Show Filter

Filter By Category

Blast Nozzle Size

LPM

CFM

Horse Power (HP)

Compressor Type

Mount Type

Saw Type

Blade Diameter(mm)

Bore Diameter(mm)

Tool Type

Kilowatt (kW)

Filter by Type

Filter by Warranty

-

Wila Style Press Brake Tooling Top Punch 800mm

Length: 800mm

Radius: 40mmCapital Machinery carries a wide array of high-quality precision press brake tooling for Wila Trumpf. All our Wila Trumpf press brake tooling are manufactured from premium alloy tool steel. All the wear surfaces of the punches and dies are induction hardened for maximum durability.

Product ID: WTS-800 -

Wila Style Press Brake Tooling Single Vee Die

Length: 800mm

Radius: 40mmCapital Machinery carries a wide array of high-quality precision press brake tooling for Wila Trumpf. All our Wila Trumpf press brake tooling are manufactured from premium alloy tool steel. All the wear surfaces of the punches and dies are induction hardened for maximum durability.

Product ID: WTB-800-1 -

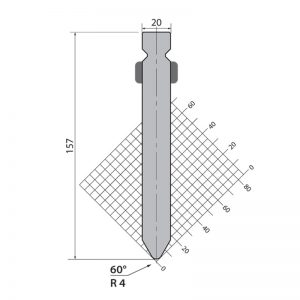

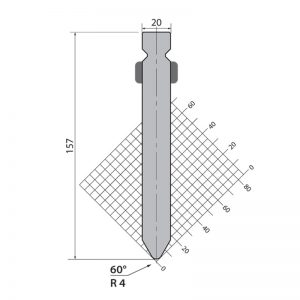

Wila Style HWP 157.60.R4 Top Tool 157 High 60 Deg 500mm Long

1300 kN/m max.

Length:500mm

Radius: 4

Angle: 60 DegreesCapital Machinery carries a wide array of high-quality precision press brake tooling for Wila Trumpf. All our Wila Trumpf press brake tooling are manufactured from premium alloy tool steel. All the wear surfaces of the punches and dies are induction hardened for maximum durability.

Product ID: HWP157.60.R4 -

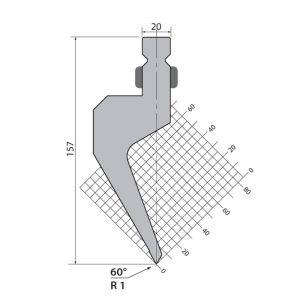

Wila Style HWP 157.60.R1 Top Tool 157 High 60 Deg 500mm Long

700 kN/m max.

Length:500mm

Radius: 1

Angle: 60 DegreesCapital Machinery carries a wide array of high-quality precision press brake tooling for Wila Trumpf. All our Wila Trumpf press brake tooling are manufactured from premium alloy tool steel. All the wear surfaces of the punches and dies are induction hardened for maximum durability.

Product ID: HWP157.60-R1