micro-spray-system

For ideal cutting of pipes and profiles, the micro-spray unit applies a grease film on the teeth points and lateral sides of the saw band.

Hydraulic bundle clamping device

Device for clamping materials in layers and bundles with the use of an additional vertical clamping unit.

Laser liner

The laser unit copies the exact line in the saw band axis to the material. Laser Liner allows precise adjustment of the marked material.

Workspace lighting

A LED lamp for lighting the workspace, adjustable and mounted on the flexible arm.

Tenzomat

A precise measuring tool for the control of the saw band tension when a new band is installed.

Remote diagnostics and maintenance

Over an Internet connection, status and error messages are transmitted to the factory and decrease downtime.

Pistol for machine cleaning

Tool for fast and easy cleaning of the machine from chips and burrs.

Swarf removal system

Swarf extractor with grabs for an integrated system of collection in Proline machines. The saw is prepared for the chip remover installation, which may be Plug-and-Play connected.

Vice pressure regulation

The pressure regulation of both cylinders is centrally preset, firstly to be avoided of the deformations by thin-walled pipes and profiles.

Additional information

Additional information

| Weight | 3300kg |

|---|

Reviews

- industrial band saw

- bandsaw sharpening machine

- industrial band saw for sale

- bandsaw machine

- bandsaw metal cutting machine

- automatic bandsaw machine

- bandsaw cutting machine

- industrial band saw blades

- industrial band saw machine

- industrial horizontal band saw

- industrial metal band saw

- mini bandsaw machine

- bandsaw machine manufacturers

- amada bandsaw machine

- bandsaw machine for meat cutting

- bandsaw machine for sale

- bandsaw machine parts

- bandsaw machine price

- bandsaw machine uses

- big bandsaw machine

- double column bandsaw machine

- industrial band saw manufacturers

- industrial horizontal band saw for sale

- industrial metal cutting band saw

- industrial vertical band saw

- metal bandsaw machine

- metal cutting bandsaw machine

- heavy duty bandsaw machine

- metal cutting bandsaw machine manufacturer

- bandsaw machine for vegetables

- northern industrial band saw

- band saws horizontal

- horizontal band saws for sale

- metal bandsaw horizontal

- horizontal metal band saws

- steel band saws for sale

- bandsaw blade for metal

- sawmill band saws

- portable band saws

- mini band saws

- second hand meat band saws for sale

- cordless band saws

- band saws gumtree

- automatic band saws

- butchers band saws for sale

- 10 inch band saws

- band saws industrial

- bench band saws

- cnc band saws

- commercial band saws for sale

- commercial band saws

- band saws for sale near me

- woodworking band saws

- band saws melbourne

- parts for band saws

- industrial band saws for sale

- band saws perth

- metal bandsaw australia

- metal cutting bandsaw blades

- wood band saws for sale

- timber band saws for sale

- used metal band saws for sale

- second hand metal bandsaw for sale

- small band saws for sale

- used band saws sale

- band saws used

- meat band saws for sale australia

- cheap band saws for sale

- used metal bandsaw

- second hand band saws

- used meat band saws for sale

- 1400mm bandsaw blade for metal

Frequently Bought Together

-

Product ID: STANDARD-CONVEYOR617MM

-

Product ID: STANDARD-CONVEY-STAND617MM

-

$116.20 Excl. GST $127.82 Incl. GST Product ID: 34MM-BI-BB-20

Arntz Bandsaw Blade for Bomar Model INDIVIDUAL 520.360 DGANC – Length 4780mm x Width 34mm x 1.1mm x TPI

$116.20 Excl. GST $127.82 Incl. GST -

$185.00 Excl. GST $203.50 Incl. GST Product ID: EDGE-EXTNDR-OIL-20L