Industrial Rebar Machinery – A Buyer’s Guide

Industrial rebar machinery is the driving force behind high-volume rebar production facilities. These rugged machines easily cut and bend rebar at a faster rate than portable varieties of machinery and are capable of doing so with large diameter rebar.

There are a lot of industrial rebar machinery brands in the market, but only a select few take the prize for quality and reliability. In order to make an informed buying decision, we compiled a list of our top industrial rebar machines. Furthermore, it is important to consider a few different factors when purchasing an industrial rebar cutter/bender, such as the warranty period, power requirements, portability, space restrictions, and so on. We highlight these points, and more, below.

Key Considerations When Buying an Industrial Rebar Machine

Volume of Work

Industrial rebar cutters/benders are intended for mass production. However, some cutting/bending rebar machinery may not have the required power to allow for multiple rebars to be cut/bent simultaneously. The specifications of the machine will state the number of rebars it can cut/bend with a certain diameter, with some machines capable of handling several rebars at a time, substantially increasing the work output.

Industrial rebar cutters/benders are designed to handle long periods of operation. If the duty cycle of the machine is not explicitly stated, ensure you ask a specialist to ensure the machine you purchase can handle the work you intend on throwing at it.

Power Requirements

Despite industrial rebar machinery being high-torque high-force machinery, here may not be a need to spend on additional equipment to cater for a three-phase supply. Thankfully, many well-known rebar machinery brands can operate on a single-phase 240VAC supply.

However, many models do operate on a three-phase 415VAC supply, such as the TYC HD42A/HD42C reinforced steel rebar cutter (discussed later). This, again, restricts the use of a rebar cutter to a factory environment where three-phase power is most likely to be available.

Since the majority of industrial rebar cutting/bending machines are not fully portable due to their heavy weight and large size, running cabling to a nearby wall outlet should not be a problem. On that note, consideration should be given to the amount of current draw from the rebar machine to ensure it does not continuously trip the electrical supply circuit breakers.

Portability and Space Restrictions

Compared with portable rebar machinery, industrial varieties take up considerably more space and weigh much more. For example, a ICARO P26 Rebar Bender is 68 x 61 x 83 cm and weighs 350kg, whereas a ICARO P70 Rebar Bender is 160 x 115 x 90 cm and weighs 1200kg. It goes without saying that industrial machinery is tough to move around. Nevertheless, these machines can still be used on-site, if required.

With that being said, these machines are best suited to a factory environment where they can be installed in an open space. However, rebar cutting machinery can be slightly different in terms of portability. Some of the ICARO rebar cutting machines come with wheels, allowing for a user to move the machine to a convenient workplace location.

On the same note, they still weigh a considerable amount, with the ICARO C32 Rebar Cutter weighing 470kg. For a space-saving solution, combined rebar cutters and benders are available, which will satisfy all your rebar processing needs in one unit, as opposed to buying a separate rebar cutting and rebar bending machine.

Price

The reliability of rebar machinery is an important deciding factor when looking at the wide variety of brands and options. Since industrial rebar machinery can output considerably more compared with portable/manual rebar machinery, it is worth the investment when you are in a high-volume production environment.

One thing will always stand true, you get what you pay for. Purchase a well-known brand that has been in the market for a while as it ensures you get a quality product. Consider the serviceability, spare parts and service backup. If you cannot afford the costs of downtime and lost production, it would be best to invest wisely at the outset. If you have to pay a little more for a model with industry-backed success, then do it.

Many rebar machines come with additional features such as optional controllers, Bluetooth antenna modules, linear length stops, spiralling forming attachments, and stirrup bending attachments. These features can cost extra, but they allow for the specialised and convenient operation of a rebar machine, thereby, reducing setup times and increasing production efficiencies.

Warranty

A warranty ensures your rebar machinery remains operational for a guaranteed amount of time. The higher the warranty, the more confidence a manufacturer or dealer has in their product. All of the ICARO rebar machinery is supplied with a 24 month extended warranty. At Capital Machinery, we offer maintenance and service on all our products – just another way we ensure 100% customer satisfaction.

The above main points are just a few considerations to keep in mind when purchasing industrial rebar machinery. Other considerations can be found in our portable/handheld rebar machinery buyer’s guide.

Types of Industrial Rebar Machinery

Industrial rebar machines are typically high-production machinery and can be used for processing large volumes of rebar. Many of these machines use high-torque geared motors ranging from 1.85kW and can reach as high as 9.2kW for larger rebar machinery models.

Industrial rebar machinery are designed with efficiency and robustness in mind, capable of sustaining extended periods of work in any kind of environment, always working at peak performance (higher duty cycle times compared with portable rebar machinery).

An industrial rebar cutting and bending machinery is ideal for professional contractors who intend on cutting/bending bars in large volumes, where portable machinery may fall short in providing the same output capacity.

Smaller rebar machines are available for when low volumes of rebar bending/cutting is required (see our buying guide for portable/handheld rebar machines).

In order to gain a better understanding of the available machinery and the pros and cons of each, let’s take a look at the types of industrial rebar machines that are available on the market, namely, individual electric and combination electric rebar cutting and bending machinery. Additionally, we look at a few models under each type:

-

Rebar Combined Cutting and Bending Machinery (11)

-

Portable Rebar Cutting and Bending Machinery (31)

-

Rebar Bending Machinery (23)

-

Rebar Cutting Machinery (17)

-

Rebar Machinery Spare Parts and Accessories (14)

-

Rebar Tying Machinery (3)

-

Rebar Threading Machinery (5)

-

Optional Rebar Machinery Equipment (12)

-

Rebar Spiraller Machinery (3)

-

Rebar Stirrup Bending Machinery (2)

Electric Rebar Cutting Machinery

Industrial rebar cutting machines are for those who intend on cutting a large amount of rebar. Moreover, these machines are designed to be rugged and offer far less restrictions when it comes to cutting a variety of rebar grades (i.e. Common Australian bar grades: 250MPa, 300MPa, and 500MPa).

Furthermore, the high-powered electric motor and metal gearing system (used to increase the cutting force of the blades) ensure reliability and consistency.

Pros

- High duty cycles.

- Suitable for high-volume rebar cutting.

- Single or multiple bar cutting.

- Increased cutting capacity and speed.

- Use durable, multi-edged hardened steel blades.

Cons

- Heavy, but some models come with wheels.

- Cutting blades are consumable items and will need replacing eventually.

ICARO Rebar Cutters

Models: C36, C42, C52, C55, C62, and C70

ICARO Rebar Cutters are manufactured in Italy with CE certification and using global ISO9001:2015 standards, ensuring you receive only the highest quality machine.

Various ICARO models are capable of cutting rebar from 26 mm to 62 mm using toughened heat treated steel shear blades controlled by high-efficiency electric brake motors fitted to helical hardened laminated gearing. These units are supplied with 4-edged blades, allowing for rotation of the cutting faces and easy regrinding or replacing when the cutting faces are worn.

These machines also come with interlocked safety guarding and an adjustable prism bar support, but optional extras such as an adjustable screw locator and a self-lubricating pump are available to order.

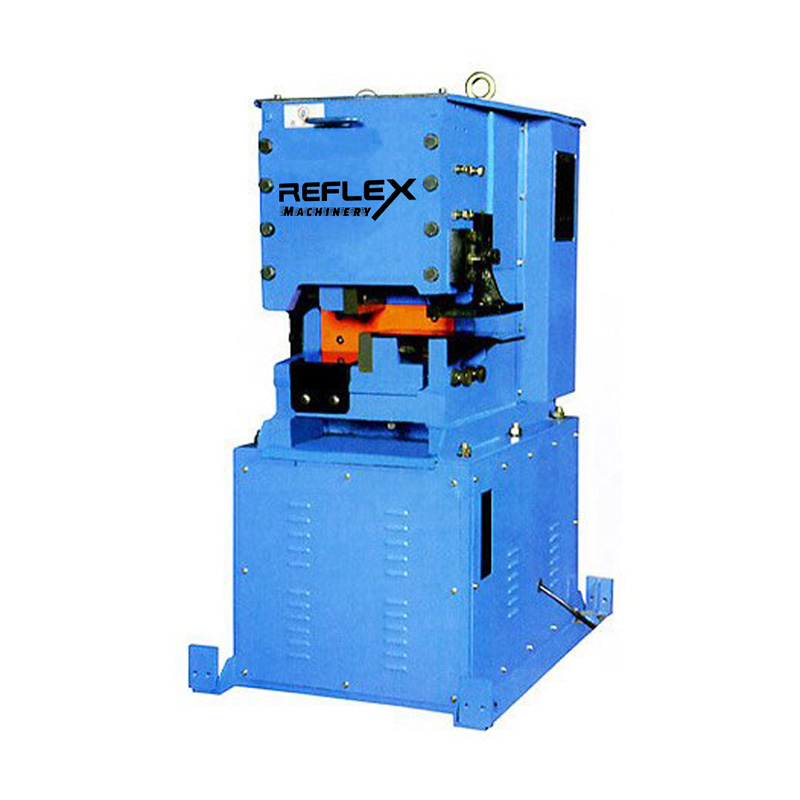

Reflex – HD42A (and HD42C) Reinforcing Steel Bar Cutter

The heavy-duty cutting performance of the Reflex – HD42A/HD42C rebar cutter can handle bar thicknesses of up to 42 mm. Although not as powerful as the larger ICARO rebar cutters (C52 and higher), the 3.7kW electric motor is powerful enough for this machine to cut up to ten 8 mm diameter reinforced steel rebars simultaneously.

The rebar cutting machine’s dimensions are 106 x 72.7 x 137.4 cm and weighs 1300kg, which means you will need a dedicated spot for this machine to operate. Despite the size and weight restrictions,

Electric Rebar Bending Machinery

Industrial rebar bending machinery is an all-round useful piece of machinery, whether you require a large amount of rebar bent to a specific angle or you require a large amount of different angles bent. Moreover, these machines are designed to handle the rigors of factory workshops with many of the internal moving parts protected from dust and grime.

These rebar bending machines come with very high duty cycles and range in bending capacities, from 24 mm diameter rebar through to 70 mm diameter rebar. They come with standard equipment needed to get started, but there are additional features available for purchase to help increase the usability of the machine (i.e. different control units, Bluetooth capabilities, etc.).

Pros

- High duty cycles.

- Suitable for high-volume rebar bending.

- Can be used on a wider range of rebar diameters.

- Increased bending capacity and speed.

- Various additional optional machine features.

- Controller-based.

Cons

- Large physical size and weight.

It is vital to ensure it can handle the work you throw at it. A few questions you should ask yourself are:

- Does the rebar machine cater to the thickness of rebar I intend on bending?

- Do I have the space to fit this machine?

- Do I have the necessary power requirements for the machine?

Refer back to the key considerations section in this guide for further details. Here is a rebar bending machine we pride ourselves in providing.

ICARO Rebar Benders

Models: P32, P36, P42, P46, P52, P55, P62, and P70

The ICARO Rebar Benders are industrial production machines, capable of bending single or multiple bars. Various models are capable of bending rebar with diameters up to 70 mm — more than enough options to handle any high-volume rebar bending work.

As with the ICARO rebar cutting machinery, these bending machines are manufactured with CE certification and according to global ISO9001:2015 quality standards. The powerful reduction gearing is made of tough laminate, which is treated in a special grease bath that does not require any kind of maintenance.

Additionally, the ICARO range of bending machinery comes with a set of standard equipment, such as foot pedal control, supply voltage indicators, and a Bluetooth-ready module. Optional equipment include a spiral forming attachment, a stirrup bending attachment, a linear length stop, a Bluetooth antenna module, and a host of controller options. The Bluetooth module paired with the antenna is mainly used for servicing, allowing you to check the condition of the machine at any moment using a mobile device.

Combined Rebar Cutting and Bending Machinery

These machines combine the best of bending and cutting capabilities into one multi-purpose machine. What this allows is a few interesting benefits. Firstly, these machines can be purchased in a size very similar to a standalone bender/cutter, which saves a ton of space if that is a limiting factor for you.

Secondly, there is a huge cost savings since only one machine needs to be purchased as opposed to two separate machines. Although, despite the pros, there are cons, but they are easily negligible if you know these heavy machines are not going to be moved around and if you know that you will only work within the bending/cutter limits of the machine.

Pros

- More affordable than purchasing two separate units.

- Less space required.

- High duty cycles.

- Various additional optional machine features.

Cons

- These machines can be used either for cutting or bending but cannot be performing both functions at the same time.

- Less cutting capacity for multiple bars than dedicated rebar cutting machines.

ICARO Combined Production Rebar Cutter and Bender

Models: CP26/32, CP30/35, CP38/45, and CP50/54

The ICARO Combined Production Rebar Cutter and Bender is a multi-function machine, allowing the operator to cut and bend rebar on one machine, in one location, making this a great space-saver. It is capable of cutting up to a single 24 mm to 48 mm diameter rebar.

Compared to the previous, individual cutting/bending rebar machinery, combined rebar machines do not have the same cutting capacity for multiple bars. However, the benefit of this machine is, of course, the fact that it takes up nearly half the space as you only need to purchase one machine. It is not only a cost-effective solution, but it would be more than sufficient for most rebar manufacturers sticking to Australian concrete reinforcement standards (AS/NZS4671-2001).

Conclusion

A few of our favourite industrial rebar machinery have been mentioned, making your search for the best rebar machine much easier. These units ranged from our ICARO cutting to bending, and combination machines, with special mention of our TYC reinforced steel rebar cutter.

Our guide should equip you with the right information to make an informed decision on an industrial rebar cutter/bender. The main takeaway points are as follows:

- Consider the volume of work, power requirements, space, portability, price, and warranty of a rebar machine before making a purchase. Do these considerations match your expectations?

- Select a brand you can trust. The ICARO and Reflex products, stocked by Capital Machinery, are trusted brands with years of backed experience.

- Weigh the pros and cons of each industrial machine type to pin point the best solution for your application.

- Ensure the cutting/bending capacity of the machine suits your present and future uses.

When in doubt about a product, speak to a rebar machine specialist to discuss your project and rebar needs in more detail.