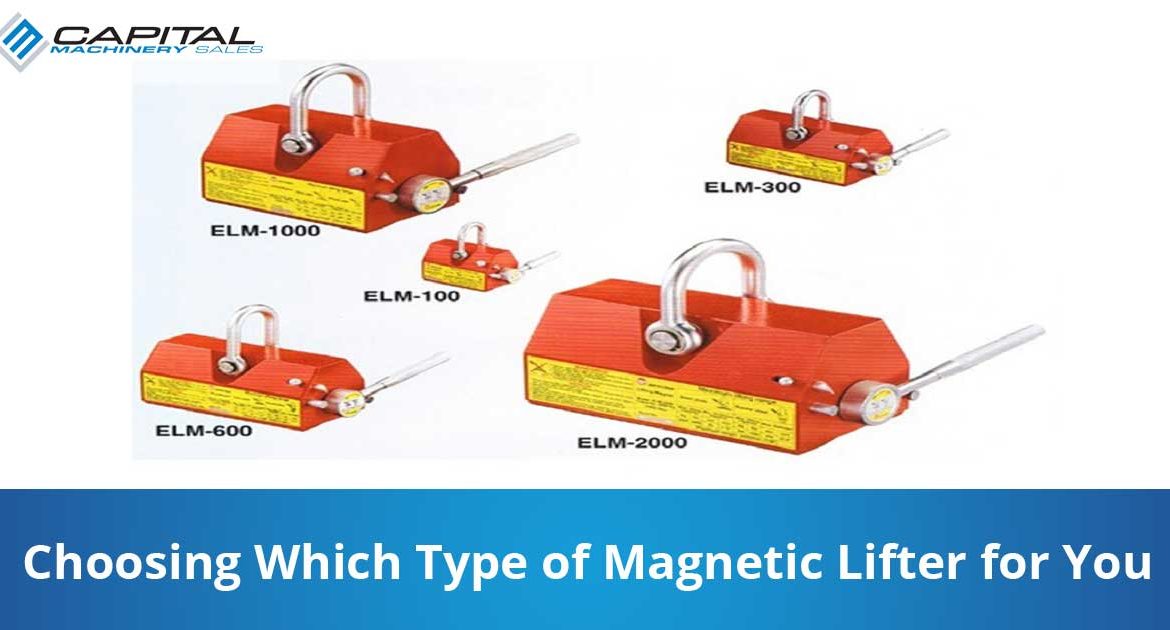

Choosing Which Type of Magnetic Lifter for You

Permanent Magnets vs Electromagnets

Let us acknowledge that both the electromagnets and permanent magnets are made to produce certain types of magnetic fields. The first thing that you need to consider in choosing a magnetic circuit is the type of job that you want to apply the magnet to. If electricity is not readily available, a permanent magnet is the best option. Another thing is when it is not necessary to adjust the magnetic force, a permanent magnet is preferred.

As for electromagnets, they are useful for applications which vary in magnetic strength or for remote controlling. These magnets are to be used for specific tasks of which they are designed for. If you use a different type of magnet for a particular application can result to a serious hazard and safety issues – very dangerous and can be deadly as well.

A lot of these machining operations are made for thick, block-shaped materials. Applications such as these are best for permanent magnets. A lot of shop users know that the best advantage with permanent magnets is the fact that it doesn’t need any electrical hookup or a recharging requirement.

The capacities that a permanent magnet can hold can vary from 330 pounds to 10,000 pounds and can be easily turned on and off with just rotating the lever. There is a safety latch built in to make sure that the permanent magnet is not accidentally turned off while performing a lift. If there are heavier loads, a multiple magnets can be used.

However, in the instance when a part to be machined is very thin – 0.25” or thinner, and the part to be used to the machine operator is a single stack of similar parts, then the electromagnets are best used for this instance provided that the electromagnet has a variable voltage control to manage the intensity to aid in selecting one piece from all the stack.

The self-contained electromagnets are the most cost-effective per pound of lift and a capacity that can extend of up to 10,500 pounds. Self-contained electromagnets operate in 115 volts of AC power. However, there are battery-powered magnets available and uses a gel-contained cell-type battery to expand the lifting capacity and allow handling of flat products, rounds and certain structural shapes. The only disadvantage for electromagnets is that they require periodic charging.