Bomar 620.460 DGH Semi-Automatic Bandsaw

- Brand: Bomar

In stock

Bomar 620.460 DGH Semi-Automatic Horizontal Bandsaw a Continuous two-sided bevel cuts to 60°, Double mitre cutting and Max Capacity: 620mm

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

Bomar 620.460 DGH Semi-Automatic Bandsaw

Bomar 620.460 DGH Semi-Automatic Bandsaw

You may also like

-

$3,938.00 Excl. GST $4,331.80 Incl. GST Product ID: BOM-PRX-01

-

$26,950.00 Excl. GST $29,645.00 Incl. GST Product ID: BOM-TR-DGH-01

Bomar Transverse 510.330 DGH Semi Automatic Double Angle Bandsaw

$26,950.00 Excl. GST $29,645.00 Incl. GST -

$14,300.00 Excl. GST $15,730.00 Incl. GST Product ID: DGSH-E-MCB

Bomar 320.258 DGH Ergonomic Semi-Automatic Mitre Cutting Bandsaw

$14,300.00 Excl. GST $15,730.00 Incl. GST -

$12,950.00 Excl. GST $14,245.00 Incl. GST Product ID: USED-COSEN-SH700DM

$12,950.00 Excl. GST $14,245.00 Incl. GST Product ID: USED-COSEN-SH700DM -

$92,950.00 Excl. GST $102,245.00 Incl. GST Product ID: SAW720.540.DGH

-

$915.00 Excl. GST $1,006.50 Incl. GST Product ID: PHM-105-PB

Description

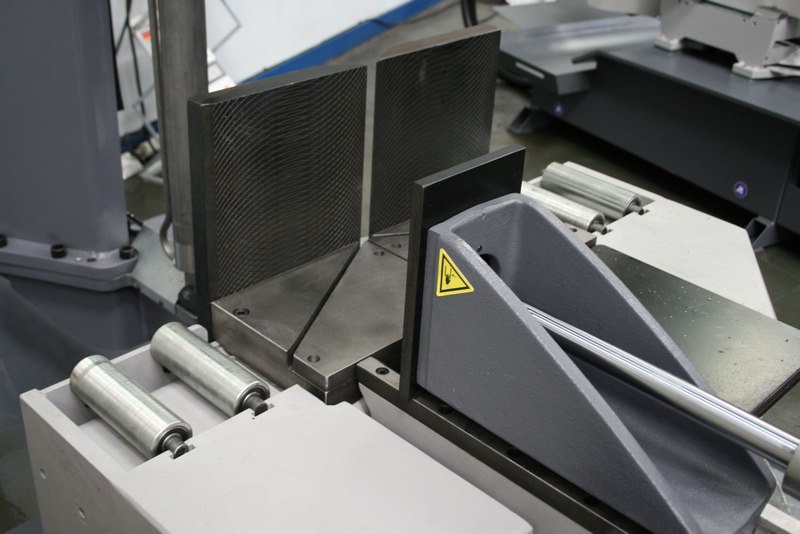

Bomar 620.460 DGH Semi-Automatic Horizontal Bandsaw is a double mitre semi-automatic twin column bandsaw with a bevel range of 60° on both sides. This large capacity machine features a continuous two-sided bevel cuts to 60°, integrated material rollers up to the saw machine’s support tables and powered shavings brushes always synchronized to the saw band speed. The machine Individual 620.460 DGH is a hydraulic, semi-automatic saw of two-column design. Angle cuts can be performed by this machine on both sides in the range -60° and +60°. The machine 620.460 DGH is suitable for universal use in mass production for cutting of profiled and full materials. It is possible to clamp and cut single pieces or bundles of material with hydraulic bundle clamping device (optional accessories). The machine is equipped as standard with automatic control of band pressure to depth providing precise and straight cut beside the 41 mm band. The saw can be operated simply via the control panel attached to the machine base, see machine picture.

Bomar Individual 620.460DGH Details

-

- Two-column structure

- Saw arm is embedded on pre-tensioned linear guideways

- Double-sided arm swiveling with cutting angle within range –60° to the left and +60° to the right

- Hydraulic full-lift clamping vice

- Continuously adjustable speed of the saw band

- Very precision saw band hard-metal guideways ensure cut accuracy

- Continuously adjustable saw arm feed to depth and pressure to depth

- Automatic control of saw band pressure to depth depending on cut material resistance

- Automatic shutdown of the machine due to not tensioned or broken saw band

- Powerful and reliable saw band drive motor 4.0 kW

- Up-to-date control with the text display and the foil keyboard

- Freely positional control panel

- Information regarding the state and process of semi-automatic cycle are shown on the LCD display as dialogues.

- Big hydraulic aggregate

- Machine design in accordance with the applicable CE standards and safety regulations

Bomar Individual 620.460DGH Technical Descriptions

Machine base

The welded structure is resistant to torsion, with the incorporated cooling liquid tank and the removable chip pan.

Saw arm

The stable welded structure resistant to vibrations with the shell structure ensures very quiet run and precise cuts. The saw arm is inclined against the material bearing surface at an angle of 2°, which enables very short cutting channel for sectional materials and beams. Thanks to the short cutting channel it is possible to use a finer tooth and set higher speed of feeding to depth. Service lifetime of the saw band is prolonged, cutting times significantly decrease and cut accuracy increases.

Columns and saw arm guideways

The saw arm is guided by two sturdy columns and is seated on pre-tensioned linear guideways without play. The columns are connected by means of the swivelling bracket and form stable unit with the saw arm. The lifting height adjustment of the saw frame is placed directly on the front column.

Swivelling bracket

The swivelling bracket is connected to the machine base through the stationary wear-resistant bearing. The front guiding segment supports the swivelling bracket and serves for its locking. The swivelling scale is placed right on the guiding segment.

Material clamping

The vice is equipped with a well sized, full-stroke hydraulic cylinder, optionally there is a regulation unit available for sensitive adjustment of the clamping pressure. The movable vice-jaw is mounted on low-wear, hardened guides. The vice can be moved to the left and right according to the mitre position of the saw frame. Material can be cut also in bundle by using a hydraulic bundle clamping device, which also belongs to optional accessories.

Band tensioning

The saw band is tensioned manually. Band tensioning and also possible band breaking are checked electrically. The clamping force can be set right on the saw arm with precise indication on the pressure gauge.

Saw band guideway

The saw band is put on the moving wheels and in the place of cut directed by means of the guiding cubes. The professional tree-sided hard-metal guideway of the saw band guarantees high cut accuracy and long lifetime of the saw band. The left movable cube of the saw band guideway, embedded in the holder on the prismatic guideway, is manually adjustable depending on width of the cut material.

Saw band drive

The saw band is driven by the industrial 4.0kW motor, controlled via the frequency convertor, and by the robust screw gearbox. Saw band speed can be changed continuously via the control panel within range 20–120 m/min.

Feed to depth and control of pressure to depth

Arm feed to depth is performed hydraulically by means of the hydraulic cylinder and is set on the control panel. Pressure to depth is continuously checked via the pressure-to-depth automatic control system and matched to material shape. Sensitivity of pressure-to-depth control can be adjusted individually depending on material shape and quality.

Hydraulic system

The hydraulic unit is sized to be sturdy and is located on well accessible place on the machine front side. The hydraulic system valve block is separated to make maintenance and adjustment easy.

Control element and controller

All control elements are placed on the freely positional users panel. The controller is easy to understand and equipped with plaintext dialogue software.

Working procedure

- Insert and align the material

- Adjust the saw frame to the necessary height

- Move the saw frame to the needed angle and fix the mitre console

- Move the vice if necessary

- Adjust the sensibility of the cutting pressure regulation

- Start the semiautomatic cycle by pressing the START-button

- Adjust the saw blade speed and/or readjust it

- The material is cut through and the saw frame moves up to the adjusted position

- Main drive stops and the vice opens

Possible automation

There are several possibilities for higher automation at the bandsaw individual 620.460 DGH. The saw can be equipped with an electro-mechanical mitre adjustment, set via the controller. Powered conveyors with a NC-controlled measuring unit and a automatic feed reduction as well as stop solution, allow nearly fully automatic cutting even at longer length. In combination with a feeding system it is possible to upgrade the machine to a fully automatic sawing line, exactly made to the need of the customers.

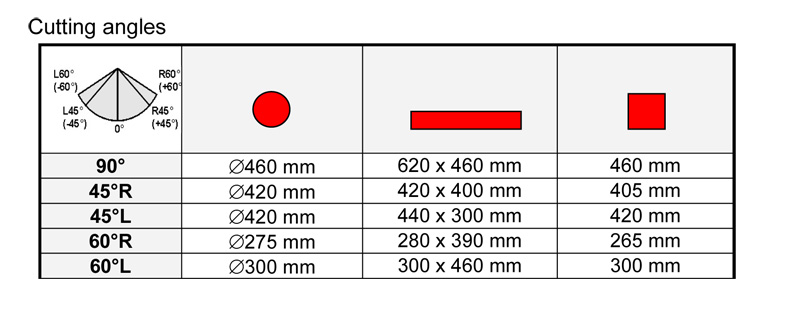

| Cutting angles | |||

| 90° | ø460 mm | 620 x 460 mm | 460 mm |

| 45°R | ø420 mm | 420 x 400 mm | 405 mm |

| 45°L | ø420 mm | 440 x 300 mm | 420 mm |

| 60°R | ø275 mm | 280 x 390 mm | 265 mm |

| 60°L | ø300 mm | 300 x 460 mm | 300 mm |

| Minimal vice opening | 5 mm | ||

| Working bench height | 780 mm | ||

| Saw blade dimension | 6100x41x1,3 mm | ||

| Main drive power | 4,0 kW | ||

| Saw blade speed | 20-120 m/min. | ||

| Dimensions: | Width | 1850 mm | |

| Length | 3000 mm | ||

| Height | 2350 mm | ||

| Total weight | 1850 kg | ||

Bomar Individual 620.460DGH Specifications

| Manufacturer | Bomar |

| Machine Type | Bandsaws / Semi-Automatic Horizontal Bandsaw |

| Operation Type | Semi-Automatic, Twin column, Large Capacity, Straight Cutting, Mitre Cutting |

| Max Capacity Cut Size | 620 |

| Material Type | Sections |

| Materials | Non ferrous, Ferrous |

| Blade Size | 6100 x 41 x 1.3 |

| Blade Speed | 20 to 120 m/min |

| Dimensions | 3100 x 1800 x 2400 |

| Power Supply | 400V, 3 phase |

Additional information

Additional information

| Weight | 1850 kg |

|---|---|

| Dimensions | 300 × 185 × 235 cm |

Reviews

- industrial band saw

- bandsaw sharpening machine

- industrial band saw for sale

- bandsaw machine

- bandsaw metal cutting machine

- automatic bandsaw machine

- bandsaw cutting machine

- industrial band saw blades

- industrial band saw machine

- industrial horizontal band saw

- industrial metal band saw

- mini bandsaw machine

- bandsaw machine manufacturers

- amada bandsaw machine

- bandsaw machine for meat cutting

- bandsaw machine for sale

- bandsaw machine parts

- bandsaw machine price

- bandsaw machine uses

- big bandsaw machine

- double column bandsaw machine

- industrial band saw manufacturers

- industrial horizontal band saw for sale

- industrial metal cutting band saw

- industrial vertical band saw

- metal bandsaw machine

- metal cutting bandsaw machine

- heavy duty bandsaw machine

- metal cutting bandsaw machine manufacturer

- bandsaw machine for vegetables

- northern industrial band saw

Frequently Bought Together

-

$178.50 Excl. GST $196.35 Incl. GST Product ID: 41MM-BI-BB-10

Bandsaw Blade for Bomar Model INDIVIDUAL 620.460 DGH – Length 6100mm x Width 41mm x 1.3mm x TPI

$178.50 Excl. GST $196.35 Incl. GST -

$185.00 Excl. GST $203.50 Incl. GST Product ID: EDGE-EXTNDR-OIL-20L

Request Custom Conveyor Available via Request a Quote